The mobile jaw crushing station has become one of the important pieces of equipment in the current field of rock crushing due to its high flexibility, integrated design, high efficiency and output, strong adaptability, environmental protection and energy saving, and reduced operating costs.

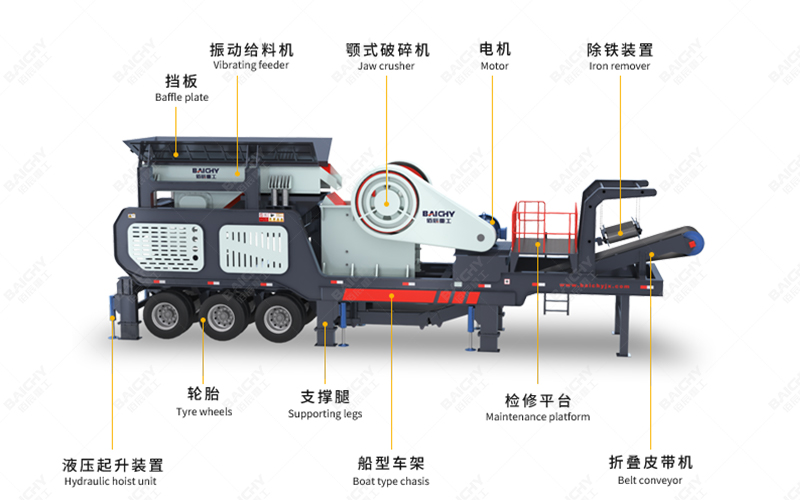

Mobile jaw crusher, also known as mobile coarse crusher or mobile stone crusher, is an advanced rock crushing equipment consisting of three systems feeding, crushing, and conveying. It adopts an integrated operation mode and can be easily moved to a suitable location for operation.

As an advanced rock stone crushing equipment, the mobile jaw crusher has a wide range of material applicability; it is suitable for processing a variety of materials including hard rocks, granite, limestone, basalt, Andesite, Diabase, river pebbles, ores and tailings, construction waste, etc.

When the mobile jaw crusher is used as coarse crushing equipment, it can be used in combination with various types of mobile crushers to form a complete stone crushing production line; such as mobile cone crusher, mobile impact crusher, mobile sand making plant, and mobile screening plant.

The mobile jaw crusher has the advantages of flexibility and convenience, efficient crushing capacity, environmental protection and energy saving, adaptability and flexibility, intelligence, and automation. In addition, stones with high hardness and wear resistance are particularly suitable for crushing by jaw mobile stations.

The mobile jaw crusher is mainly composed of a jaw crusher, a feeder, a vibrating screen, a belt conveyor, etc., all of which are installed on an independent movable chassis. The main equipment jaw crusher is composed of a fixed jaw plate and a movable jaw plate, and the space between the two forms a crushing chamber.

The material is evenly transported to the crusher through the feeder and enters the crushing chamber; the movable jaw plate is connected to the drive device through an eccentric shaft so that it can move up and down. When the movable jaw plate moves downward, the material is squeezed by the fixed jaw plate and the movable jaw plate, and gradually crushed into smaller particles.

The mobile jaw crusher can crush the material on the first line, eliminating the intermediate link of transporting the material away from the site and then crushing it, greatly reducing the transportation cost of the material.

| Model | SMC600 | SMC750 | SMC900 | SMC1060 | SMC1200 | SMC1300PEX |

| Transport size | ||||||

| Length(mm) | 8600 | 9600 | 11097 | 13300 | 15800 | 9460 |

| Width(mm) | 2520 | 2520 | 3759 | 2900 | 2900 | 2743 |

| Height(mm) | 3770 | 3500 | 3500 | 4440 | 4500 | 3988 |

| Alex weight(kg) | 10121 | 14500 | 21380 | 38430 | 64000 | 14730 |

| King pin weight(kg) | 5118 | 7500 | 10890 | 19450 | 34000 | 10490 |

| Jaw crusher | ||||||

| Model | PE | PE | PE | PE | PE | PEX |

| Feed opening(mm) | 400X600 | 500X750 | 600X900 | 750X1060 | 900X1200 | 300X1300 |

| Discharging hole setting range(mm) | 40-100 | 50-100 | 65-180 | 80-180 | 95-225 | 20-90 |

| Capacity(t/h) | 15-60 | 40-110 | 90-180 | 110-380 | 220-450 | 30-105 |

| Feeder | ||||||

| Feed hopper volume | 3 | 4 | 7 | 10 | 10 | 3 |

| Hopper width | 2200 | 2500 | 3000 | 3000 | 3000 | 2200 |

| Model | ZSW6520 | ZSW8530 | ZSW9638 | ZSW1142 | ZSW1349 | ZSW8530 |

| Belt conveyor | ||||||

| Model | B650X6 | B800X7 | B1000X8 | B1000X11 | B1200X13 | B1000X7 |

Have Any Questions!

Don't Hesitate To Contact Us AnyTime.

If you need further information,please fill in your questions and comments in the form below.

Representatives from Baichy machinery will be back to you within the hour,thanking you for your support to Baichy machinery