Silica sand, also known as quartz sand, is formed by crushing silica minerals to make sand. The silica sand production line equipment has a mature processing technology and a smooth process flow, so its finished product quality is also high.

There is a large market in the sand and gravel industry. Among them, the silica sand production line includes a silica sand sand production line and a silica sand grinding production line

For the 80t/h silica sandstone sand production line, its configuration mainly includes key links such as raw material processing, crushing, screening, sand making and transportation. The following is a possible configuration scheme:

1. Raw material processing: The raw material bin is used to store silica sandstone, and the raw materials are fed into the production line through the feeder.

Primary crushing: First, use a jaw crusher for coarse crushing, such as PE-600×900 or PE-500×750 models, to crush the raw materials to an appropriate size.

2. Screening: The crushed material is screened by a drum screen or a vibrating screen (such as 2YK1545 or 3YK1548 models) to remove particles that do not meet the requirements.

3. Secondary crushing: Use a cone crusher or VSI sand making machine(such as CS110 and VSI7611) to carry out secondary crushing and shaping of the screened materials to achieve the required finished product particle size (such as 0-30mm).

4. Transport: During the entire production process, conveyors are used to transport materials from one link to another.

Silica sand grinding:

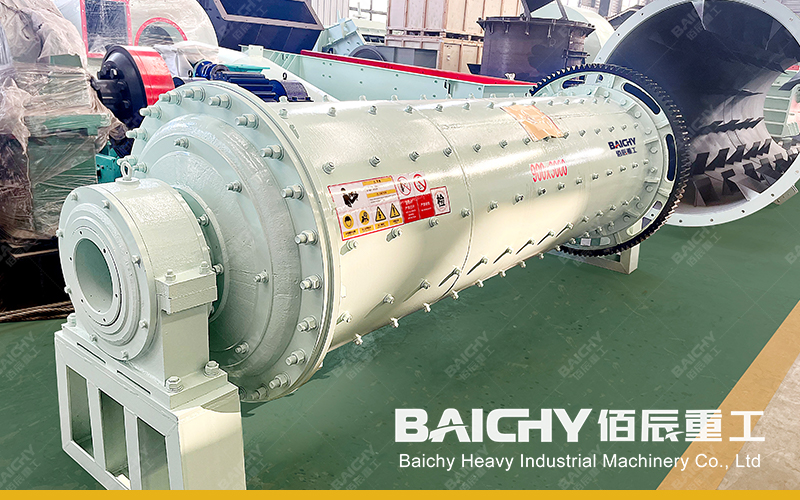

• Ball mill is the key equipment for grinding silica sand after crushing. It can grind silica sand particles to the required fineness.

• Through the interaction between grinding media (such as steel balls) and silica sand in the ball mill, such as impact, rolling, and sliding, silica sand particles are effectively ground into finer particles.

• After grinding by ball mill, the fineness of silica sand is more uniform, which is conducive to subsequent purification processes such as flotation, magnetic separation, etc., thereby improving the purity of silica sand.

Advantages of silica sandstone sand production line

1. Stable output: Through reasonable equipment configuration and process design, ensure that the production line can stably reach a production capacity of 80t/h.

2. High quality of finished products: The silica sand produced by the production line has uniform particle size, good particle shape, and reasonable grading, which meets the standards for construction sand.

3. Low investment cost: Compared with other production line configuration schemes, this scheme has advantages in equipment investment, energy consumption, and labor costs.

4. Environmental protection and energy saving: The production line adopts advanced environmental protection technologies and equipment, such as dust collectors, noise reduction equipment, etc., to ensure environmental friendliness and energy saving and emission reduction during the production process.