|

Equipment configuration

|

Hopper LC4000X6000, ZSW1349 vibrating feeder, GZG125-4 vibrating feeder, C110 jaw crusher, HPC300 cone crusher, VSI1263 sand making machine, 2YK3080 Vibrating screen, 2YK3070 Vibrating screen,Sand washing machine, Belt conveyor. |

|

Raw materials

|

Limestone, Granite, Basalt, Quartz, River stone etc. |

|

Feed Size

|

Less than 700mm |

|

Finished product

|

Fine sand 0.25-0.35mm, medium sand 0.35-0.5mm, coarse sand 0.5mm. |

|

Capacity

|

250-400t/h |

|

Application

|

In sand quarry, mine, construction site, highway, road and bridge construction, concrete mixing station, water conservancy and hydropower, chemical industry and other industries. |

|

Advantages

|

High production efficiency and low operating cost; Multi-functions and Flexible application; Good shape of finished sand and fineness is adjustable. |

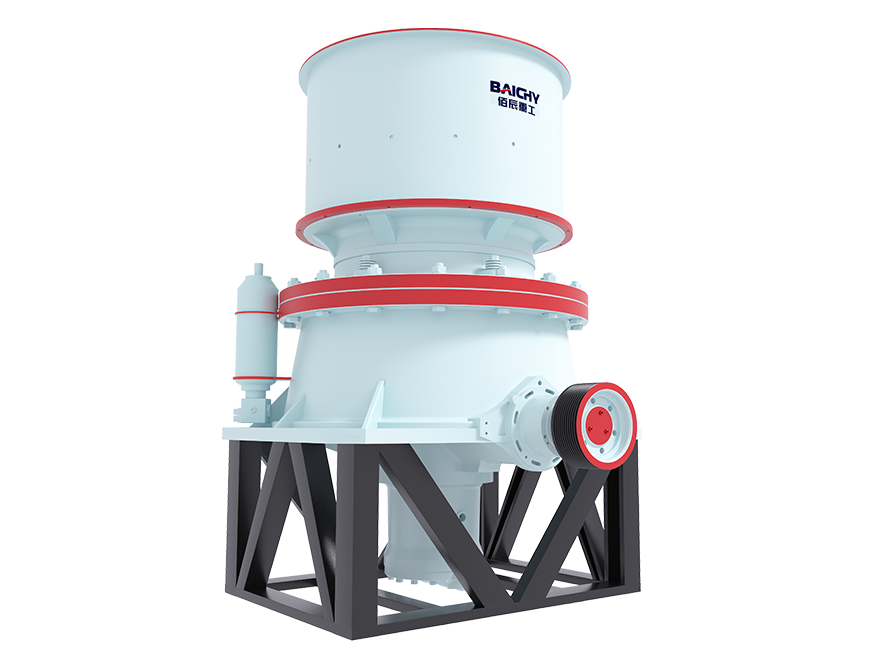

The Single-cylinder Hydraulic Cone Crusher is a high-efficiency crushing machine designed for secondary and tertiary crushing in mining, aggregates, and construction industries. With its simple structure, intelligent hydraulic control system, and low maintenance costs, it delivers reliable performance, high productivity, and energy savings compared to traditional multi-cylinder models.

In industrial production, belt conveyors can be used as the link between production machinery and equipment to form continuous production, so as to realize the continuity and automation of production links, improve productivity and reduce labor intensity.

The belt conveyor can be widely used in mining, metallurgy, coal, transportation, hydropower, and other departments to transport bulk materials or finished items.

