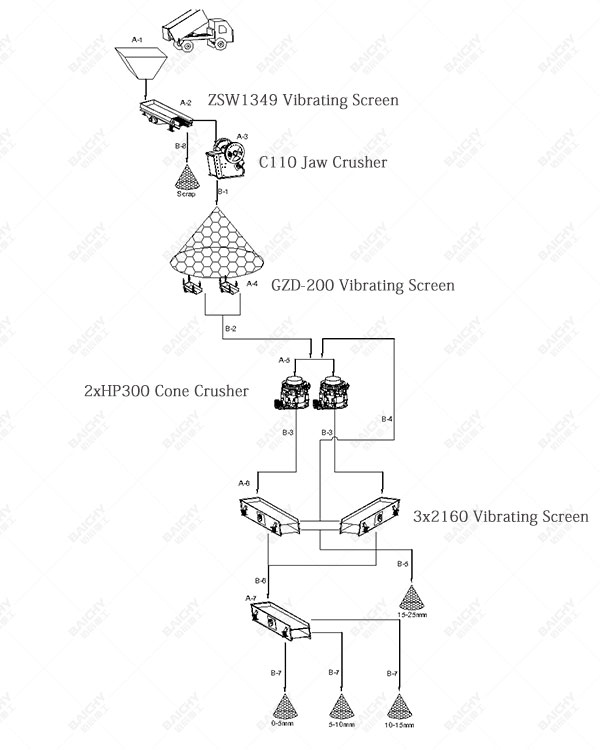

| No. | Equipment | Model | Qty |

|---|---|---|---|

| A-1 | Hopper | LC3000X4000 | 1 |

| A-2 | Vibrating Feeder | ZSW1300X4900 | 1 |

| A-3 | Jaw Crusher | C100 | 1 |

| A-4 | Vibrating Feeder | GZG-200 | 2 |

| A-5 | Cone Crusher | HP300 | 2 |

| A-6 | Vibrating Screen | 2YK2160 | 2 |

| A-7 | Vibrating Screen | 2YK2160 | 1 |

| No. | Name | Length | Qty |

|---|---|---|---|

| B-1 | B1200 | 30m | 1 |

| B-2 | B1200 | (28+8)m | 1 |

| B-3 | B1000 | 23m | 1 |

| B-4 | B1000 | (25+8)m | 1 |

| B-5 | B800 | (25+8)m | 1 |

| B-6 | B1000 | (21+8)m | 1 |

| B-7 | B650 | 25m | 3 |

| B-8 | B650 | 15m | 1 |

In the sand and gravel aggregate and mining crushing industry, the production capacity demand of 250-300 t/h usually means large production lines and high-hardness rock crushing challenges. How to configure an efficient, stable and low-energy crushing production line? This article will deeply analyze the optimal equipment combination and provide a unique production line optimization solution to help you reduce operating costs and improve return on investment.

In the production of large-scale sand and gravel aggregates, production lines with a capacity of 250-300 t/h face three core challenges:

• Low hard rock crushing efficiency (high-hardness materials such as granite/basalt)

• Production capacity bottleneck caused by poor equipment matching

• High energy consumption and maintenance costs

In response to these problems, we innovatively proposed the "three-stage classification + intelligent regulation" solution, which achieves the following by optimizing the equipment combination:

1. Crushing efficiency increased by 30%

2. Energy consumption reduced by 25%

3. Equipment service life extended by 40%

• C100 jaw crusher adopts a "deep V-shaped" crushing chamber design, and the bite angle is optimized to 22° to achieve one-time crushing of large rocks

• Equipped with a hydraulic cavity cleaning system, the material jamming processing time is shortened by 80%

• The dual HP300 cone crushers adopt a "1 main 1 standby" configuration to ensure continuous production

• The lamination crushing principle makes the needle-like content <10%, which is far better than the industry standard

• Three 2YK2160 vibrating screens form a "two-stage screening" system:

The first stage: 50-70mm coarse screen (2 in parallel)

The second stage: 5-30mm fine screen (1)

• The screen is made of polyurethane + rubber composite material, and its life is increased by 3 times

• Geographical location: Ningde City, Fujian Province

• Raw material characteristics: Granite (Mohs hardness 7)

• Capacity requirement: 280 t/h (16 hours/day)

• Finished product specifications: 0-5mm, 5-10mm, 10-20mm, 20-31.5mm

• Raw material characteristics: porous basalt (porosity 15-20%)

• Crushing difficulties: easy to produce over-crushing, the yield of traditional equipment is only 85%

Innovative solution

Two-stage pre-screening system:

• The first screening (30mm) separates fine materials in advance

• The second screening (5mm) uses a probability screen

Special configuration of cone crusher:

• Adjust the HP300 crushing chamber type to "EF" standard

• Add a layer control system

Have Any Questions!

Don't Hesitate To Contact Us AnyTime.

Meet our experts and join discussions about solutions to industry challenges.

Thank you for your interest in Baichy Machinery. If you want to know more about our crushers and industrial grinding equipment.

Contact us now to find out what we can do for you!