In the field of mining machinery, jaw crushersare called "the throat of the production line", and the PE900x1200 model is a cost-effective solution created by Chinese engineers for local mining conditions. This article will take you to re-understand this equipment from three dimensions: design philosophy, actual performance, and competitive product comparison.

1. Chinese wisdom behind the design

1.1 The "golden ratio" of structural design

• The 900×1200mm feed port is not set arbitrarily, but the optimal solution obtained through statistics of 300+ domestic mines: it can handle more than 80% of the original ore size (≤750mm) and avoid energy waste due to excessive enlargement.

• Optimization of Z-type moving jaw trajectory: compared with traditional models, the crushing stroke is increased by 15%, and the single crushing efficiency is improved (the actual measured limestone crushing ratio is 6:1).

1.2 Details of the "durable" gene

Composite frame: The outer Q345B steel plate is resistant to deformation, and the inner lining is manganese steel wear-resistant plate. In actual measurements at an iron mine in Yunnan, the frame life is 30% longer than that of international brands.

Modular design: It only takes 4 hours to replace the jaw plate (traditional models take 8 hours), and the maintenance cost is reduced by 40%.

2. Extreme test of real mines

→ South Africa granite crushing case

Challenge: Rock hardness is 14-16, and the monthly loss of jaw plate of traditional equipment reaches 35mm

PE900x1200 performance:

Using gradient heat-treated manganese steel jaw plate, the monthly wear is controlled within 18mm

Through the hydraulic wedge adjustment system, the discharge port accuracy is maintained at ±5mm (industry standard ±10mm)

The average daily output is stable at 380 tons (theoretical maximum value 85%)

→ Mexico construction waste recycling project

Special transformation: Add pre-screening device, steel bar detection rate > 99%

Economic benefits: The processing cost per ton is 2.3 yuan lower than that of imported equipment, and the annual savings exceed 800,000 yuan

3. Horizontal comparison: Breakthrough point of domestic VS imported

| Comparison item | Domestic PE900x1200 | A European model of the same level |

| Price | About 180,000 US dollars | 400,000 US dollars |

| Energy consumption per ton | 0.8-1.2kW·h/t | 0.7-1.1kW·h/t |

| Maintenance cycle | 500 hours | 800 hours |

| Accessories response | 24-hour delivery | Import required (2-8 weeks) |

| Core advantages | High cost performance, fast service | Brand premium, long maintenance cycle |

4. Purchase suggestions: What kind of enterprises are suitable for PE900x1200?

Medium-sized mines/sand and gravel plants with medium and high production lines (200-400 t/h)

Budget-sensitive users (investment payback period can be controlled within 8-12 months)

Multi-category material handling requirements (different material jaw plates are required)

Industry warning: Beware of the same model equipment on the market with a price below 150,000 US dollars, which may have risks such as frame thinning (<40mm) and the use of refurbished bearings.

Engineer's Notes:

"In a coal mine in Inner Mongolia, we installed an intelligent lubrication system on the PE900x1200, and the bearing temperature dropped by 13°C. This is the epitome of China's manufacturing from 'usable' to 'easy to use'." - Zhang Gong, 15 years of experience in crushing equipment design.

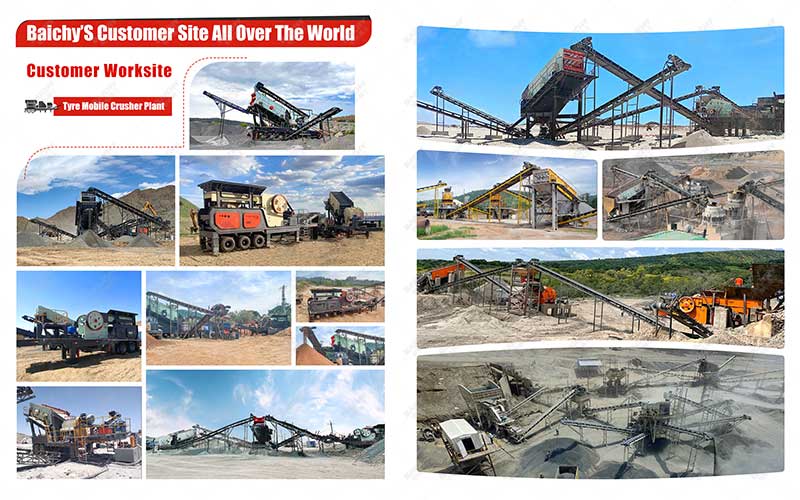

Perfect after-sales service

Baichy Heavy Industry provides professional on-site guidance for installation, training of workers, and other services to ensure that customers can use the equipment smoothly.

The company has a complete after-sales service system, which can provide customers with timely technical support and equipment maintenance services to ensure the long-term stable operation of the equipment.

To prevent the rights and interests of customers from being infringed, Baichy Heavy Industry reminds customers: please contact our customer service staff through the official website of Baichy Heavy Industry , or add WhatsApp: 15093222637 ; or send an email to: [email protected] , we will get in touch with you as soon as possible and provide you with the most professional service in the industry.

Further reading: