Cement ball mill, also known as a cement mill for short, is an important grinding equipment, which is widely used in cement production and other industrial.

Cement ball mill is a mechanical equipment that crushes, grinds, and refines materials through grinding balls.

It is mainly used for grinding finished products and raw materials in cement plants and is also suitable for grinding various ores and other grindable materials in industrial and mining enterprises.

The finished product fineness of the cement ball mill is an important technical indicator, which directly affects the quality and use of cement products.

The finished product fineness of the cement ball mill can be adjusted according to different models, specifications, and production processes.

The finished product fineness of the cement ball mill can reach multiple levels, among which the finer level can reach about 325 mesh.

The cement ball mill is well designed, and the interaction between the internal grinding body and the material is large, allowing the material to be fully ground in a short time, greatly improving production efficiency.

Through a carefully designed grinding system and precise control parameters, the cement ball mill can ensure uniform particle size distribution of the discharged materials and meet the strict requirements for cement particle size in production.

The cement ball mill is not only suitable for cement production but also can be used for other materials that require fine grinding, such as mineral powder, fly ash, etc., with strong versatility and flexibility.

High-quality cement ball mills are made of wear-resistant and corrosion-resistant materials, giving the equipment a long service life. At the same time, its stable operating performance ensures the continuity and stability of production.

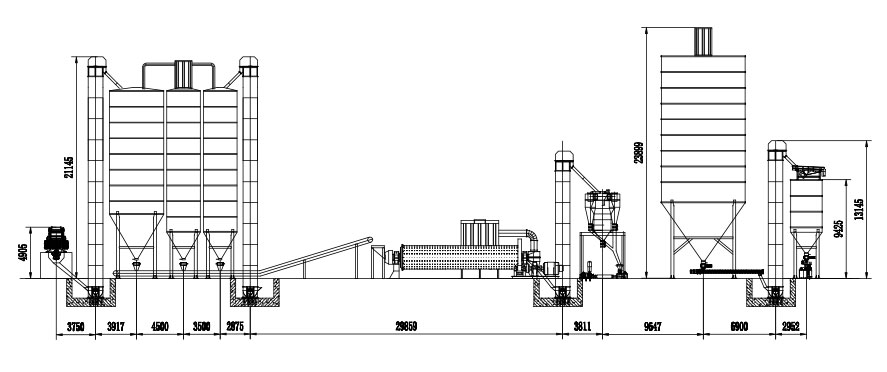

Limestone is more commonly used in the cement preparation process, but the mined limestone generally has larger particle sizes and needs to be crushed. Generally speaking, processing limestone into cement requires the preparation and homogenization of raw materials, the preparation of pulverized coal, the calcination of clinker, and the grinding of cement. stage.

1. Preparation and homogenization of raw meal: natural limestone, clay, and exotic raw materials are crushed by a jaw crusher and mixed in a certain proportion, and then ground by a ball mill to prepare raw meal with appropriate composition and uniform quality;

2. Pulverized coal preparation: The coal required for calcining cement raw materials must be prepared into pulverized coal to provide the particle size required for pulverized coal combustion to facilitate full combustion and obtain sufficient combustion reaction capacity. In this process, pulverized coal can be directly added, and equipment such as jaw crushers and ball mills will be used for processing.

3. Clinker calcination: Put the lime raw material in the rotary kiln and calcine it until it is partially melted to obtain lime clinker.

4. Cement grinding: that is, adding an appropriate amount of gypsum, mixed materials or additives to the clinker to grind it into cement, and then package it for shipment.

| Model | Capacity(t/h) | Rotate speed(r/min) | Grinding Balls(t) | Motor Power(kw) | Gear box | |

|---|---|---|---|---|---|---|

| Model | Speed Ratio | |||||

| Ф1.2x4.5 | 1.6-5.8 | 30.3 | 5 | 55 | ZD30 | 4.5 |

| Ф1.5x5.7 | 3.5-6 | 26.34 | 11 | 130 | ZD40 | 4 |

| Ф1.83x6.4 | 6.5-15 | 23.9 | 21 | 210 | ZD60 | 4.5 |

| Ф1.83x7 | 7.5-17 | 24.5 | 23 | 245 | ZD60 | 4.5 |

| Ф2.2x6.5 | 14-20 | 21.4 | 31 | 280 | ZD70 | 5 |

| Ф2.4x7 | 17-28 | 20.4 | 39 | 380 | ZD80 | 5 |

| Ф2.4x8 | 20-35 | 20.3 | 42 | 570 | ZD80 | 5 |

| Ф2.4x12 | 35-45 | 20 | 63 | 800 | MBY710 | 6.3 |

| Ф2.4x13 | 35-38 | 19.4 | 68 | 800 | MBY710 | 6.3 |

| Ф2.6x13 | 40-55 | 19.5 | 82 | 1000 | JDX800 | 6.3 |

| Ф3x9 | 50-55 | 18.34 | 78 | 1000 | JDX800 | 6.3 |

| Ф3.2x9 | 60-70 | 17.6 | 95 | 1250 | MBY900 | 7.1 |

| Ф3.5x11 | 75-85 | 16.8 | 150 | 1250 | JDX900 | 5.84 |

| Ф3.8x12 | 85-110 | 17 | 175 | 1600 | MBY800 | 5.6 |

| Ф4.6x10+3.5 | 180-210 | 15 | 278 | 3550 | JQS3500 | 15.1 |

If you need further information,please fill in your questions and comments in the form below.

Representatives from Baichy machinery will be back to you within the hour,thanking you for your support to Baichy machinery