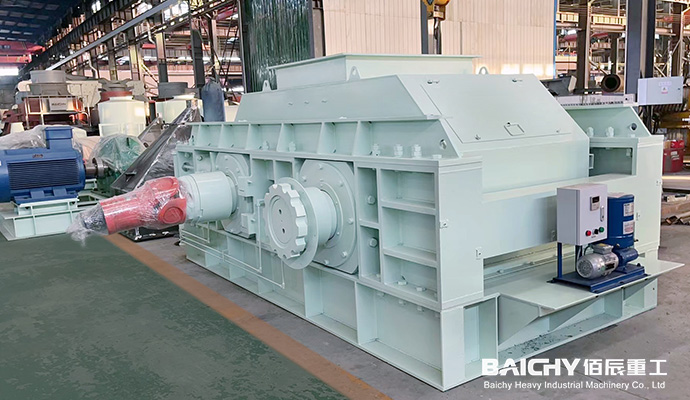

The double-roller crusher has significant advantages in the crushing industry, and these advantages make it an ideal choice in a variety of application scenarios.

Double roll crusher is suitable for crushing a variety of materials, including ore, coal, construction waste, refractory materials, chemical raw materials, etc., and is used for coarse and medium crushing of brittle block materials.

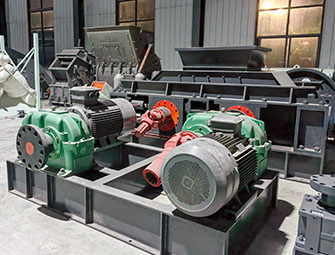

Smooth Roll Crusher

double roller crusher

roller crusher

stone crusher

The roller crusher has a compact structure, small footprint, and a high crushing ratio, which can meet the crushing requirements of different particle sizes; it has a small size, a large crushing ratio, easy maintenance, safety and reliability, and adjustable discharge particle size.

Ore crushing: Roller crushers are used in mining to crush ores of various hardnesses, such as limestone, granite, iron ore, etc. Whether it is an open-pit mine or an underground mine, roll crushers can perform crushing operations well to meet the needs of mining production.

Slag processing: In the metallurgical and chemical industries, roll crushers are often used to crush various slags and chemical raw materials into the required particle size for subsequent smelting or processing.

The double-roll crusher performs crushing operations through rollers. The material enters between the rollers from the feed port and is crushed by extrusion. When the roller seats rotate towards each other, the material is rolled between the two rollers under the action of the friction force on the roller surface and its own gravity and is subjected to extrusion, impact, shearing, and kneading from the rollers. When the action of these forces is greater than the aggregation force between the crystal lattices of the object, the material breaks into small pieces and the purpose of crushing is achieved.

| Model | Roller Diameter (mm) |

Roller Length (mm) |

Feeding Size (mm) |

Capacity (t/h) |

Motor Power (kw) |

| 2PG-400X250 | 400 | 250 | ≤ 25 | 2-10 | 2*5.5 |

| 2PG-610X400 | 610 | 400 | ≤ 30 | 5-20 | 2*15 |

| 2PG-610X750 | 610 | 750 | ≤ 30 | 5-25 | 2*18.5 |

| 2PG-750X400 | 750 | 400 | ≤ 30 | 10-40 | 2*18.5 |

| 2PG-800X600 | 800 | 600 | ≤ 40 | 12-50 | 2*22 |

| 2PG-800X800 | 800 | 800 | ≤ 40 | 20-60 | 2*22 |

| 2PG-900X900 | 900 | 900 | ≤ 50 | 50-100 | 2*37 |

| 2PG-1200X900 | 1200 | 900 | ≤ 50 | 60-130 | 2*45 |

| 2PG-1200X1200 | 1200 | 1200 | ≤ 50 | 80-150 | 2*45 |

Have Any Questions!

Don't Hesitate To Contact Us AnyTime.

If you need further information,please fill in your questions and comments in the form below.

Representatives from Baichy machinery will be back to you within the hour,thanking you for your support to Baichy machinery