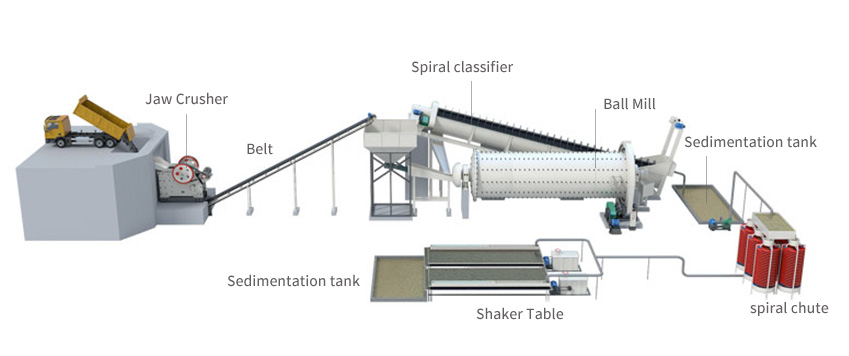

Shaking table can not only be used as an independent beneficiation method, but also often used in combination with centrifugal beneficiation machines, spiral classifiers, spiral chutes, and other mineral beneficiation equipment such as jigging, flotation, and magnetic separation.

Shaking table is widely used in sorting the granularity 2-0.02 millimeters ores of tin, tungsten, gold, silver, lead, zinc, tantalum, niobium, iron, manganese, ferro-titanium and other rare and precious metal ores.

Strong resistance to harsh environment.

The enrichment ratio (the ratio of concentrate grade to raw ore grade) is higher than many other mineral processing methods, up to more than 100 times.

The shaking table is effective in handling mineral materials and can obtain the qualified concentrate and separate the discarded tailings after one separation.

The upper limit of the separation particle size is 3mm, the lower limit can reach 0.4mm, and it is mostly used for separating materials below 1mm.

Compared with the traditional process, the shaking table has low energy, easy management, and the best price.

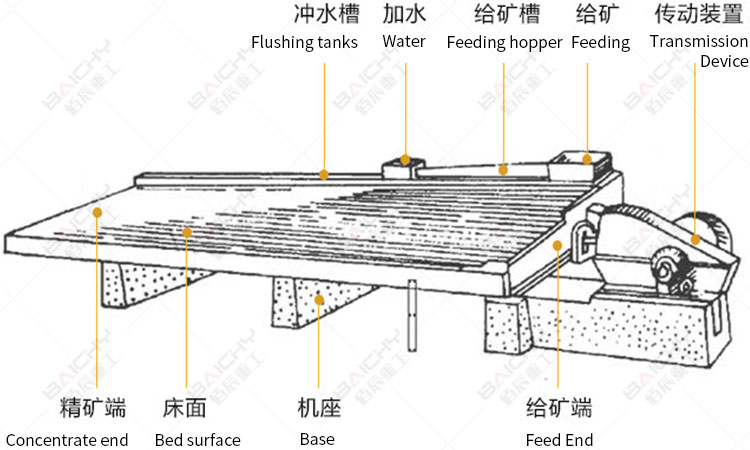

The shaking table is mainly composed of the bed head, transmission device, slope regulator, bed surface, ore feeding tank, flushing tank, and other parts. The longitudinal reciprocating motion of the bed surface is driven by the transmission device. Pushed by the stretching force of the spring, when the rocker moves downward, the bed surface moves backward; when the rocker moves upward, the bed surface moves forward accordingly.

There is a chute on the surface of the bed, and the water flows out from the water tank and the feeding trough in an inclined direction. When the ore slurry enters the feed tank, under the action of water flow and vibration, ore particles of different densities are fan-shaped and distributed on the surface of the bed. Thus the beneficiation process is complete.

| Name | bed surface for coarse sand | bed surface for fine sand | bed surface for slurry | |

| Bed | Length(mm) | 4450 | 4450 | 4450 |

| dimension | transmission end width(mm) | 1855 | 1855 | 1855 |

| concentrate ore width(mm) | 1546 | 1546 | 1546 | |

| Max Feeding Size(mm) | 2 | 0.5 | 0.15 | |

| Feeding volume(t/h) | 30-60 | 10-20 | 15-25 | |

| Feeding density(%) | 25-30 | 20-25 | 15-25 | |

| stroke(mm) | 16-22 | 11-16 | 8-16 | |

| Frequency( t/s) | 45-48 | 48-53 | 50-57 | |

| Cross Slope of Surface | 2.5°-4.5° | 1.5°-3.5° | 1°-2° | |

| mineral dressing area(㎡) | 7.6 | 7.6 | 7.6 | |

| Shape of bed surface | Rectangle | indention | Triangle | |

| Motor Power(KW) | 1.1 | 1.1 | 1.1 | |

| Driving type | Eccentric link structure | |||

| Remarks: Any change of technical parameters, there is no further notice. | ||||

If you need further information,please fill in your questions and comments in the form below.

Representatives from Baichy machinery will be back to you within the hour,thanking you for your support to Baichy machinery