When faced with hard rocks, concrete structures, or mineral resources, how do we efficiently break them down to the required size? The answer is the stone crusher—a powerful and indispensable piece of equipment in modern industry. Whether you work in the construction industry or are simply curious about this technology that can turn boulders into smaller pieces, this article will take you deep into the world of stone crushers.

What is a Stone Crusher?

A stone crusher is a machine specifically designed to break large rocks, ores, or concrete into smaller particles. It plays a vital role in mining, demolition, road construction, and industrial processing.

Depending on the material being processed and the crushing requirements, stone crushers come in various types, including jaw crushers, cone crushers, and impact crushers, each with its specific applications and advantages.

How Stone Crusher Works

Although different types of stone crushers differ in structure, they all achieve their crushing function based on several basic mechanical principles:

1. Compression Crushing (Jaw Crusher)

This is the most intuitive crushing method—crushing materials through the compression action between two hard surfaces. 1. **Jaw Crusher:** A jaw crusher has a fixed jaw plate and a movable jaw plate. When the movable jaw plate periodically approaches the fixed jaw plate, the material between them is crushed by compression.

2. Impact Crusher (Impact Mill)

This method uses a high-speed rotating rotor to throw material against the liners inside the crushing chamber, or achieves crushing through mutual collisions between materials. This method is suitable for medium-hard materials and produces excellent cubic particle shapes.

3. Cone Crusher (Grinding Crusher)

This method achieves crushing through continuous rolling and bending. The working principle of a cone crusher is: the moving cone rotates eccentrically within the fixed cone, and the material is crushed through repeated compression and bending between them.

Key Components of a Stone Crusher

Regardless of type, a stone crusher typically includes the following basic components:

• Feeding device: Controls the uniform entry of material into the crushing chamber.

• Crushing mechanism: The core component that performs the actual crushing work.

• Drive system: Provides the power required for crushing.

• Discharge device: Discharges the crushed material.

• Support structure: The mechanical frame of the equipment.

• Control system: Monitors and adjusts the equipment's operating parameters.

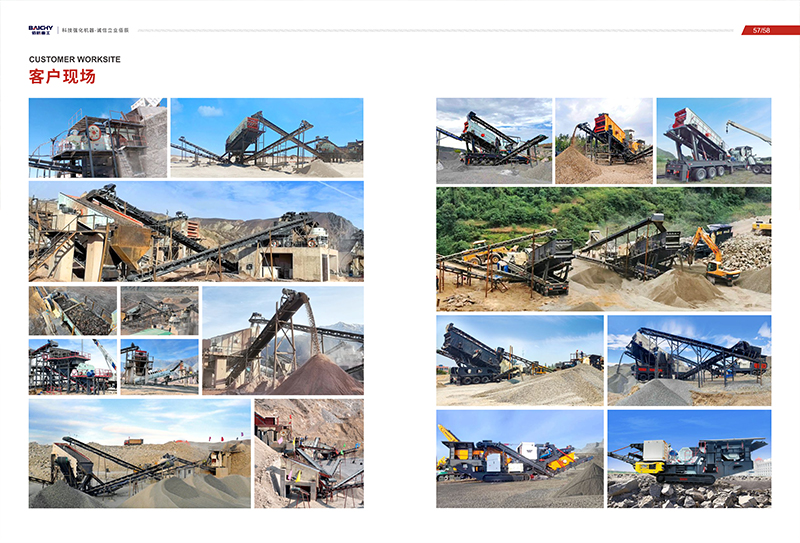

Applications of Stone Crusher

Stone crushers are widely used in modern industry:

• Mining industry: Crushing large ores to a processable size.

• Construction industry: Processing construction waste and achieving resource recycling.

• Road construction: Preparing roadbed materials of various specifications.

• Cement production: Crushing raw materials to a suitable particle size for calcination.

• Metallurgical industry: Preparing raw materials of suitable particle size for smelting.

As a cornerstone of modern industry, the technology of stone crushers is constantly advancing. Modern stone crushers increasingly emphasize energy conservation, environmental protection, automated control, and safety, improving production efficiency while reducing the impact on the environment and operators.

From simple manual crushing to today's highly automated crushing systems, the development of stone crushing technology witnesses a leap forward in human engineering wisdom. The next time you see a stone crusher operating on a construction site or drive on a road paved with crushed stone, you will have a deeper respect and understanding for this "rock destroyer."

If you have further questions about specific types of stone crushers or their applications in different industries, feel free to leave a comment below!