Stone Crushing Plant With Capacity 80-100 TPH

In the sand and gravel aggregate industry, medium-sized stone crushing plants with stable capacity, efficient operation, and controllable costs are the preferred choice for many investors and operators. Among them, a capacity of 80-100 tons/hour is currently a popular choice due to its excellent balance between return on investment and market adaptability.

This article will systematically analyze how to scientifically and efficiently build a stone crushing plant with a capacity of 80-100 tons/hour from scratch, covering core equipment selection, process flow design, key point analysis, and providing a one-stop solution.

I. Core Equipment Selection: The Cornerstone of an Efficient Production Line

A stable and high-yield production line begins with a scientifically sound equipment configuration. For an 80-100 tons/hour crushing line, we recommend the following core equipment combination:

1. Primary Crushing Stage - Jaw Crusher

◦ Role: The "first line of defense" in the crushing line, responsible for the initial and powerful crushing of large raw stones (particle size up to 500-600mm).

◦ Selection Recommendation: Choose a model with a suitable feed opening size, a robust main shaft, and a large crushing ratio. For example, the PE600×900 or PE750×1060 jaw crusher is a classic and reliable choice for this capacity range, capable of stably producing intermediate materials of 150-200mm.

2. Medium and Fine Crushing Stage - Cone Crusher or Impact Crusher

◦ Role: The "main processing center" of the production line, further crushing the coarsely crushed stone into smaller particle sizes (e.g., 31.5mm or below).

◦ Selection Comparison:

▪ Cone Crusher: More suitable for crushing medium to high hardness stones (such as granite and river pebbles), with good wear resistance, low operating costs, and good finished particle shape.

▪ Impact Crusher: Suitable for crushing medium to low hardness stones (such as limestone), producing excellent finished particle shape (mostly cubic), but the hammer wear is relatively fast.

◦ Recommendation: For hard rock, a single-cylinder or multi-cylinder hydraulic cone crusher is a more economical and durable choice.

3. Sand Making and Shaping - Impact Sand Making Machine

◦ Role: The "value enhancer" of the production line, further crushing and shaping some intermediate materials to produce high-value-added, high-quality manufactured sand.

◦ Key Points: Utilizing the "stone-on-stone" or "stone-on-iron" principle, it effectively improves the particle size and shape of the finished sand, enhances product gradation, and meets the requirements of high-standard construction sand.

4. Screening and Conveying - Vibrating Screen and Belt Conveyor

◦ Role: The "circulation and classification system" of the production line.

◦ Vibrating Screen: Typically a multi-stage vibrating screen with 2-3 layers of screens, it accurately classifies the crushed material according to different particle size specifications (e.g., 0-5mm, 5-10mm, 10-20mm, 20-31.5mm).

◦ Belt Conveyor: Connects various devices, forming a smooth material flow network. Its specifications, length, and inclination angle need to be accurately calculated based on the site layout.

II. Scientific Process Flow Design: Four Steps to Build a Closed-Loop Production Line

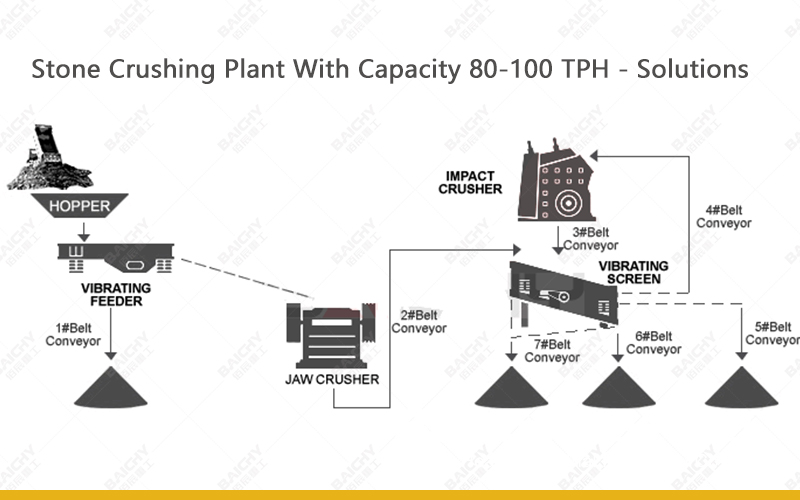

An optimized process design is key to ensuring output, quality, and stability. The classic "three-stage, one-closed-loop" process is recommended:

1. First Stage: Feeding and Coarse Crushing

◦ Raw material silo → Vibrating feeder (uniform feeding) → Jaw crusher (coarse crushing).

◦ Objective: To obtain intermediate products with a particle size ≤200mm.

2. Second Stage: Medium Crushing and Screening (Core of Closed-Loop Cycle)

◦ Material after coarse crushing → Belt conveyor → Cone crusher/impact crusher (medium crushing) → Belt conveyor → Vibrating screen (first-stage screening).

◦ Key Point: Large, unqualified particles on the screen are returned to the medium crusher via a return belt for further crushing, forming a "closed-loop cycle," ensuring uniform feed particle size and reducing the burden on the next stage.

3. Third Stage: Sand Making and Shaping (Optional, for Value Enhancement)

◦ Screening out some medium-sized materials (e.g., 20-40mm) → Impact crusher → Return to vibrating screen or separate screening.

◦ Objective: To produce high-quality manufactured sand and improve aggregate particle shape.

4. Final Screening and Finished Product Storage

◦ Aggregates (pebbles) and manufactured sand of various specifications after final screening → are transported by belt conveyors to different finished product stockpiles or storage silos.

◦ At this point, a complete closed-loop process of crushing, screening, grading, and storage is completed.

III. Key Points of Investment and Construction

1. Preliminary Research is Fundamental: Clarify raw material properties (hardness, moisture content, mud content), target product specifications, and local environmental and land use policies.

2. "Tailor-Made" Design: The equipment layout should be compact and streamlined, reducing material transfer points and lifting height to lower energy consumption and dust. Sufficient space should be reserved for equipment maintenance.

3. Environmental Protection Cannot Be Ignored: A comprehensive dust and noise control plan must be developed, including sealing the entire production line, installing bag filters, and setting up soundproof enclosures or enclosing the plant. This is a prerequisite for project approval and sustainable operation.

4. Electrical and Control Automation: Utilizing a PLC central control system enables one-button start/stop, fault alarms, and remote monitoring, significantly saving labor costs and ensuring production safety and operational efficiency.

Our One-Stop Solution

Faced with the complexity and expertise required to build a medium-sized stone crushing plant, you don't need to handle it alone. We provide complete turnkey solutions from planning to operation for stone crushing plants with a capacity of 80-100 tons/hour:

• Customized Solution Design: Based on your raw materials and market, we customize the most economical process and equipment configuration.

• High-Performance Equipment Supply: We provide a complete set of main equipment, auxiliary equipment, and wear-resistant parts, ensuring quality and compatibility.

• Worry-Free Installation and Commissioning: We dispatch a professional engineering team to guide installation and commissioning until the production line reaches its target output.

• Comprehensive Operational Support: We provide operation training, maintenance manuals, and long-term spare parts supply and technical services.

Inquire now to get a preliminary design and investment budget for your 80-100 tons/hour stone crushing plant!

Core Value: Choosing a professional partner not only provides you with a highly efficient and stable production line, but also ensures long-term, reliable investment security. Let us help you successfully build and operate a benchmark medium-sized stone crushing plant with a more scientific approach and lower overall costs.