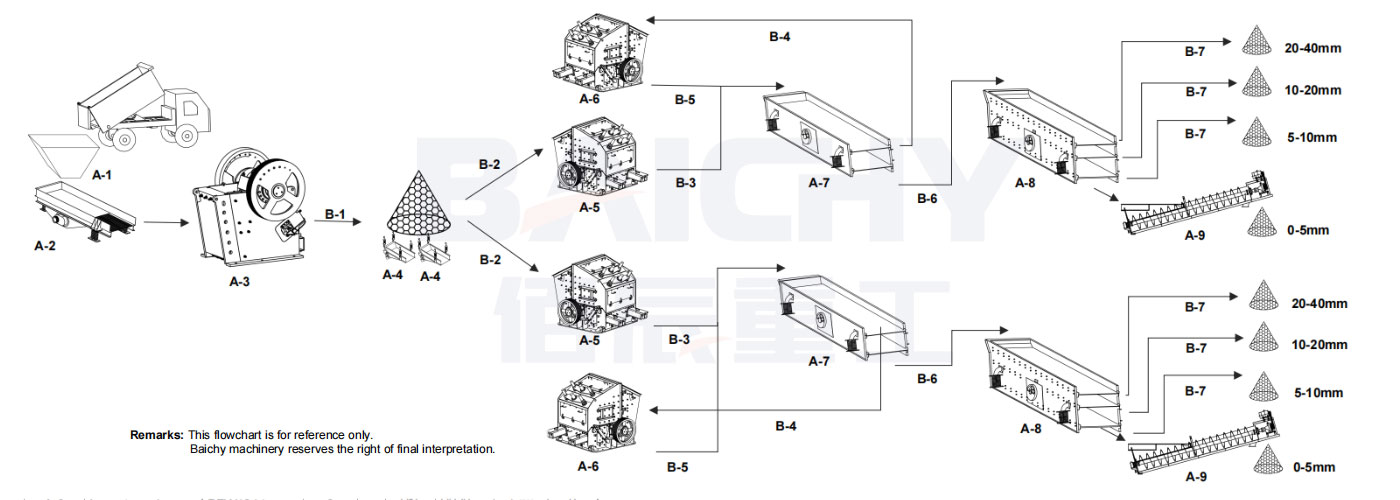

The stone crushing plant is specially designed to produce medium and large-sized sand and gravel aggregates. The core processing capacity reaches 800 tons/hour. It is suitable for hard stones such as granite and basalt. The finished product is adjustable (0-5mm machine-made sand to 20-40mm aggregate).

|

Equipment configuration

|

Vibrating Feeder ZSW1560 | Primary Jaw Crusher PE1200X1500 | PFW 1515 Impact Crusher | YK Vibrating Screen | XL1120 Spiral sand washer | Belt Conveyor |

|

Raw materials

|

Applicable materials: granite, limestone, basalt and other medium and high hardness stones, feed size is usually ≤800mm |

|

Feed Size

|

0-800mm |

|

Capacity

|

800t/h |

|

Finished product

|

Adjustable, common sizes are 0-5mm (machine-made sand), 5-10mm, 10-20mm, 20-40mm, etc. |

|

Design requirements

|

1.The required production capacity 2.The type, hardness, and abrasiveness grade of the crushed material 3.the maximum size of the feed 4.The size of the desired final fraction |

PF series impact crusher is a kind of equipment that uses the high-speed impact principle to crush various medium-hard materials with medium and fine crushing compressive strength not higher than 320Mpa, such as limestone, clinker, slag, coke, coal, etc.

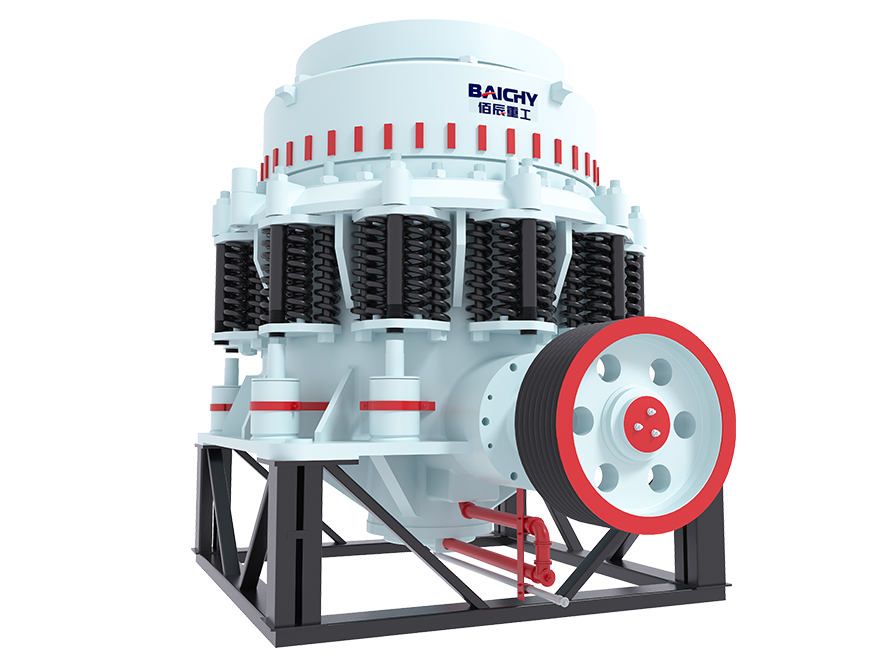

CS Symons cone crusher is a high-performance cone crusher. It is a modern high-performance crusher designed and developed based on the principle of laminated crushing and the concept of more crushing and less grinding, based on the introduction and absorption of foreign technology, according to customer needs.

1. Coarse crushing stage: Use a jaw crusher (feed size ≤800mm), compressive strength ≤320MPa, to ensure efficient crushing of large stones.

2. Medium and fine crushing stage: Configure European version impact crusher (closed-circuit system), discharge ≤50mm, suitable for high hardness materials (such as granite, basalt).

3. Screening system: multi-layer vibrating screen (3-4 layers), screening efficiency ≥90%, accurate classification of 5-10mm, 10-20mm, 20-40mm, and other specifications of aggregate.

Advantages:

• High output matching: 800 t/h can meet the concentrated demand for aggregates in commercial concrete mixing stations and prefabricated component plants.

• Diversified finished products: By adjusting the screen aperture, machine-made sand (0-5mm) and coarse aggregate (5-31.5mm) can be produced simultaneously to improve economic benefits.

Advantages:

• Crushing nearby: Build a crushing station directly in the mining area to reduce transportation costs (saving 3-5 yuan per ton).

• Strong adaptability to hard rocks: The combination of a jaw crusher and an impact crusher can handle high-silicon-content ores (such as granite) with a crushing ratio of 1:10.

The four-combination mobile station is widely used in various engineering projects due to its high flexibility, customizability, and efficiency. It can quickly adapt to different working environments and needs, provide efficient and accurate crushing and screening services, and provide strong support for the smooth progress of various engineering projects.

Impact crushers - high-quality impactors, Rock Crushing & Screening Plants, Crushing And Screening Plant, Stone Crusher For Sale

Cone Crushing - High Capacity And Superior Quality. Long Working Life Of Quick-Wear Parts. Stone Crusher Rock Crushing Plant for Sale.