A wet ball mill is an industrial equipment that crushes and grinds materials in a liquid medium (usually water or chemical solution) through grinding media (such as steel balls, ceramic balls, etc.). Its core feature is that the material and liquid are mixed to form a slurry, and ultra-fine grinding is achieved in the rotating cylinder through impact, friction, and grinding.

The wet process can effectively reduce dust pollution and improve grinding efficiency. It is widely used in fields that require ultra-fine particles or subsequent wet processing, such as mining beneficiation, ceramic raw material preparation, chemical material processing, etc.

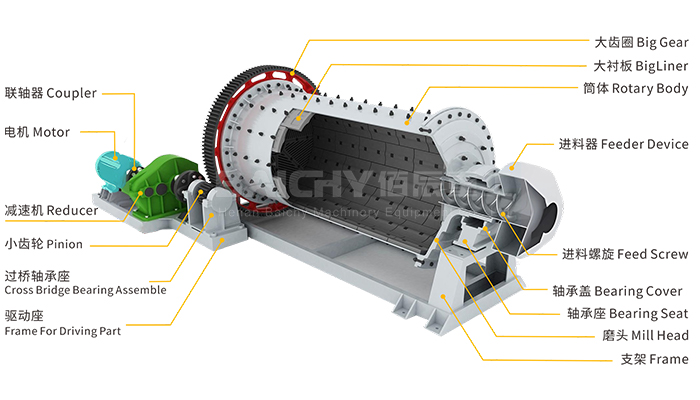

• Cylinder: The main part, lined with wear-resistant materials (such as manganese steel, rubber lining) to protect the cylinder and enhance the grinding effect.

• Inlet/outlet device: Hollow shaft design, wet material is input from the feed end, and slurry is discharged from the discharge end.

• Transmission system: The motor drives the large gear through the reducer to drive the cylinder to rotate.

• Grinding media: Steel balls, ceramic balls, etc., select the material and ratio according to the material characteristics.

gold ore processing plant

wet ball mill

Inner wall lining

Ball mill steel balls

• Media difference: The wet method uses liquid, and the dry method only relies on air.

• Finished product characteristics: The wet method can avoid overheating of the material, and the finished product is finer and more uniform; the dry method needs to control dust.

• Process flow: The wet method requires supporting dehydration equipment, and the dry method directly produces powder.

• Media environment: Liquid (water/solution) is used as a grinding carrier to form a flowing slurry.

• Grinding mechanism: Relying on the rotating cylinder to drive the grinding medium to collide and rub with the material.

• Process purpose: To achieve ultra-fine (micron level) and uniform dispersion of materials.

• Typical applications: wet beneficiation of ore, preparation of ceramic glaze, processing of chemical raw materials, etc.

Wet ball mill is a special equipment that achieves efficient ultra-fine grinding through liquid media. It is suitable for scenes with strict requirements on particle size, environmental protection, and subsequent wet process.

The mining ball mill operates as a whole, the production is safe, the operation is stable, and the grinding effect is remarkable, which is welcomed by many mining processing investors.

The lubrication and dispersion of the liquid medium significantly reduce the adhesion of the material, the contact between the grinding medium and the material is more complete, the impact friction effect is enhanced, and the finished product particle size can reach more than 325 mesh.

The wet process wraps the material in the liquid, eliminating dust pollution and avoiding the risk of explosion (such as handling flammable, explosive, or toxic materials).

After the material and liquid are mixed, a flowing slurry is formed, which does not require shutdown for discharge, supports automated continuous production, and improves overall processing efficiency.

The liquid medium can absorb the heat generated during the grinding process to prevent the material from being denatured or oxidized due to high temperature, especially suitable for heat-sensitive materials (such as certain chemical raw materials or biological agents).

Grinding process: When the cylinder rotates, the internal grinding media (steel balls, ceramic balls, etc.) and the materials are lifted to a certain height under the action of centrifugal force and then thrown down, crushing the materials through impact, friction, and grinding.

Advantages of the wet method: Adding water or other liquids to form a slurry reduces material adhesion, reduces dust, and improves grinding efficiency and product fineness.

