PF series impact crusher has a compact structure, and large crushing ratio, and adopts multi-cavity uniform crushing technology, which is suitable for crushing hard rock and has a better crushing effect.

PF series impact crusher is a mechanical equipment that uses the high-speed impact principle for crushing. It is mainly used for medium and fine crushing of various medium-hard materials with compressive strength not higher than 100MPa, such as limestone, clinker, slag, coke, coal, etc.

PF series impact crusher has a variety of models to choose from. Different models of crushers have differences in rotor size, processing capacity, power consumption, etc. It is an efficient, energy-saving, and durable crushing equipment.

PFW-1315, PF-1214, and PF-1210 impact crushers perform well in processing medium-hard materials, with high crushing efficiency and large crushing ratio. The product shape is mostly cubic, with the advantage of selective crushing, and the discharge particle size is adjustable, simplifying the process.

PF-1010 and PF-1007 may have slightly lower processing capacity, but users still favor their compact structure, flexible layout, and low investment cost in some occasions where the output requirements are not particularly high.

Multi-cavity uniform crushing: suitable for crushing hard rock and other materials with high compressive strength, with a uniform crushing effect.

Low and large feed port: convenient for production line layout and increasing feed size, improving production efficiency.

Fully hydraulic opening: convenient for repair and replacement of wearing parts, reducing maintenance costs.

New wear-resistant materials: key components such as hammer, impact liner, and liner are made of new wear-resistant materials, with longer service life.

The discharge range of the PF series impact crusher is affected by many factors, including equipment model, rotor size, feed size, hardness, purity, and moisture content of crushed materials.

1. Rotor speed is one of the important factors affecting the discharge size.

2. The gap between the impact plate and the hammer will also directly affect the discharge size.

3. The aperture size of the screen plate is also an important factor affecting the discharge size.

PF series impact crusher is mainly used for medium and fine crushing of various medium hardness materials and is widely used in metallurgy, mining, chemical industry, building materials, highways, railways, water conservancy, and other industries. Especially when producing stones for high-speed highways, hydropower, construction, and other industries, the equipment performs well.

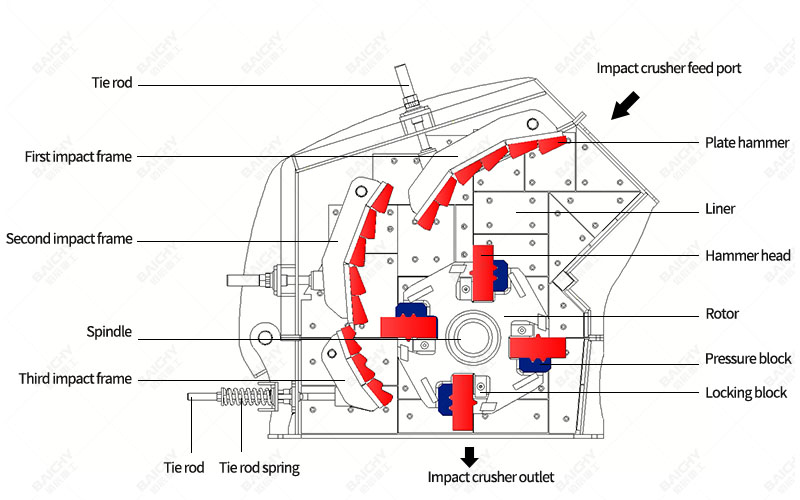

The crushed material blocks fly to the impact plate at a faster rate along the tangent direction and are further crushed by the impact again. In this way, the material is repeatedly impacted and crushed in the crushing chamber formed by the plate hammer and the impact plate until its particle size is smaller than the gap between the impact plate and the plate hammer, and finally discharged from the discharge port.

| Model |

Feeder opening size(mm) |

Max feeding size(mm) |

Rotor size D*L(mm) |

Capacity (t/h) |

Power (kw) |

Overall Dimension (mm) |

| PF1007 | 450X730 | ≤250 | Φ1000X700 | 15-60 | 45 | 2330x1700x2560 |

| PF1010 | 400X1080 | ≤300 | Φ1000X1050 | 50-90 | 55 | 2330x2010x2560 |

| PF1210 | 450X1150 | ≤400 | Φ1250X1050 | 70-130 | 90 | 2640x2010x2850 |

| PFW1210 | 450X1150 | ≤400 | Φ1250X1050 | 75-140 | 90 | 2900x2000x2600 |

| PFW1214 | 480x1500 | ≤430 | Φ1250X1400 | 100-180 | 132 | 2900x2400x2600 |

| PFW1315 | 860X1520 | ≤500 | Φ1320X1500 | 130-220 | 200 | 3300x2650x2650 |

| PFW1320 | 900X2000 | ≤500 | Φ1320X2000 | 160-350 | 250 | 3350x3175x2720 |

| PFW1515 | 930x1550 | ≤600 | Φ1500X1500 | 200-400 | 280 | 3450x2750x3010 |

| PFW1520 | 930X2040 | ≤700 | Φ1512X2000 | 300-450 | 355 | 3450x3250x3010 |

| PFW1820 | 1620X2040 | ≤700 | Φ1800X2000 | 500-800 | 2 x 315 | 4400x3750x3900 |

Have Any Questions!

Don't Hesitate To Contact Us AnyTime.

If you need further information,please fill in your questions and comments in the form below.

Representatives from Baichy machinery will be back to you within the hour,thanking you for your support to Baichy machinery