Dry ball mill is a kind of high-efficiency grinding equipment widely used in mining, building materials, the chemical industry, and other industries. It is mainly used for dry grinding of various ores, cement clinker, coal powder, and other materials. Unlike a wet ball mill, a dry ball mill does not need to add water, which is suitable for materials sensitive to moisture or processes that need to obtain dry powder directly.

1. Metal ores

• Iron ore, gold ore, copper ore, lead-zinc ore, etc. are used for pre-crushing before ore dressing to make the ore reach a particle size suitable for sorting.

• Dry grinding of rare metal ores such as tungsten ore, molybdenum ore, and manganese ore to avoid moisture affecting subsequent flotation or smelting.

2. Non-metallic minerals

• Quartz sand, feldspar, kaolin, talc, ceramics, and glass raw materials preparation, the materials need to be kept dry.

• Limestone, calcite, and barite are used for ultra-fine powder processing of building materials, coatings, and plastic fillers.

• Graphite, fluorite, bentonite, refractory materials or chemical raw materials are dry ground.

3. Building materials and chemical raw materials

• Cement clinker, slag, fly ash, key grinding equipment in cement production, directly output dry powder.

• Processing of raw materials for gypsum, silica powder, mica building additives or fireproof materials.

• Dry grinding of coal powder, coke energy or fuel in the metallurgical industry.

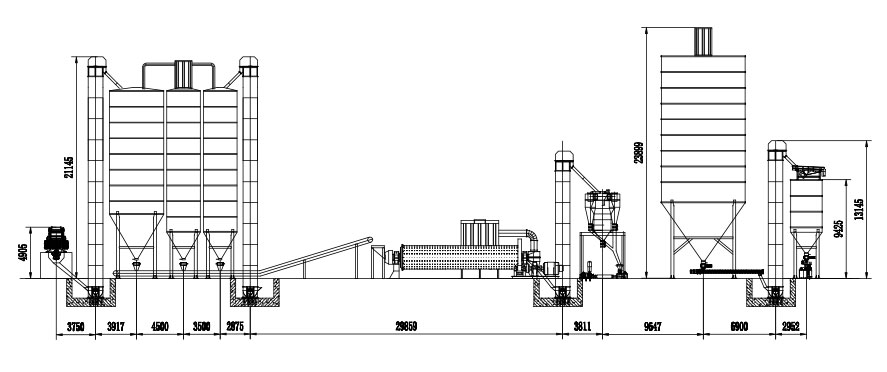

cement ball mill plant

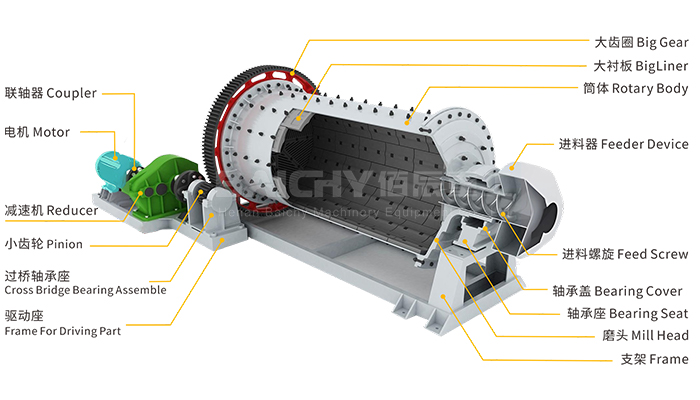

Mining Ball Mill

Inner wall lining

Ball mill steel balls

The choice between dry ball mill and wet ball mill mainly depends on the material characteristics and process requirements:

1. Dry ball mill is suitable for water-sensitive materials (such as cement, coal powder) or occasions where dry powder needs to be obtained directly. It has the advantages of low energy consumption and simple maintenance, but attention should be paid to dust control;

2.Wet ball mill is suitable for water-containing processes (such as mineral processing). It has higher grinding efficiency and can reduce dust, but subsequent wastewater treatment and high energy consumption are required. If the material is afraid of water or requires dry production, dry type is preferred; if wet sorting is required or the fineness requirement is extremely high, wet type is more suitable.

It is recommended to consider the material characteristics, environmental protection requirements and later costs comprehensively.

