Raw mill is generally called cement raw mill, raw mill in cement plant, it refers to a common type of cement equipment in the cement plant. In the cement manufacturing process, raw mill in cement plant grinds cement raw materials into the raw mix, and the raw mix is sent to the cement kiln to make cement clinker, next, clinker and other admixtures will be ground into finished cement by cement mill.

As for the type of raw mill, there are two types including

cement ball mill and

vertical cement mill. In the traditional cement raw mill system, the cement ball mill system is more typical. After technology modification, the vertical cement mill has obvious advantages compared with the cement ball mill, and it is suitable for large cement production lines.

The vertical roller mill (vertical mill for short) in the raw meal mill is an important equipment, used for the grinding and processing of cement raw meal, cement clinker, slag, and cinder. The following is a detailed introduction to the vertical roller mill:

1. Working principle

The working principle of the vertical roller mill is: that the motor drives the grinding disc to rotate through the reducer, and the material falls from the feed port to the center of the grinding disc through the air-locked feeder. At the same time, the hot air enters the mill from the air inlet. As the grinding plate rotates, the material moves toward the edge of the grinding plate under the action of centrifugal force. When passing through the annular groove on the grinding plate, it is crushed by the grinding roller and crushed. After crushing, the material is picked up by the high-speed airflow of the wind ring at the edge of the grinding disc. The large particles fall directly onto the grinding disc for re-grinding. When the material in the airflow passes through the upper separator, under the action of the rotating rotor, the coarse powder falls from the cone hopper to the grinding disc for re-grinding. After grinding, the qualified fine powder comes out of the grinding machine along with the airflow and is collected by the dust collection device, which is the product.

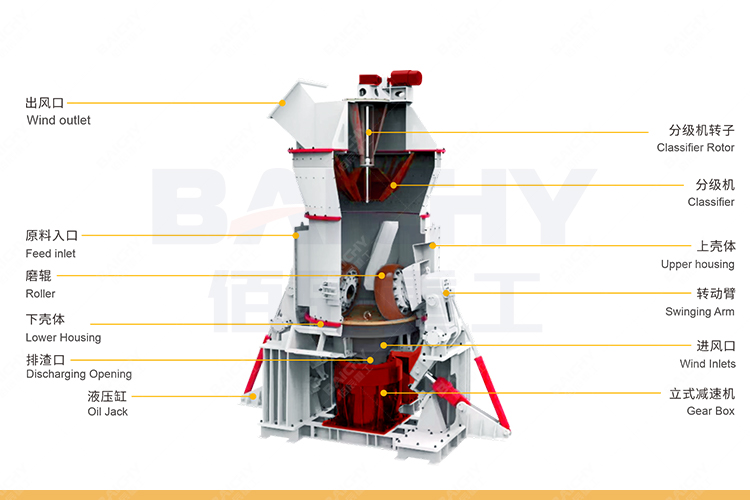

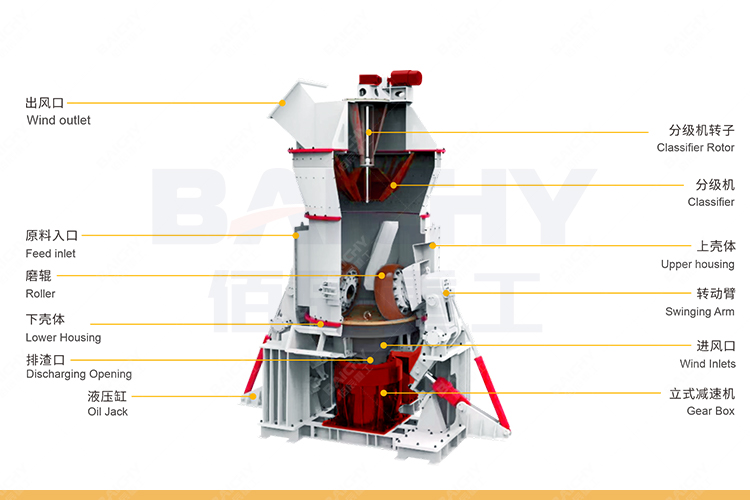

2. Structural composition

Vertical roller mill mainly consists of the following parts:

• Machine body: There is a centering structure that determines the center of rotation between the machine body and the grinding disc device.

