Limestone cone crushing process

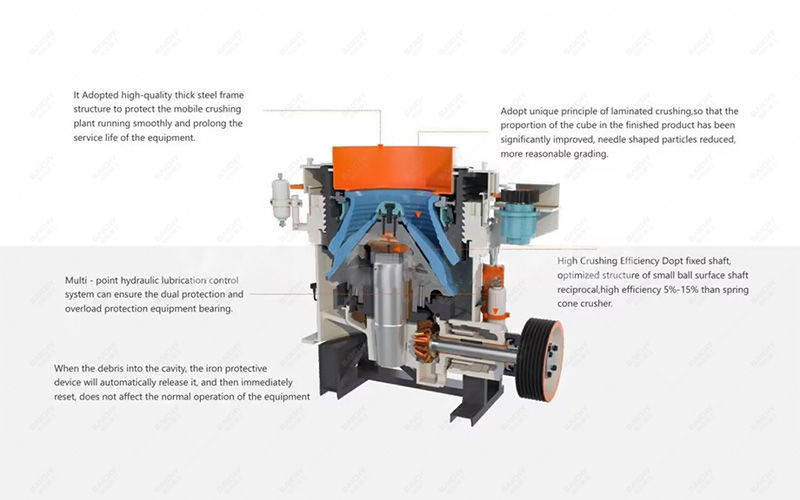

1. Motor drive: The motor transmits power to the drive shaft of the cone crusher through a transmission device such as a pulley or a coupling.

2. Eccentric sleeve rotation: The drive shaft drives the eccentric sleeve to rotate, and the eccentricity on the eccentric sleeve causes the movable cone to produce a swiveling motion.

3. Swiveling of movable cone: Driven by the eccentric sleeve, the movable cone makes a swiveling motion around the center line of the crusher. This movement causes the crushing wall of the movable cone (i.e., the movable cone wall) to sometimes approach the mortar wall of the fixed cone and sometimes leave it.

4. Material crushing: When the movable cone approaches the fixed cone, the space between the crushing wall and the mortar wall gradually shrinks, forming an extrusion effect on the material. At the same time, due to the swiveling motion of the movable cone, the material is also sheared and ground in the crushing chamber. These combined effects cause the material to be gradually crushed into smaller particles.

5. Discharge: The crushed material is discharged through the discharge port at the bottom of the crusher. The size of the discharge port can be adjusted by the adjustment mechanism to control the particle size of the crushed product.