Jaw crusher has the advantages of strong crushing capacity, high crushing ratio, strong adaptability, flexible adjustment, stable operation, convenient maintenance, energy saving and consumption reduction in the primary crushing stage. It is an indispensable equipment in the fields of mining, metallurgy, construction, etc.

1. Strong crushing capacity: The jaw crusher is designed with a sturdy frame and wear-resistant jaw plate, which can withstand the huge impact force of large pieces of materials and effectively crush rocks and ores with high hardness and strong toughness.

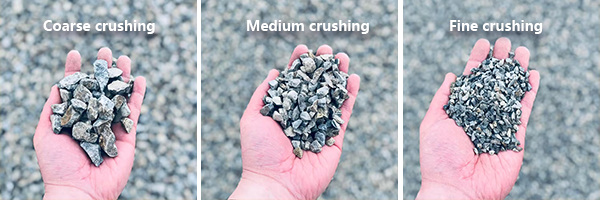

2. High crushing ratio: The crushing chamber of the jaw crusher is reasonably designed to ensure that the material is fully squeezed and sheared during the crushing process, thereby obtaining a higher crushing ratio, that is, the ratio of smaller discharge particle size to larger input particle size.

3. Strong adaptability: The jaw crusher can handle a variety of materials, including hard rock, soft rock, ore, etc., and has a certain adaptability to the water content and mud content of the material.

4. Flexible adjustment: The size of the discharge port of the jaw crusher can be achieved by adjusting the gap between the movable jaw and the fixed jaw, so as to conveniently control the discharge particle size and meet the crushing needs of different users.

5. Stable operation: The jaw crusher has a simple structure and reliable operation. Its driving mechanism usually uses high-quality bearings and gears, which can ensure the long-term stable operation of the equipment.

6. Convenient maintenance: The wearing parts of the jaw crusher (such as the jaw plate) are easy to replace, and the replacement process is simple and fast, which reduces the maintenance cost of the equipment.

7. Energy saving and consumption reduction: With the continuous advancement of technology, modern jaw crushers pay more attention to energy saving and consumption reduction in design, and reduce the energy consumption of the equipment by optimizing the shape of the crushing chamber and improving the crushing efficiency.