The spring insurance system is an overload protection device that provides "spring-type" iron release protection for foreign matter (iron blocks). Under normal use, the equipment has a trouble-free operation rate of more than 95%.

PYB spring cone crusher combines the former Soviet Union technology with the cone crusher of the 1980s international advanced technology. It is developed on the original basis. Its unique spring insurance system as an overload protection device can effectively deal with the situation of metal foreign matter passing through the crushing chamber and protect the machine from damage; the product material size is relatively uniform, in a cubic shape, and the wear of the working surface of the moving cone is also relatively uniform.

Compared with PYB-600, PYB-900 has greater crushing capacity and is suitable for handling medium-sized material crushing tasks; PYB-1200 is suitable for large mines and sand and gravel production lines and other occasions, with high production capacity and crushing efficiency. PYB-1750 and PYB-2200 are large equipment among cone crushers, suitable for occasions with extremely high requirements for crushing capacity.

PYB spring cone crusher adopts a continuous rotation design. The crushing and unloading process of materials is carried out alternately and continuously along the working surface, thereby improving production efficiency. It can easily handle ores and rocks of various hardnesses and meet the production needs of different industries; there is a parallel band with an equal gap between its moving cone and fixed cone. This design makes the particle size of the finished material more uniform.

The discharge particle size of the PYB spring cone crusher is an adjustable range, which depends on the model, cavity type, and adjustment during operation. Taking the PYB1200 model as an example, its discharge particle size is roughly between 20-50mm. However, different models and configurations of PYB spring cone crushers may have different discharge particle size ranges.

• Ore crushing: PYB spring cone crusher is widely used in the metallurgical industry to crush various ores, such as iron ore, copper ore, etc. Its powerful crushing force and high crushing efficiency can meet the metallurgical industry's demand for raw material crushing.

• Construction aggregate production: PYB spring cone crusher can be used to produce construction aggregates, such as crushing limestone, granite, and other rocks to meet the construction industry's demand for aggregates.

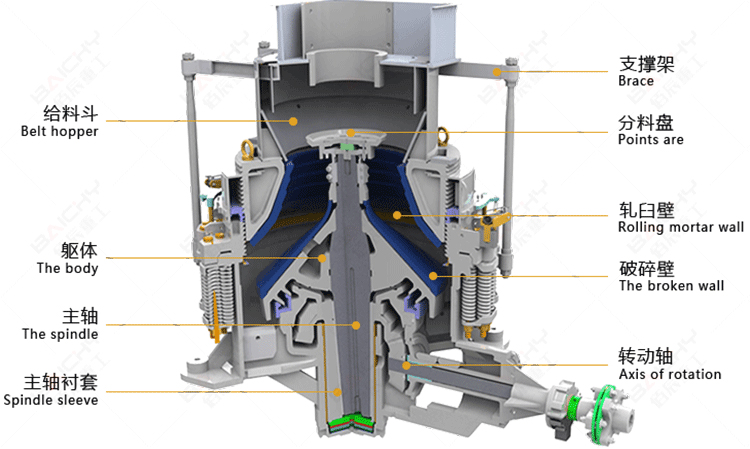

The PYB spring cone crusher is mainly composed of a frame, a transmission device, an empty eccentric shaft, a bowl-shaped bearing, a crushing cone (moving cone), an adjustment device, an adjustment sleeve, a spring, and a hydraulic station for adjusting the discharge port. Among them, the moving cone is supported on a spherical bearing and fixed on a suspended vertical shaft, which is placed in an eccentric sleeve, and the eccentric sleeve is placed on a thrust bearing.

• The swinging motion of the moving cone causes the gap between it and the fixed cone to move closer and farther from time to time.

• When the moving cone approaches the fixed cone, the gap between the two is reduced, which produces extrusion, shearing, and impact effects on the material, thereby achieving material crushing.

• The crushed material is discharged through the discharge port under the action of gravity and crushing force, completing the entire crushing process.

| Model |

Cone Diameter (mm) |

Max. Feed Size (mm) |

Outlet Setting Size (mm) |

Capacity (t/h) |

Power (kw) |

Overall Dimension (mm) |

| PYB-600 | 600 | 66 | 12-25 | 15-25 | 30 | 1740X1225X1940 |

| PYD-600 | 600 | 36 | 3-13 | 5-23 | 30 | 1740X1225X1940 |

| PYB-900 | 900 | 115 | 15-50 | 50-90 | 55 | 1990X1640X2380 |

| PYZ-900 | 900 | 60 | 5-20 | 20-65 | 55 | 1990X1640X2380 |

| PYD-900 | 900 | 40 | 3-13 | 15-50 | 55 | 1990X1640X2380 |

| PYB-1200 | 1200 | 145 | 20-50 | 110-200 | 110 | 2805X2300X2980 |

| PYZ-1200 | 1200 | 100 | 8-26 | 50-150 | 110 | 2805X2300X2980 |

| PYD-1200 | 1200 | 50 | 3-15 | 18-105 | 110 | 2805X2300X2980 |

| PYB-1750 | 1750 | 215 | 25-60 | 280-480 | 155-160 | 3610X2950X4185 |

| PYZ-1750 | 1750 | 185 | 10-30 | 115-230 | 155-160 | 3610X2950X4185 |

| PYD-1750 | 1750 | 85 | 5-15 | 75-230 | 155-160 | 3610X2950X4185 |

| PYB-2200 | 2200 | 300 | 30-60 | 590-1000 | 260-280 | 4790X3430X5080 |

| PYZ-2200 | 2200 | 230 | 10-30 | 200-580 | 260-280 | 4790X3430X5080 |

| PYD-2200 | 2200 | 110 | 5-16 | 120-370 | 260-280 | 4790X3430X5080 |

Have Any Questions!

Don't Hesitate To Contact Us AnyTime.

If you need further information,please fill in your questions and comments in the form below.

Representatives from Baichy machinery will be back to you within the hour,thanking you for your support to Baichy machinery