The portable jaw crusher combines rough crushing and conveying equipment with high efficiency, flexibility, intelligent control, environmental protection, energy saving, cost reduction, strong adaptability, and strong continuous operation capability.

• The portable jaw crusher adopts a vehicle-mounted installation form and has good maneuverability. It can be easily moved to different working locations to meet the crushing needs of various complex environments.

• Equipment installation and removal is quick and easy, reducing downtime and transportation costs.

• The design of the portable jaw crusher pays attention to environmental protection and energy saving and adopts a low-noise and low-vibration design to reduce the impact on the environment.

• The equipment can efficiently utilize energy during operation, reducing energy consumption and operating costs.

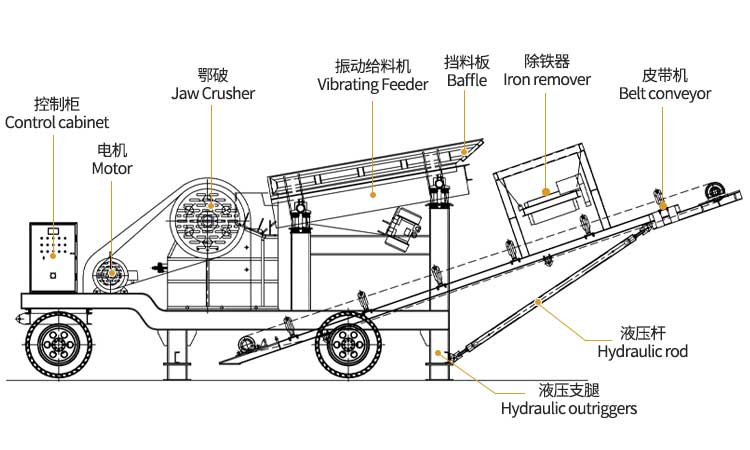

1. Feeding stage: Add the materials to be crushed into the crushing chamber of the portable jaw crusher through the feed port. The size and shape of the feed opening may be adjusted according to the materials to be processed to ensure smooth feeding. At the same time, in order to prevent large pieces of material or foreign objects from causing damage to the equipment, the feeding stage may also include screening and impurity removal steps.

2. Rough breaking stage: The materials entering the crushing cavity first pass through the rough crushing stage. The task of this stage is to convert materials from large pieces into small pieces for subsequent crushing and screening. Coarse crushing is usually accomplished through the movable jaw plate and fixed jaw plate of the jaw crusher. Driven by the motor, the movable jaw plate performs periodic swing motion along the swing track of the fixed jaw plate, exerting pressure on the material to gradually break it.

3. Conveying stage: The coarsely broken materials are transported to the designated location through conveying equipment (such as a belt conveyor). The conveying equipment can adjust the speed and direction as needed to ensure that materials can be transported continuously and stably.

|

Transport size

|

|||||

|

|

Length(mm)

|

Width(mm)

|

Height(mm)

|

Total weight(kg)

|

Main unit(kg)

|

|

|

6000

|

2350

|

3100

|

9600

|

6800

|

|

Main unit

|

|||||

|

Jaw crusher

|

Model

|

Feed opening(mm)

|

Discharging hole setting range(mm)

|

Motor Power(kw)

|

Capacity(t/h)

|

|

PE400x600

|

400x600

|

40-100

|

30kw

|

30-60t/h

|

|

|

Feeder vibrating

|

Model

|

Size of Feed Spout(mm)

|

Max Feeding size(mm)

|

Motor Power(kw)

|

Capacity (t/h)

|

|

ZSW6520

|

650x2500

|

560

|

5.5x2

|

50-90t/h

|

|

|

Belt

|

Model

|

Width(mm)

|

Length(mm)

|

Motor Power(kw)

|

|

|

B500

|

500

|

6000

|

4kw

|

||

|

Capacity(t/h)

|

30-60t/h

|

||||

Have Any Questions!

Don't Hesitate To Contact Us AnyTime.

If you need further information,please fill in your questions and comments in the form below.

Representatives from Baichy machinery will be back to you within the hour,thanking you for your support to Baichy machinery