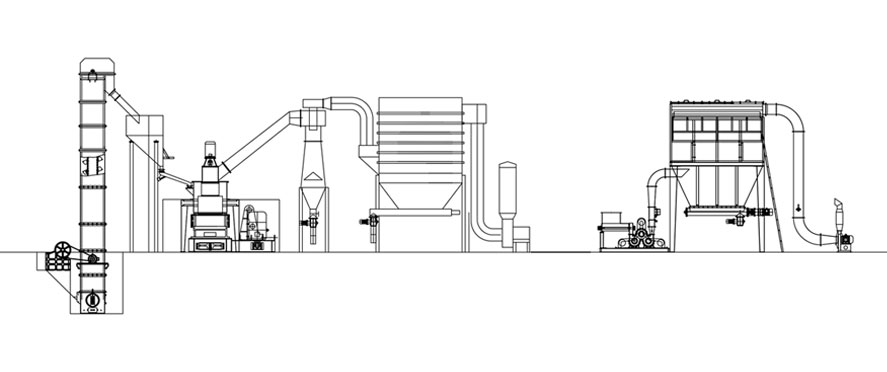

YGM high-pressure roller mill uses the principle of static pressure crushing to efficiently and finely crush materials. It is an efficient and energy-saving crushing equipment, widely used in mining, building materials, the chemical industry, metallurgy, and other industries.

YGM high-pressure roller mill can process a wide range of materials, including but not limited to quartz, feldspar, barite, fluorite, dolomite, garnet, silicon carbide, bauxite, zircon sand, marble, calcite, iron ore, phosphate rock, etc., with a Mohs hardness of no more than 9.3 and a humidity of less than 6%, more than 400 kinds of non-flammable and explosive materials.

YGM85, YGM95, and YGM130 are all hot-selling models of YGM high-pressure roller mills; these models have their characteristics in terms of processing capacity, crushing fineness, energy consumption, etc., and users can choose according to their own needs.

YGM85 has high crushing efficiency and stable performance; YGM95 high-pressure Raymond mill is also a hot-selling model, which is suitable for occasions such as 200-mesh petroleum coke pulverizing production lines, with stable performance and reliable quality; YGM130 high-pressure suspension roller mill is a model with superior performance, which can handle larger batches of materials, and the finished product particle size is adjustable to meet different production needs.

YGM high-pressure roller mill adopts advanced crushing principle and structural design, with the advantages of large processing capacity, high crushing efficiency, and low energy consumption.

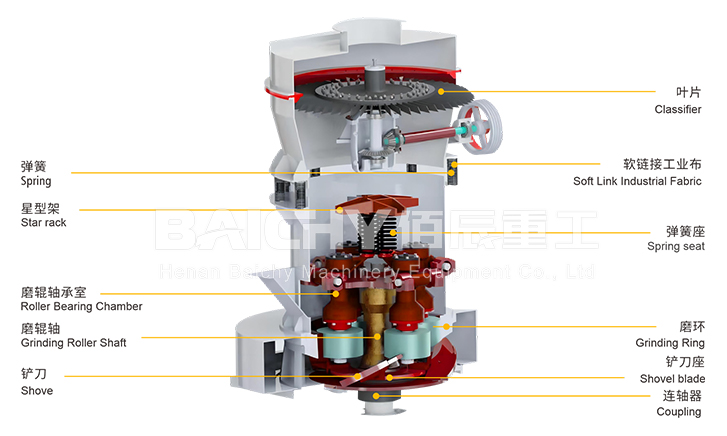

By adjusting the speed of the analyzer and the gap between the grinding roller and the grinding ring, the finished product particle size can be easily adjusted to meet different production needs.

The grinding roller and grinding ring are made of high-quality materials with good wear resistance and a long replacement cycle, which reduces maintenance costs.

The equipment generates less dust during operation, and the dust collector can effectively purify the exhaust gas and protect the production environment.

The working principle of the YGM mill is similar to that of the Raymond mill, but the grinding device is equipped with a high-pressure spring with a pressure of 1000-1500 kg. When the grinding mill starts working, the grinding roller rotates around the main axis and rolls close to the grinding ring under the action of high-pressure spring and centrifugal force. Its rolling pressure is 20% higher than other equipment under the same conditions, so the output is greatly improved. improve.

The working principle of the YGM high-pressure roller mill is that the motor drives the main shaft to rotate, and the main shaft drives the grinding roller to make a circular motion around the grinding ring. After the material enters the equipment from the feed port, it is squeezed, ground, and sheared by the grinding roller and the grinding ring, and is crushed into the required particle size. The ground materials are separated by a classification system to obtain qualified finished materials.

| Model | Roller No. | Roller Size (mm) | Grind Ring Inner Dia. Height & Length(mm) | Feeding Size (mm) | Output Size (mm) | Capacity (t/h) | Power (Kw) | Overall Dimension (mm) |

| YGM65 | 3 | 210×150 | 650×150 | ≤ 15 | 0.613-0.033 | 0.4-1.8 | 15 | 4100×3300×4500 |

| YGM75 | 3 | 260×150 | 780×150 | ≤ 15 | 0.613-0.033 | 1-3 | 18.5 | 4300×3500×5100 |

| YGM85 | 3 | 270×150 | 830×150 | ≤ 20 | 0.613-0.033 | 1.2-4 | 22 | 5300×4100×5200 |

| YGM85B | 3 | 270×150 | 830×150 | ≤ 20 | 0.613-0.03 | 1.2-3.5 | 22 | 5300×4100×5200 |

| YGM95 | 4 | 310×190 | 950×190 | ≤ 25 | 0.613-0.033 | 2.1-5.6 | 45 | 7100×5900×7900 |

| YGM130 | 5 | 410×230 | 1280×230 | ≤ 30 | 0.613-0.033 | 2.5-9.5 | 90 | 7900×8000×9700 |

| YGM160 | 6 | 450×300 | 1600×300 | ≤ 35 | 0.613-0.033 | 8-16 | 132 | 12550×5700×8355 |

| YGM190 | 6 | 500×330 | 1900×330 | ≤ 40 | 0.613-0.033 | 18-36 | 250 | 11200x8530x9685 |

If you need further information,please fill in your questions and comments in the form below.

Representatives from Baichy machinery will be back to you within the hour,thanking you for your support to Baichy machinery