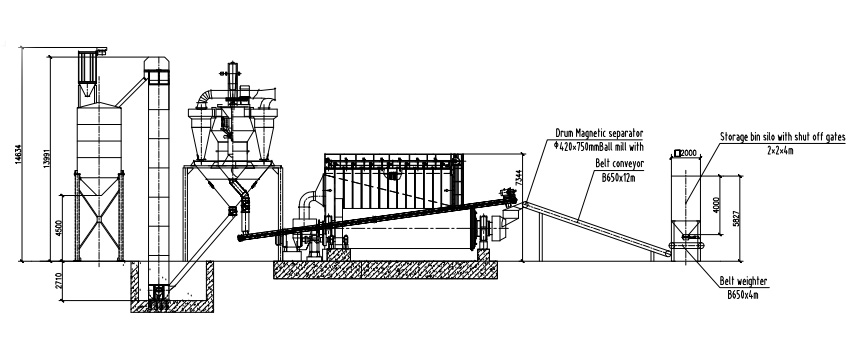

The powder classifier is often used in conjunction with the Raymond mill or ball mill to form a complete grinding production line, which is widely used in cement production, fly ash production, gypsum grinding, etc.

The powder classifier is mainly used for the classification of raw meal, clinker, heavy calcium, kaolin, talc powder, barite powder, mica, graphite, aluminum hydroxide, etc., and can obtain ultra-fine powders of more than 300 mesh.

Particle size distribution is more reasonable, final product quality has been improved significantly.

The energy produced by the rotation of the airflow is transmitted to the rotor, thus reducing the electricity consumption of the drive device and avoiding the energy consumption of the slipstream.

Our company's high-efficiency powder classifier is based on the traditional powder classifier and adopts advanced technology to continuously upgrade. It can make the material separation rate higher and the powder selection effect better.

This powder classifier has a reasonable structure and reliable quality, and the wear-resistant parts are made of high-quality steel, which will not be easily damaged, so you can use it with confidence.

The finished fineness of the powder classifier can be controlled by adjusting the wind speed according to the demand, and the adjustment is convenient and reliable.

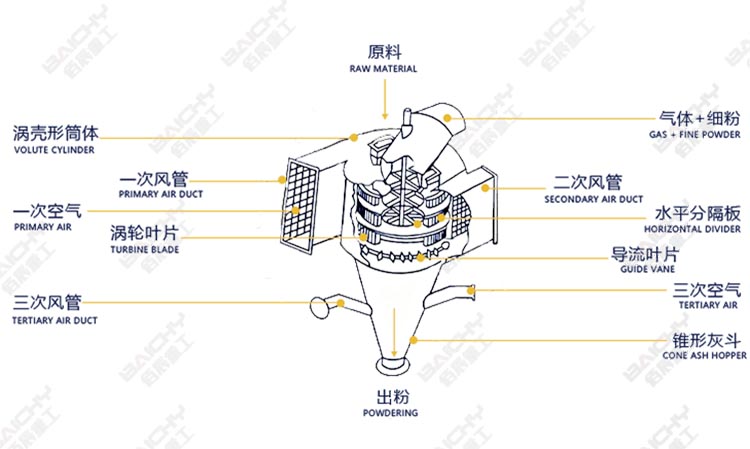

The upper part of the powder classifier is a cylindrical grading chamber, and the lower part is a conical discharge port. Usually, two or more powder classifiers form a powder classifying system.

The ground powder is fed from the upper part of the powder classifier, and after being fully dispersed by the spreading plate and the baffle plate, the coarse powder is discharged through the coarse powder pipe, and the fine powder that meets the requirements enters the high-efficiency and low-resistance cyclone separator with the circulating air and slides Into the fine powder collection cone to become a finished product.

| Model | S400 | S500 | S600 | S700 | S900 | S1000 | S1100 | S1200 | |

| Matched mill (m) | Φ1.5 | Φ1.83 | Φ2.2 | Φ2.4 | Φ3.0 | ||||

| Motor Blower | Model | YCTL200-4A | YCTL200-4B | YCTL200-4A | YCTL200-4B | YCTL200-4B | YCTL200-4A | YCTL200-4A | YCTL200-4B |

| Rotating speed(r/min) | 125-1250 | 132-1320 | 440-1340 | 440-1340 | 600-1340 | ||||

| Power (KW) | 7.5 | 11 | 15 | 18.5 | 37 | 55 | 75 | 90 | |

| Model | SCF-12NO.8C | SCF-12NO.8C | SCF-12NO.10C | SCF-12NO.12C | SCF-12NO.12C | SCF-12NO.16B | SCF-12NO.16D | SCF-12NO.12C | |

| Volume | 24216 | 30900 | 37960 | 58200 | 119332 | 168000 | 192000 | 211000 | |

| Air pressure | 2.18 | 2.43 | 2.34 | 2.07 | 2.26 | 2.70 | 2.70 | 2.60 | |

| Rotating speed(r/min) | 1500 | 1600 | 1200 | 1000 | 800 | 960 | 960 | 710 | |

| Model | Y180M-2 | Y200L1-2 | Y225S-4 | Y225M-4 | Y335M1-8 | Y335M1-6 | Y335M3-6 | Y335L-8 | |

| Power (KW) | 22 | 30 | 37 | 55 | 132 | 160 | 200 | 220 | |

| Rotating speed of shaft (r/min) | 190-380 | 190-380 | 150-350 | 150-350 | 140-350 | 100-300 | |||

If you need further information,please fill in your questions and comments in the form below.

Representatives from Baichy machinery will be back to you within the hour,thanking you for your support to Baichy machinery