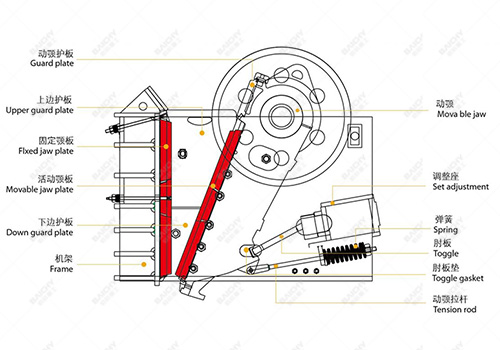

The working part of the fixed jaw crusher is mainly composed of two jaw plates: one is the fixed jaw plate (fixed jaw), which is fixed vertically (or slightly tilted at the upper end) on the front wall of the machine body; the other is the movable jaw plate (moving jaw), which is inclined and forms a crushing chamber (working chamber) with the fixed jaw plate.

The movable jaw plate is connected to the drive device through an eccentric shaft, enabling it to move up and down. When the movable jaw plate moves downward, the material is placed in the crushing chamber and is subjected to the extrusion force between the fixed jaw plate and the movable jaw plate. With the periodic reciprocating motion of the movable jaw plate, the material is crushed by the extrusion, bending and splitting action in the crushing chamber, and finally discharged from the lower part of the crushing chamber.