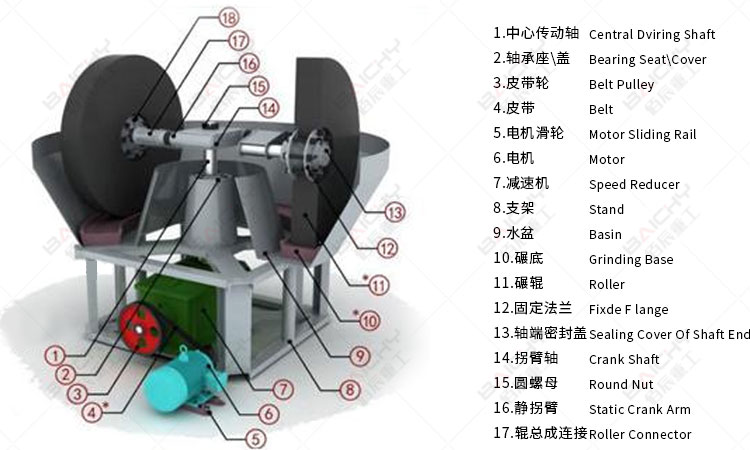

As an industrial equipment, wet pan mill is mainly used for wet grinding and crushing materials. It is a kind of equipment that grinds and crushes materials through a water medium. It uses a grinding disc and a grinding wheel (or similar parts) to process materials in a wet environment. In the metallurgical industry, wet disc mills can be used for wet grinding and crushing of ores to improve the leaching efficiency and smelting effect of ores.

Wet pan mill equipment reduces dust generation, improves the working environment, and helps to evenly mix and refine materials; it uses the lubrication of water to reduce energy consumption and improve grinding efficiency; by adjusting the grinding time and the parameters of the grinder, the crushing fineness of the material can be controlled to meet the needs of different industries; it is suitable for the mining industry.

A wet pan mill is the best equipment to replace a ball mill because of its low investment, high output, easy use and maintenance, and quick cost recovery.

Reduces dust generation, improves the working environment, and helps to evenly mix and refine materials.

Uses the lubricating effect of water to reduce energy consumption and improve grinding efficiency.

By adjusting the grinding time and the parameters of the grinder, the fineness of the material can be controlled to meet the needs of different industries.

Applicable to multiple industries such as mining, building materials, chemicals, and cement.

Definition: Wet pan mill is a device that grinds and crushes materials using a water medium. It uses a disc and a millstone (or similar components) to process materials in a wet environment.

Working Principle: In a Wet pan mill, a certain amount of water is first added to the device, and then the material is put into the disc. Through the rotation of the disc and the action of gravity, friction, and impact are generated between the material and the abrasive (which may be a millstone or other form of abrasive), thereby achieving the effect of grinding and crushing. This wet grinding method helps to reduce dust generation, improve grinding efficiency, and facilitate further processing of the material.

| Model | 1600 | 1400 | 1300 | 1200 | 1100 | 1000 | 900 |

| Dia.of grinding wheel (mm) | 1600±10 | 1400±10 | 1300±10 | 1200±10 | 1100±10 | 1000±10 | 900±10 |

| Thickness of grinding wheel(mm) | 400±20 | 250±20 | 250±20 | 200±20 | 200±20 | 200±20 | 160±20 |

| Dia.of grinding pan (mm) | 2100±30 | 2000±30 | 2000±30 | 1800±20 | 1800±20 | 1800±20 | 1700±20 |

| Thickness of grinding pan (mm) | 200±10 | 170±10 | 150±10 | 90±10 | 90±10 | 90±10 | 80±10 |

| Width of grinding pan (mm) | 360 | 360 | 360 | 230-250 | 230-250 | 230-250 | 170-220 |

| Power (kw) | 30 | 15 | 15 | 7.5 | 5.5 | 5.5 | 3 |

| Rotary speed (r/min) | For extract gold: 10-13 other: 18-22 | ||||||

| Input size (mm) | < 30 | ||||||

| Capacity (t/day) | Gold 20 | Gold 20 | Gold 15 | Gold 10 | Gold 8 | Gold 5 | Gold 3 |

If you need further information,please fill in your questions and comments in the form below.

Representatives from Baichy machinery will be back to you within the hour,thanking you for your support to Baichy machinery