In mining, the efficiency of raw material screening directly determines the operational quality and economic benefits of the production line. As the core of mining screening equipment, vibrating screens, with their efficient and reliable performance, have become essential equipment for ore crushing, grading, and cleaning. Whether in coal, metal ore, or sand and gravel aggregate production, vibrating screens achieve precise separation under high-intensity conditions, providing a solid foundation for cost reduction and efficiency improvement.

Why are vibrating screens the preferred choice for mining screening?

1. High Processing Capacity

Using the principle of vibration motor excitation, materials quickly jump and spread across the screen surface, significantly improving screening efficiency. They can easily handle even large volumes of materials with complex particle sizes.

2. Precise Classification

The multi-layer screen design enables simultaneous multi-stage screening, precisely separating materials of varying particle sizes, effectively reducing over-crushing and improving product quality.

3. Strong and Durable, Suitable for Harsh Environments

Utilizing high-strength steel and an anti-clogging design, the equipment is wear-resistant and corrosion-resistant. It operates stably and with minimal failure rates, even in dusty, humid, and high-load mining environments.

4. Energy Saving and Intelligence

Modern vibrating screens are equipped with energy-saving motors and automated control systems. They can flexibly adapt to different material requirements by adjusting amplitude and frequency, reducing energy consumption and labor costs.

Complete Application Coverage

• Ore Screening and Closed-Loop Crushing: Combined with jaw crushers and cone crushers, they form a highly efficient crushing and screening system, optimizing overall production efficiency.

• Sand and Aggregate Grading: Used in sand plants and concrete mixing plants, they precisely separate aggregates of varying sizes, such as 0-5mm, 5-10mm, and 10-20mm.

• Coal and Mineral Cleaning: Combined with a water washing system, they remove impurities and improve resource utilization.

• Tailings Treatment and Recovery: They achieve tailings particle size classification and resource reuse, in line with green mining principles.

Choose us for quality and service.

We offer a variety of vibrating screen models (such as linear screens, circular screens, and high-frequency screens), supporting customized screen mesh and structural designs to meet your specific production needs. From equipment selection, installation and commissioning to after-sales maintenance, our professional technical team will escort you throughout the entire process to ensure the continuous and efficient operation of the equipment.

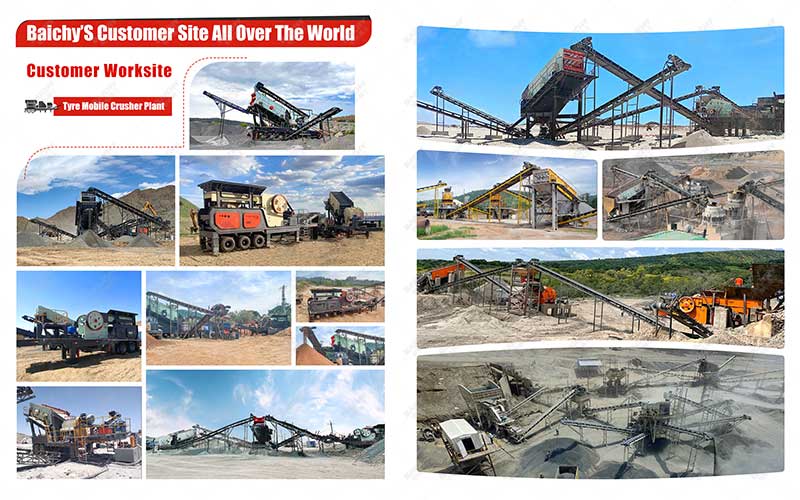

Baichy Heavy Industry – Your Trusted Partner for Seamless Equipment Operation

To ensure optimal performance of your equipment, Baichy Heavy Industry offers:

- Professional on-site installation guidance

- Comprehensive operator training

- 24/7 technical support & maintenance services

Our complete after-sales service system guarantees long-term, stable operation of your machinery with minimal downtime.

Protect Your Rights – Only Use Official Channels

To avoid scams and ensure authentic support, contact us exclusively through:

• Official Website: www.baichychina.com

• WhatsApp: +8615093222637

• Email: [email protected]

Your satisfaction is our priority – expect prompt, professional service every time.

(Note: Beware of unauthorized third parties claiming to represent Baichy. Always verify through official contacts.)