PEX fine jaw crusher has been widely used and recognized in many industries for its advantages such as high-efficiency crushing capacity, adjustable finished product size, compact structure, simple maintenance, strong stability, long service life, wide application range, environmental protection, and energy saving.

PEX Series Fine Jaw Crusher is a common model of jaw crusher, specially designed for medium and fine crushing operations. It is suitable for secondary crushing of medium and high-hardness materials such as granite, basalt, iron ore, etc. It is a subdivided model of the PE jaw crusher series, with a deep cavity structure and adjustable discharge particle size (usually 10-60mm), which can efficiently complete fine crushing tasks.

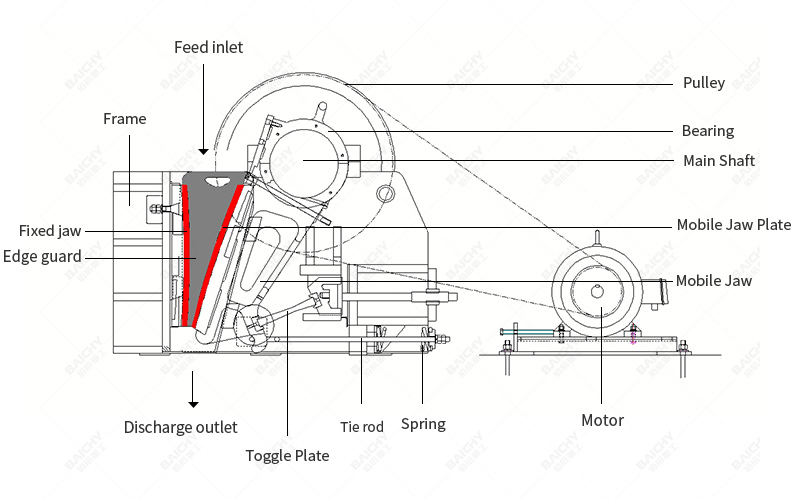

• Moving jaw motion trajectory: The design of "moving jaw suspension + eccentric shaft drive" is adopted, and the swing amplitude of the moving jaw is small at the top and large at the bottom, forming a "quasi-elliptical" motion trajectory to achieve efficient fine crushing.

• Crushing chamber type: Deep chamber design prolongs the material residence time and improves the fine crushing effect.

• Discharge port adjustment: Adjusted by gasket or hydraulic device, the discharge particle size is usually 10-60mm (depending on the model).

• Wear-resistant parts: High manganese steel jaw plate, impact and wear resistance.

PEX Fine Jaw Crusher

Primary Crushing Equipment

Mining Crusher Price

Small Jaw Crusher

• Efficient fine crushing: Compared with the PE coarse crushing model, PEX discharges finer materials and is suitable for secondary crushing.

• Low failure rate: simple structure, easy maintenance (such as a modular lubrication system).

• Energy saving: low unit energy consumption, more suitable for high hardness materials (such as granite, basalt) than an impact crusher.

• Small footprint: suitable for space-constrained links in the production line.

Difference between PEX and PE jaw crusher lies in the crushing stage, discharge particle size and structural design: PE is suitable for coarse crushing of bulk materials (large feed particle size, coarse discharge), while PEX specializes in medium and fine crushing (finer discharge, adjustable particle size).

When choosing, it is necessary to combine the material hardness, feed size, and finished product requirements to ensure that the equipment matches the production needs. In addition, correct operation and regular maintenance can greatly extend the service life of the jaw crusher.

PEX fine jaw crusher can be used for crushing various metal ores and non-metallic ores, such as iron ore, copper ore, gold ore, manganese ore, limestone, dolomite, etc. It can crush large pieces of ore into smaller particles, which is convenient for subsequent mineral processing, smelting, or processing.

PEX fine jaw crusher adopts the principle of curved extrusion crushing. Through the periodic reciprocating motion of the movable jaw, the material is squeezed, split, and broken, and finally the crushing effect is achieved.

Feeding stage: The material enters the crushing chamber from the feed port and falls between the movable jaw and the fixed jaw.

Extrusion crushing: The motor drives the eccentric shaft to rotate, driving the movable jaw to do reciprocating motion, and exerts pressure on the material when it is close to the fixed jaw to crush it.

Discharging stage: The crushed material moves downward under the action of gravity and is discharged after reaching the size of the discharge port.

Cyclic crushing: The material that does not meet the particle size requirements continues to be squeezed until it meets the discharge requirements.

Moving jaw motion trajectory: The optimized elliptical motion trajectory improves the crushing efficiency and reduces energy consumption.

High crushing ratio: Deep cavity design + fine crushing jaw plate, so that the material is crushed multiple times in the cavity, improving the fine crushing effect.

| Model |

Feeder Opening Size(mm) |

Max. Feeding Size (mm) |

Outlet adjusting Size(mm) |

Capacity (t/h) |

Motor Power (kw) |

Overall Dimension (mm) |

| PEX150x750 | 150x750 | 120 | 10-40 | 5-16 | 15 | 1310x1118x1145 |

| PEX250x750 | 250x750 | 210 | 15-50 | 15-30 | 22 | 1440x1751x1515 |

| PEX250x1000 | 250x1000 | 210 | 15-60 | 15-52 | 30 | 1730x1950x1400 |

| PEX250x1200 | 250x1200 | 210 | 15-60 | 25-80 | 37 | 1730x2150x1400 |

| PEX300x1300 | 300x1300 | 250 | 25-60 | 30-105 | 55 | 2000x2320x1730 |

Have Any Questions!

Don't Hesitate To Contact Us AnyTime.

If you need further information,please fill in your questions and comments in the form below.

Representatives from Baichy machinery will be back to you within the hour,thanking you for your support to Baichy machinery