The wheel-type sand washing machine has the characteristics of high cleaning height, reasonable structure, large output, and less sand loss during the sand washing process of the sand washing machine. It is an ideal choice for upgrading the domestic sand washing industry.

Wheel sand washer is a mechanical device specially used for cleaning sand and gravel. It mainly removes dirt, dust, and other impurities in sand and gravel through the combined action of mechanical force (such as impeller rotation) and water flow, thereby improving the cleanliness and quality of sand and gravel.

sand washer, wheel sand washing machine, bucket wheel sand washer machine

sand washer, wheel sand washing machine, bucket wheel sand washer machine

sand washer, wheel sand washing machine, bucket wheel sand washer machine

sand washer, wheel sand washing machine, bucket wheel sand washer machine

The wheel sand washer also has certain environmental protection performance. During the cleaning process, it can effectively reduce the emission of dust and wastewater and reduce pollution to the environment. At the same time, through reasonable equipment design and operation management, it can also realize the recycling of water resources and improve resource utilization efficiency.

Bucket wheel sand washing machine is widely used in washing, grading, impurity removal, and other operations in metallurgy, building materials, hydropower, and other industries, especially suitable for washing fine and coarse-grained materials. It is especially suitable for construction sand and road construction gravel.

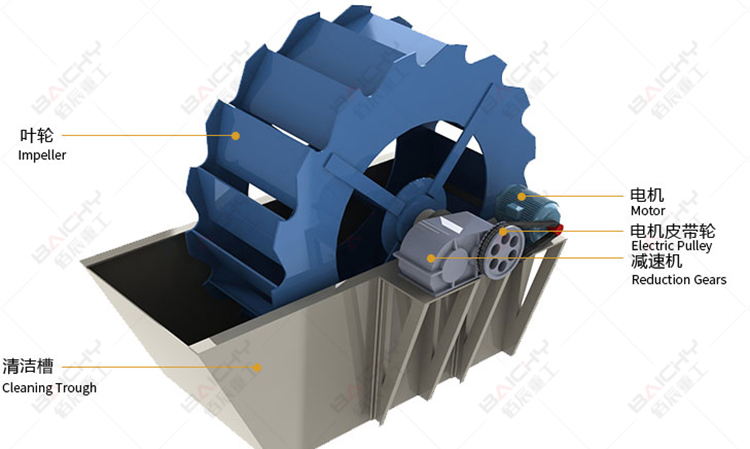

When the wheel-type sand washing machine is working, the motor drives the impeller to rotate slowly after being decelerated by the V-belt, the reducer, and the gear. At the same time, add water to form a strong water flow, take away impurities and foreign matter with a small specific gravity in time, and discharge them from the washing tank at the overflow port to complete the cleaning function. The clean gravel is taken away by the blades and poured into the discharge chute from the rotating impeller to complete the cleaning of the gravel.

| Model | Impeller Dia.(mm) | Feeding Size(mm) | Capacity(t/h) | Motor Power(kw) |

| XSD2300 | Φ2300 | ≤ 10 | 20-30 | 4 |

| XSD2610 | Φ2600 | 30-80 | 7.5 | |

| XSD2915 | Φ2900 | 60-120 | 11 | |

| XSD3016 | Φ3000 | 80-160 | 15 | |

| XSD3218 | Φ3200 | 130-220 | 22 | |

| XSD3420 | Φ3400 | 160-300 | 22-30 |

Have Any Questions!

Don't Hesitate To Contact Us AnyTime.

If you need further information,please fill in your questions and comments in the form below.

Representatives from Baichy machinery will be back to you within the hour,thanking you for your support to Baichy machinery