| Model | Cylinder Rotating Speed (r/min) |

Ball weight (t) |

Feeding Size (mm) |

Discharging Size (mm) |

Capacity (t/h) |

Power (kw) |

Total Weight(t) |

| Ф900×1800 | 36-38 | 1.5 | ≤20 | 0.075-0.89 | 0.65-2 | 18.5 | 5.85 |

| Ф900×3000 | 36 | 2.7 | ≤20 | 0.075-0.89 | 1.1-3.5 | 22 | 6.98 |

| Ф1200×2400 | 36 | 3 | ≤25 | 0.075-0.6 | 1.5-4.8 | 30 | 13.6 |

| Ф1200×3000 | 36 | 3.5 | ≤25 | 0.074-0.4 | 1.6-5 | 37 | 14.3 |

| Ф1200×4500 | 32.4 | 5 | ≤25 | 0.074-0.4 | 1.6-5.8 | 55 | 15.6 |

| Ф1500×3000 | 29.7 | 7.5 | ≤25 | 0.074-0.4 | 2-5 | 75 | 19.5 |

| Ф1500×4500 | 27 | 11 | ≤25 | 0.074-0.4 | 3-6 | 110 | 22 |

| Ф1500×5700 | 28 | 12 | ≤25 | 0.074-0.4 | 3.5-6 | 130 | 25.8 |

| Ф1830×3000 | 25.4 | 11 | ≤25 | 0.074-0.4 | 4-10 | 130 | 34.5 |

| Ф1830×4500 | 25.4 | 15 | ≤25 | 0.074-0.4 | 4.5-12 | 155 | 38 |

| Ф1830×6400 | 24.1 | 21 | ≤25 | 0.074-0.4 | 6.5-15 | 210 | 43 |

| Ф1830×7000 | 24.1 | 23 | ≤25 | 0.074-0.4 | 7.5-17 | 245 | 43.8 |

| Ф2100×3000 | 23.7 | 15 | ≤25 | 0.074-0.4 | 6.5-36 | 155 | 45 |

| Ф2100×4500 | 23.7 | 24 | ≤25 | 0.074-0.4 | 8-43 | 245 | 56 |

| Ф2100×7000 | 23.7 | 26 | ≤25 | 0.074-0.4 | 12-48 | 280 | 59.5 |

| Ф2200×4500 | 21.5 | 27 | ≤25 | 0.074-0.4 | 9-45 | 280 | 54.5 |

| Ф2200×6500 | 21.7 | 35 | ≤25 | 0.074-0.4 | 14-26 | 380 | 61 |

| Ф2200×7000 | 21.7 | 35 | ≤25 | 0.074-0.4 | 15-28 | 380 | 62.5 |

| Ф2200×7500 | 21.7 | 35 | ≤25 | 0.074-0.4 | 15-30 | 380 | 64.8 |

| Ф2400×3000 | 21 | 23 | ≤25 | 0.074-0.4 | 7-50 | 245 | 58 |

| Ф2400×4500 | 21 | 30 | ≤25 | 0.074-0.4 | 8.5-60 | 320 | 72 |

| Ф2700×4000 | 20.7 | 40 | ≤25 | 0.074-0.4 | 22-80 | 380 | 95 |

| Ф2700×4500 | 20.7 | 48 | ≤25 | 0.074-0.4 | 26-90 | 480 | 102 |

| Ф3200×4500 | 18 | 65 | ≤25 | 0.074-0.4 | 95-110 | 630 | 149 |

| Ф3600×4500 | 17 | 90 | ≤25 | 0.074-0.4 | 115-170 | 850 | 169 |

| Ф3600x6000 | 17 | 110 | ≤25 | 0.074-0.4 | 120-200 | 1250 | 198 |

| Ф3600x8500 | 18 | 131 | ≤25 | 0.074-0.4 | 45.8-256 | 1800 | 260 |

| Ф4000x5000 | 16.9 | 121 | ≤25 | 0.074-0.4 | 45-208 | 1500 | 230 |

| Ф4000x6000 | 16.9 | 146 | ≤25 | 0.074-0.4 | 65-248 | 1600 | 242 |

| Ф4000×6700 | 16.9 | 149 | ≤25 | 0.074-0.4 | 75-252 | 1800 | 249 |

| Ф4500×6400 | 15.6 | 172 | ≤25 | 0.074-0.4 | 84-306 | 2000 | 280 |

| Ф5030×6400 | 14.4 | 216 | ≤25 | 0.074-0.4 | 98-386 | 2500 | 320 |

| Ф5030×8300 | 14.4 | 266 | ≤25 | 0.074-0.4 | 118-500 | 3300 | 403 |

| Ф5500×8500 | 13.8 | 338 | ≤25 | 0.074-0.4 | 148-615 | 4500 | 525 |

Mining: Wet beneficiation and crushing of gold, copper, and iron ore.

Ceramics/Glass: Ultrafine grinding of raw materials (such as kaolin and feldspar) into slurry.

Chemicals: Wet dispersion and crushing of materials such as calcium carbonate and graphite.

New Energy: Slurry preparation of positive and negative electrode materials for lithium batteries.

Ideal range: The proportion of solid materials is usually 60%-75% (specific adjustment due to material density).

Adjustment method: Through the dynamic balance of feed rate and liquid addition, too high a concentration will reduce efficiency, and too low a concentration will waste energy.

Regular inspection: Wear of liner and steel ball (it is recommended to replace wear parts every 3-6 months).

Lubrication system: Bearings and gears need to be regularly filled with high-temperature grease to prevent overheating.

Anti-corrosion treatment: Equipment that comes into contact with chemical solutions needs to use corrosion-resistant linings (such as rubber or ceramic).

Source of energy consumption: Liquid media increases the load on the cylinder, and wastewater needs to be treated later.

Energy-saving measures:

• Use variable frequency motors to adjust the speed to match the needs of different grinding stages.

• Wastewater recycling systems (such as sedimentation tanks + filtration devices) reduce resource waste.

If you need further information,please fill in your questions and comments in the form below.

Representatives from Baichy machinery will be back to you within the hour,thanking you for your support to Baichy machinery