The optimized design and wear-resistant materials reduce energy consumption by 20%-30% compared with traditional crushing equipment, and the grinding efficiency is increased by more than 35%, which greatly reduces production costs.

It can process various ores, chemical raw materials, and solid waste (such as steel slag, fly ash) with Mohs hardness ≤9; it supports dry grinding and wet grinding to meet the fineness requirements of different industries (80-2500 mesh adjustable).

The core components have a long life, the high manganese steel liner has a service life of 5-8 years, and the gear transmission system adopts carburizing and quenching technology, with a failure rate of <1%.

By adjusting the grinding medium (steel ball/ceramic ball) ratio, the cylinder speed (0.5- 40 rpm), and the grading system, the finished product fineness error can be controlled within ±2μm.

The working principle of ball mill grinding is to achieve material crushing and grinding through strong collision and friction between the rotating grinding drum and the internal grinding media. In this process, the particle size of the material gradually decreases to achieve the required fineness and uniformity.

1. Initial stage: the number of grinding balls is small, the particles in the material are large, and the grinding balls have little wear on the material.

2. Stable stage: with the increase of running time, the number of grinding balls gradually increases, the particles in the material gradually become smaller, the grinding balls gradually increase the wear on the material, and the material is gradually ground.

| Model | Capacity(t/h) | Rotate speed(r/min) | Grinding Balls(t) | Motor Power(kw) | Gear box | |

|---|---|---|---|---|---|---|

| Model | Speed Ratio | |||||

| Ф1.2x4.5 | 1.6-5.8 | 30.3 | 5 | 55 | ZD30 | 4.5 |

| Ф1.5x5.7 | 3.5-6 | 26.34 | 11 | 130 | ZD40 | 4 |

| Ф1.83x6.4 | 6.5-15 | 23.9 | 21 | 210 | ZD60 | 4.5 |

| Ф1.83x7 | 7.5-17 | 24.5 | 23 | 245 | ZD60 | 4.5 |

| Ф2.2x6.5 | 14-20 | 21.4 | 31 | 280 | ZD70 | 5 |

| Ф2.4x7 | 17-28 | 20.4 | 39 | 380 | ZD80 | 5 |

| Ф2.4x8 | 20-35 | 20.3 | 42 | 570 | ZD80 | 5 |

| Ф2.4x12 | 35-45 | 20 | 63 | 800 | MBY710 | 6.3 |

| Ф2.4x13 | 35-38 | 19.4 | 68 | 800 | MBY710 | 6.3 |

| Ф2.6x13 | 40-55 | 19.5 | 82 | 1000 | JDX800 | 6.3 |

| Ф3x9 | 50-55 | 18.34 | 78 | 1000 | JDX800 | 6.3 |

| Ф3.2x9 | 60-70 | 17.6 | 95 | 1250 | MBY900 | 7.1 |

| Ф3.5x11 | 75-85 | 16.8 | 150 | 1250 | JDX900 | 5.84 |

| Ф3.8x12 | 85-110 | 17 | 175 | 1600 | MBY800 | 5.6 |

| Ф4.6x10+3.5 | 180-210 | 15 | 278 | 3550 | JQS3500 | 15.1 |

Wet method: Suitable for subsequent flotation processes or scenes that require dust prevention (such as gold mines and copper mines), with low energy consumption but requiring wastewater treatment.

Dry method: Suitable for industries that do not require liquids, such as building materials and chemicals, but requires a dust removal system.

Steel balls: High density and strong impact force, suitable for hard materials such as metal ores, but may introduce iron impurities.

Ceramic balls: Pollution-free and corrosion-resistant, suitable for fields with high purity requirements (such as electronic-grade silicon powder), with a high cost.

Capacity (t/h) = 0.2×Cylinder effective volume (m³)×Filling rate (25%-45%)×Material density

▶ For example: When a Φ2.4×6m ball mill wet grinds iron ore, the theoretical capacity is about 8-12t/h.

Optimize the steel ball grading: large balls (Φ100mm) account for 40% + small balls (Φ20mm) account for 60% impact is more efficient.

Frequency control: adjust the speed according to the hardness of the material, saving 15%-20% energy.

Regular maintenance: replace the worn liner in time to avoid ineffective power consumption.

If you need further information,please fill in your questions and comments in the form below.

Representatives from Baichy machinery will be back to you within the hour,thanking you for your support to Baichy machinery