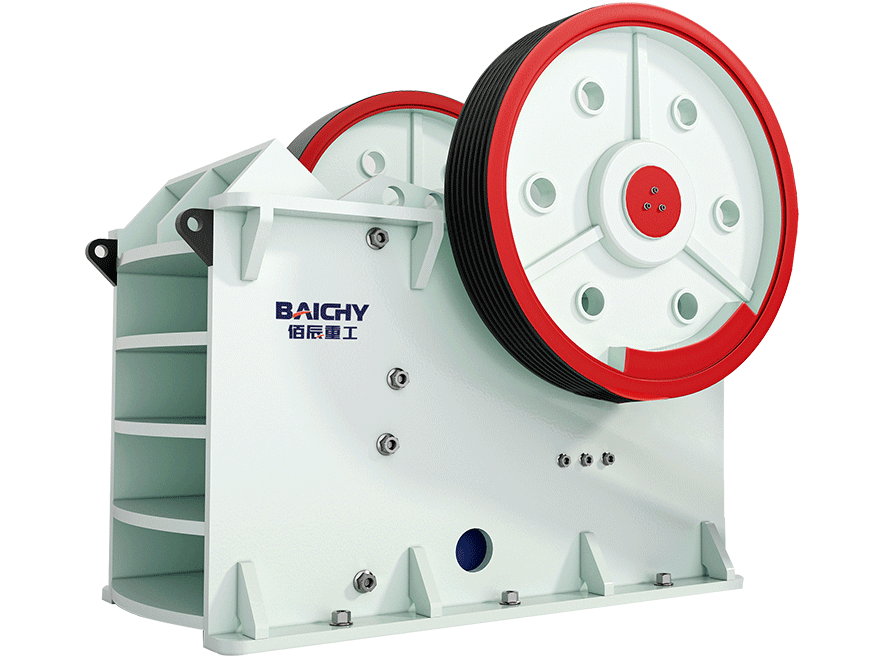

Solve your primary crushing problems in one go!

Baichy Heavy Industry's jaw crusher is specifically designed for crushing hard materials such as granite, basalt, and iron ore. We understand that stable primary crushing is the cornerstone of the entire production line.

With the rapid development of the infrastructure and real estate industries, market demand for high-quality manufactured sand has surged. Traditional small-scale sand-making equipment (e.g., 50-100 tons per hour) can no longer meet the needs of large-scale sand and gravel aggregate plants. Instead, 250-400 t/h sand-making production lines, with their high production capacity, energy efficiency, and environmental friendliness, have become the preferred choice for medium- and large-scale sand and gravel companies.

1. Large-Scale Production: Meets the centralized supply demand for sand and gravel aggregates for large-scale projects (such as high-speed rail and expressways).

2. Energy Saving and Cost Reduction: Utilizes advanced crushing and sand-making processes (such as "stone-on-stone" or "stone-on-iron") to reduce per-ton energy consumption.

3. Environmental Compliance: Equipped with pulse dust removal and noise reduction systems, it meets national green mine construction standards.

• Jaw Crusher (Primary Crushing): Processes large-block materials (≤1200mm), such as granite and basalt.

• Cone Crusher/Impact Crusher (Secondary Crusher): Secondary crushing to ≤50mm, ensuring efficient feeding of the sand making machine.

• Vertical Shaft Impactor (VSI): Core equipment, producing smooth, well-graded sand (fineness modulus 2.4-3.0).

• High-efficiency centrifugal rotor design: Improves crushing efficiency and reduces impeller wear (extending service life by 30%).

• Multi-layer vibrating screen: Accurately classifies particles (0-5mm, 5-10mm, 10-20mm, etc.).

• Pulse bag dust collector: Dust emissions ≤20mg/m³, far below national standards.

Recommended Configuration (for reference)

| Raw Material Hardness | Recommended Equipment Combination | Product Sand Applications |

| High Hardness (Granite) | Jaw Crusher + Cone Crusher + VSI Sand Maker | High-Grade Concrete Aggregate |

| Medium-Low Hardness (Limestone) | Jaw Crusher + Impact Crusher + VSI Sand Maker | Construction Sand, Dry-Mix Mortar |

The four-combination mobile station is widely used in various engineering projects due to its high flexibility, customizability, and efficiency. It can quickly adapt to different working environments and needs, provide efficient and accurate crushing and screening services, and provide strong support for the smooth progress of various engineering projects.

Impact crushers - high-quality impactors, Rock Crushing & Screening Plants, Crushing And Screening Plant, Stone Crusher For Sale

Cone Crushing - High Capacity And Superior Quality. Long Working Life Of Quick-Wear Parts. Stone Crusher Rock Crushing Plant for Sale.