Limestone/Dolomite Crushing Equipment | PF Impact Crusher

Limestone and dolomite are core raw materials supporting the construction, metallurgical, and chemical industries in Saudi Arabia's abundant mineral resources. Efficient crushing of these medium-hard materials is crucial for production efficiency and cost control.

As a manufacturer of mining crushing equipment with 20 years of professional experience, our PF series impact crushers, with their high performance, high reliability, and intelligent design, have become the preferred equipment for limestone/dolomite crushing projects in Saudi Arabia.

This article will provide an in-depth analysis of the technical advantages, application scenarios, and practical cases of the PF impact crusher, offering a comprehensive solution reference for global mining customers.

| Key Words | Limestone/Dolomite Crushing Equipment |

|---|---|

| Product Model | PF Impact Crusher |

| Feed Size | ≤700mm |

| Motor Power | 45-355kw |

| Capacity | 15-800t/h |

| Core Design | The heavy-duty rotor has high inertia, enabling it to crush harder materials and operate more smoothly. |

| Brand | Baichy Heavy Industry |

| Please note: The above table data is for reference only. For specific information, please contact us. | |

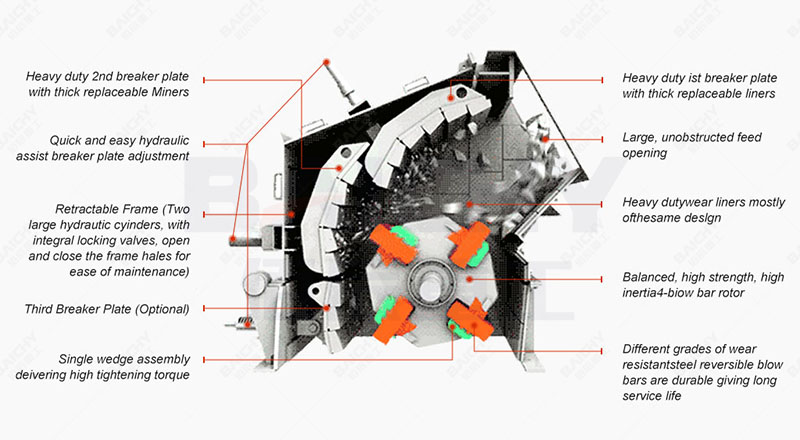

PF Impact Crusher Structure Diagram

Product Advantages

The PF impact crusher is specifically designed for medium-hard materials and possesses the following core advantages:

1. High Efficiency and Energy Saving: Utilizing the impact crushing principle, it achieves a large crushing ratio, excellent finished particle shape, and reduces energy consumption by 20%-30% compared to traditional equipment, aligning with Saudi Arabia's sustainable development goals.

2. High Wear Resistance Design: Key components are made of high-chromium alloy materials, offering strong impact resistance and extending service life by 40% in Saudi Arabia's high-temperature and dusty environment, reducing maintenance costs.

3. Intelligent Control: Equipped with an automatic monitoring system, it adjusts crushing parameters in real time to ensure uniform output particle size (adjustable from 0-40mm), improving production line stability.

4. Flexible Adaptability: Compact structure supports mobile or fixed installation, adapting to perse mining terrains in Saudi Arabia for rapid deployment and production.

PF Impact Crusher Crushing Site

Application Scenarios:

PF impact crushers are widely applicable to the entire limestone/dolomite processing chain in Saudi Arabia:

• Primary Crushing in Mines: Processes large pieces of raw ore, providing uniform feed for subsequent fine crushing.

• Aggregate Production: Used for the preparation of building aggregates (such as concrete raw materials), with a high proportion of cubic particles in the finished product, improving the strength of building materials.

• Metallurgical Auxiliary Material Processing: Crushes dolomite as a flux in steelmaking, with precise particle size control optimizing smelting efficiency.

• Environmental Projects: Processes industrial by-products, supporting the circular economy initiative in Saudi Arabia's Vision 2030.

Project Case: Riyadh Limestone Aggregate Project, Saudi Arabia:

The customer is a large local building materials company with an annual aggregate production capacity of 2 million tons. We configured three PF-1320 impact crushers for them, forming a two-stage crushing production line. After 18 months of operation, the equipment has achieved an average capacity of 350 tons/hour, a finished product qualification rate of 98%, and a 25% reduction in electricity costs. Customer feedback: The replacement cycle of wear parts for the PF crusher has been extended to 3000 hours, significantly improving our return on investment.

FAQ

1. Is the PF impact crusher suitable for processing high-moisture limestone?

Customized anti-clogging designs are supported, but it is recommended that the material moisture content be below 15% to ensure optimal crushing efficiency.

2. Is the equipment suitable for the high temperatures of Saudi summers?

Standard configuration includes a high-temperature resistant motor and a forced cooling system, allowing stable operation at 55°C.

3. Is localized service provided?

Service centers are located in Dammam and Jeddah, providing installation, training, and 24-hour spare parts support.

4. How is the finished product particle size adjusted?

Particle size can be configured within 10 minutes via a hydraulic adjustment system or by changing the screen plate.

Perfect after-sales service

Baichy Heavy Industry provides professional on-site guidance for installation, training of workers, and other services to ensure that customers can use the equipment smoothly.

The company has a complete after-sales service system, which can provide customers with timely technical support and equipment maintenance services to ensure the long-term stable operation of the equipment.

To prevent the rights and interests of customers from being infringed, Baichy Heavy Industry reminds customers: please contact our customer service staff through the official website of Baichy Heavy Industry , or add WhatsApp: 15093222637 ; or send an email to: [email protected] , we will get in touch with you as soon as possible and provide you with the most professional service in the industry.

Baichy Heavy Industry

Baichy Machinery is a factory supplier of mining machinery, mainly focusing on stone crushers, powder grinding mills, and mineral beneficiation plants. We can offer you a free design and completed solutions according to your project.

Baichy Heavy Industry has grown into a high-tech mining equipment comprehensive enterprise, integrating R&D, manufacturing, sales, and after-sales service, Passing ISO9001:2015 quality management system certifications. The main products are mobile jaw crushing plants, construction waste crushing plants, PE jaw crushers, VSI sand-making machines, Symons cone crushers, single-cylinder hydraulic cone crushers, PCX high-fine crushers, grinding mills, ball mills, and full sets of beneficiation equipment with an excellent level.