What is a jaw rock crusher?

Jaw rock crushers have a wide range of application value in many fields. They can effectively improve production efficiency, reduce production costs, and promote the rational use of resources and sustainable development of the environment.

In the mining industry, jaw crushers are often used to crush large pieces of ore into smaller particles for subsequent grinding, screening and sorting processes. Ores of various hardnesses, such as iron ore, copper ore, gold ore, etc., can also be processed.

Jaw rock crushers have many advantages such as simple structure, large crushing ratio, strong adaptability, stable and reliable operation, convenient maintenance, energy saving and environmental protection, and good economy. These advantages make jaw crushers widely used and recognized in crushing operations.

Performance characteristics of jaw rock crushers

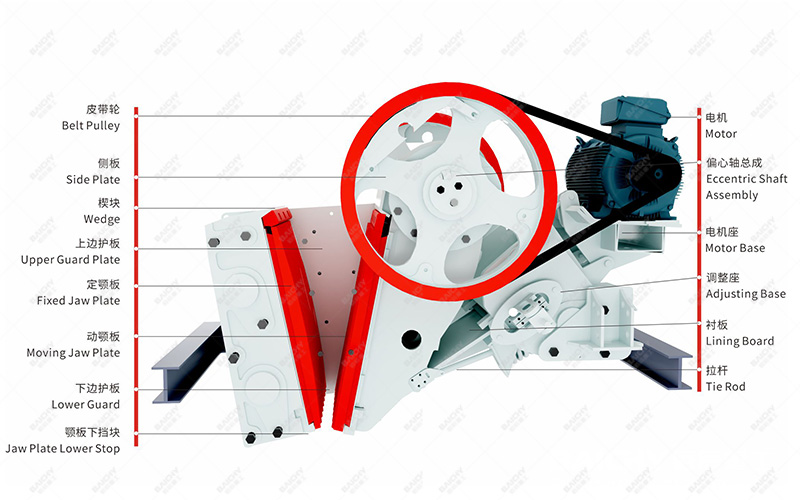

1. Deep crushing chamber and no dead zone: improve feeding capacity and output.

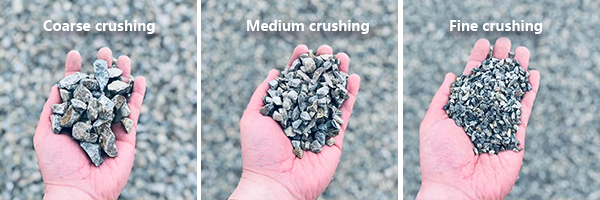

2. Large crushing ratio: uniform product particle size.

3. Gasket-type discharge port adjustment device: reliable and convenient, with a large adjustment range, which increases the flexibility of the equipment.

4. Simple structure: reliable operation and low operating costs.

5. Energy saving: single machine saves 15%~30% energy, and the system saves more than double energy.

6. Low noise and less dust: beneficial to environmental protection.