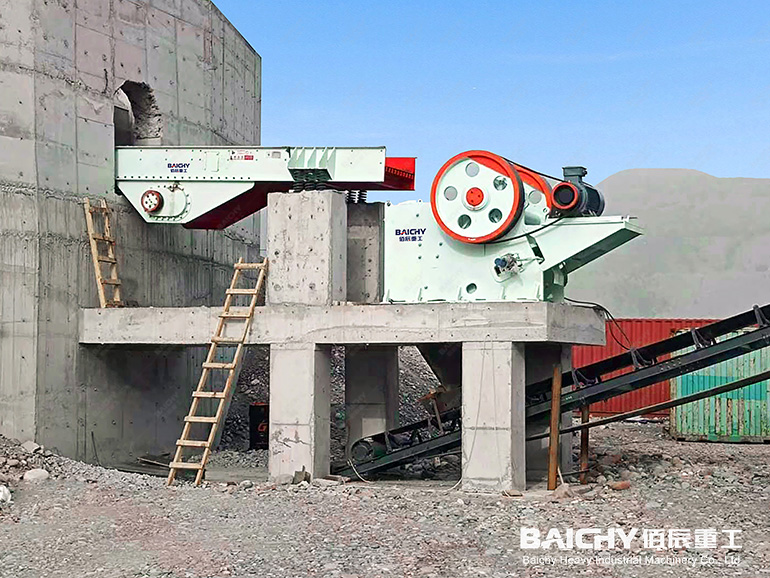

Application fields of jaw crusher plant

The jaw crusher production line is widely used in mining, metallurgy, building materials, highways, railways, water conservancy and chemical industries to crush various ores, rocks and other materials to meet the needs of material particle size in different fields.

Workflow of jaw crusher plant

1. The material is evenly fed into the crushing chamber of the jaw crusher by the feeder.

2. The motor drives the belt and pulley to move the movable jaw up and down through the eccentric shaft.

3. When the movable jaw rises, the angle between the toggle plate and the movable jaw increases, pushing the movable jaw plate to approach the fixed jaw plate, and the material is squeezed, rubbed, and crushed to achieve multiple crushing.

4. When the movable jaw descends, the angle between the toggle plate and the movable jaw decreases, and the movable jaw plate leaves the fixed jaw plate under the action of the pull rod and spring. The crushed material is freely discharged through the discharge port at the bottom of the jaw cavity under the action of gravity.

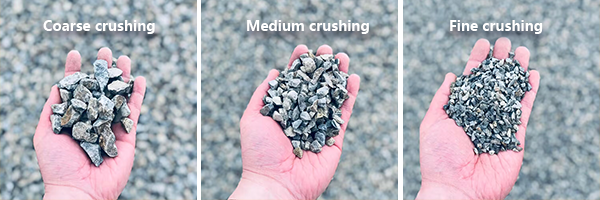

5. The crushed material is sent to the screening machine by the conveyor for screening to obtain products of different particle sizes.