MTW trapezoidal European version mill is designed by professional R&D engineers with great concentration on research and innovation based on the absorption of new European grinding technology and concepts, combined with long-term mill R&D experience, and integrated with a large number of customer feedback and suggestions. It is an upgraded product of the traditional Raymond mill, with mature technology and powerful functions. It is widely used in power, mining, metallurgy, chemical industry, steel, building materials, coal, and other industries, and has produced huge economic and social benefits.

MTW110 is suitable for small and medium-sized production lines, with moderate processing capacity, suitable for occasions where the output requirements are not very high; MTW138 has improved processing capacity compared to MTW110T, suitable for medium-sized production lines; MTW175 has further enhanced processing capacity, suitable for large production lines, and can efficiently complete the grinding of a large number of materials; as an upgraded product of the traditional Raymond mill, it has the advantages of high efficiency, energy saving and environmental protection, durability and easy maintenance.

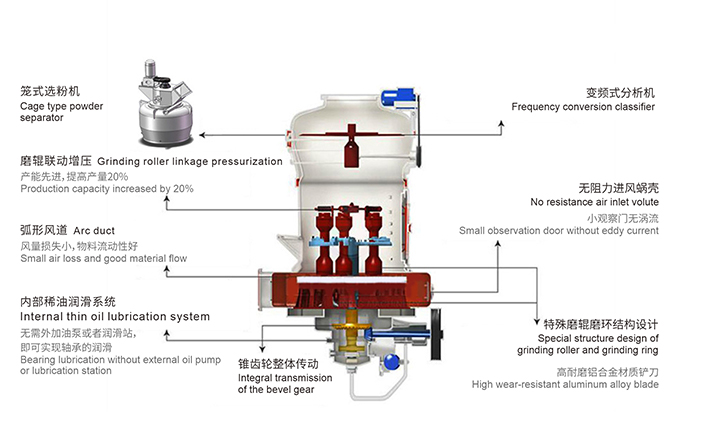

Stable velocity field, high powder selection accuracy, high efficiency, and accurate cutting particle size.

The inner surface of the internal door panel and the inner surface of the air inlet volute are on the same curved surface, which effectively avoids the eddy current effect and reduces energy consumption.

The grinding roller and grinding ring are made of high-quality materials with good wear resistance and a long replacement cycle, which reduces maintenance costs.

The speed of the analyzer is controlled by frequency conversion, and the fine material separation effect is better.

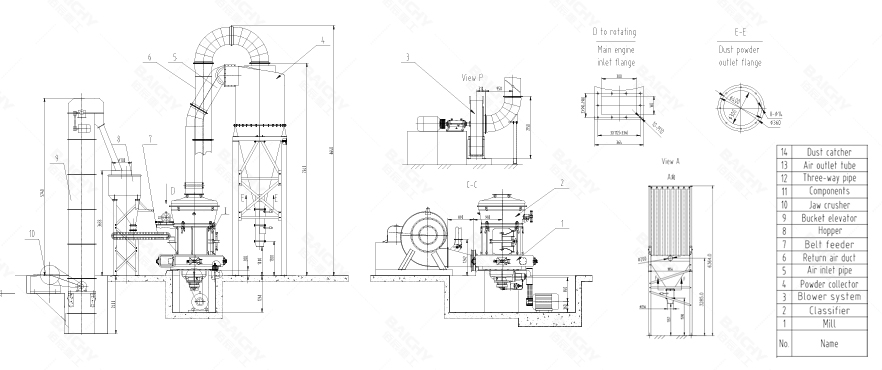

1. Material crushing and transportation: Large pieces of material are first crushed to the required particle size by the jaw crusher, and then the materials are sent to the storage hopper by the elevator. Then, the materials are uniformly and quantitatively continuously fed into the main milling chamber through the vibrating feeder for grinding.

2. Grinding process: In the main grinding chamber, the material is subject to the combined action of the grinding roller and the grinding ring. The grinding roller device not only rotates around the central axis but also revolves around the grinding ring. At the same time, the grinding roller itself rotates due to friction. This movement mode causes the material to be strongly impacted and ground between the grinding roller and the grinding ring, thereby being crushed into fine powder.

| Model | Roller Size (mm) | Grind Ring Size DxH(mm) | Main Roller Speed (r/min) | Max Feeding Size (mm) | Output Size (mm) | Capacity (t/h) | Power (Kw) | Overall Dimension (mm) |

| MTW110 | 360×210 | 1100×210 | 120 | 30 | 0.038-1.6 | 4-12 | 55 | 8910×6950×9010 |

| MTW138 | 460×260 | 1380×260 | 96 | 35 | 0.038-1.6 | 8-20 | 110 | 9860×8340×10227 |

| MTW175 | 520×300 | 1750×300 | 75 | 40 | 0.038-1.6 | 20-35 | 200 | 13500×11500×9500 |

| MTW215 | 640×340 | 2150×340 | 65 | 50 | 0.038-1.6 | 30-50 | 280 | 13922×9810×13226 |

If you need further information,please fill in your questions and comments in the form below.

Representatives from Baichy machinery will be back to you within the hour,thanking you for your support to Baichy machinery