Grinding disc device: The bottom is fixed with a rotary guide rail, which can be rotatably supported on the machine body and connected with the transmission device.

• Transmission device: It does not bear the weight of the grinding disc and high axial loads such as grinding pressure, so a general-purpose reducer can be used, which has the advantages of compact structure and reliable operation.

• Grinding roller: a component used to crush and crush materials.

• Separator: An efficient and energy-saving powder selection device used to separate qualified fine powder from the airflow.

In addition, the vertical mill also includes a dry oil lubrication device, air seal pipe, limiting device, water spray system, hydraulic pressure device, and pipeline, grinding roller lubrication device and pipeline, roll turning device, and other components.

3. Technical characteristics

• Efficiency: The vertical mill uses a large roller system to grind materials in large quantities, which is more efficient than traditional grinding mills.

• Energy saving and environmental protection: The vertical mill has a strong drying capacity, less dust, and a compact structure. It integrates grinding, drying, powder selection, and transportation. It is easy to operate, runs smoothly, and has small vibration.

• Easy maintenance: the normal service life of the grinding parts is long, the grinding roller can be lifted and lowered by itself to realize no-load start; the grinding roller can be automatically turned out of the casing by the action of the oil cylinder, making maintenance easy.

4. Application areas

• Vertical roller mills are widely used in the grinding and processing of cement raw materials, cement clinker, slag, and cinder, as well as other industries that require large-scale grinding.

5. Maintenance and overhaul

• In order to ensure normal operation and extend the service life of the vertical roller mill, regular maintenance and inspection are required. This includes the replacement of grinding parts, adjustment of the guide plate gap, enhanced surfacing repair, and replacement of the roller support guard plate.

In summary, the vertical roller mill is an efficient, energy-saving, and environmentally friendly grinding equipment, that is widely used in the grinding process of cement, slag, and other materials. Its unique working principle and structural features give it the advantages of high efficiency, low energy consumption, low noise, and easy maintenance.

Why Choose BAICHY Cement Mill Equipment?

1. Large production capacity: BAICHY has a large area of the workshop of 200,000 square meters, and also has advanced equipment and technology for cement equipment manufacturing. The annual production capacity reaches 150,000 tons of equipment and structure parts and 20,000 tons of casting parts.

2. EPC project: our EPC turnkey project can be applied to both cement plants and cement equipment. EPC project covers project design, cement equipment manufacture, project construction, installation and commissioning, personnel training, and after-sales service.

3. One-stop and customization service: for every client, we will provide an individual solution for different needs of you. Our service includes pre-sale, customization service, and after-sale service!

4. Rich experience: Our cement plant and cement equipment have been exported to many other countries and regions in the world, such as the Philippines, Indonesia, Thailand, Brazil, Angola, Russia, Vietnam, Mongolia etc.

Baichy Machinery is a factory supplier of mining machinery, mainly focusing on stone crushers, powder grinding mills, and mineral beneficiation plants. We can offer you a free design and completed solutions according to your project.

Baichy Heavy Industry has grown into a high-tech mining equipment comprehensive enterprise, integrating R&D, manufacturing, sales, and after-sales service, Passing ISO9001:2015 quality management system certifications. The main products are mobile jaw crushing plants, construction waste crushing plants, PE jaw crushers, VSI sand-making machines, Symons cone crushers, single-cylinder hydraulic cone crushers, PCX high-fine crushers, grinding mills, ball mills, and full sets of beneficiation equipment with an excellent level.