Agitator are mainly used for mixing before flotation to ensure that the reagents and slurry are fully mixed; their main purpose is to fully mix the slurry and reagents to create conditions for mineral processing.

Agitator for Mining Industry Applications

Agitator for Mining Industry Applications

Agitator for Mining Industry Applications

Agitator for Mining Industry Applications

The mining industry has extensively benefited from our ability to refurbish and improve upon existing mixing systems. We can produce not only power savings, but also increase the operational life of existing Agitators.

The professional mixing design of the mining mixing barrel, such as the radial circulation spiral impeller, can ensure that the slurry and the reagent are fully mixed and reacted in the barrel. This efficient mixing effect helps to improve the efficiency of flotation or other mineral processing processes.

The mining mixing barrel usually adopts a compact design, which occupies a small area and is easy to arrange and install on the mine site. This compact structure also reduces the use of materials and reduces costs.

The mixing barrel is usually made of high-strength materials and has a long service life. At the same time, its internal structure and key components such as the impeller are also optimized to resist wear and corrosion in the slurry, ensuring long-term and stable operation of the equipment.

The operation of the mining mixing barrel is relatively simple and easy to master.

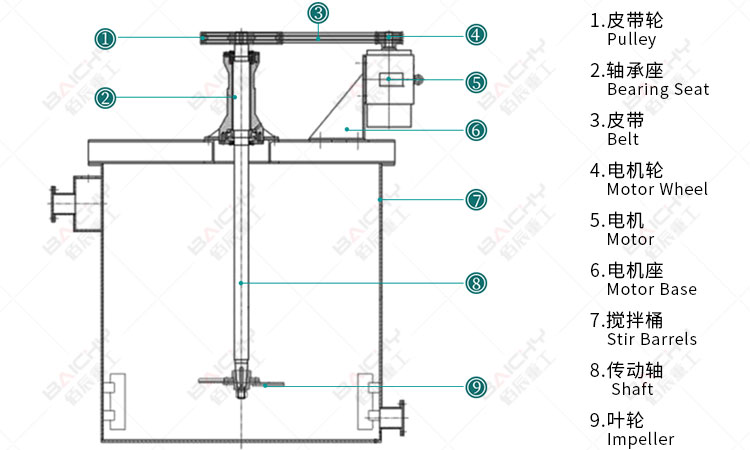

1. Power transmission: Mining mixers usually use electric motors as power sources. The power of the motor is transmitted to the core components of the mixing system through a transmission device (such as a V-belt drive).

2. Mixing action: The core component of the mixing system is a mixing cylinder or a mixing barrel, which is equipped with a mixing blade or impeller. When the motor is started, the mixing blade or impeller is driven by the transmission device to rotate at high speed in the mixing cylinder. This high-speed rotation causes the materials in the mixing cylinder (such as ore pulp, reagents, etc.) to be strongly stirred and impacted, thereby achieving uniform mixing of the materials.

3. Material mixing: Under the stirring action of the mixing blade or impeller, the materials are repeatedly turned, sheared, and mixed in the mixing cylinder. This mixing process not only ensures uniformity between the materials but also promotes the chemical reaction or physical action between the materials and the reagents.

4. Discharge and circulation: After the mixing is completed, the mixture is sent out through the discharge pipe under the mixing cylinder for subsequent process use. In some cases, in order to further improve the mixing effect, the mixer will be equipped with a circulation device to return part of the mixture to the mixing cylinder for re-mixing.

| Model | Internal diameter(mm) | Internal Height(mm) | Volume(m3) | Impeller speed(r/min) | Impeller diameter(mm) | Motor power | Dimension (LxWxH) (mm) | |

| Model | Power(KW) | |||||||

| XB-500 | 500 | 500 | 0.098 | 600 | 200 | Y90S-6 | 1.1 | 600×566×954 |

| XB-750 | 750 | 750 | 0.33 | 530 | 255 | Y90L-4 | 1.5 | 1131×880×1241 |

| XB-1000 | 1000 | 1000 | 0.58 | 350 | 240 | Y90L-4 | 1.5 | 1131×1130×1492 |

| XB-1200 | 1200 | 1200 | 1.18 | 320 | 400 | Y132S-6 | 2.2 | 1500×1480×1800 |

| XB-1500 | 1500 | 1500 | 2.2 | 320 | 400 | Y132S-6 | 3 | 1750×1640×2190 |

| XB-2000 | 2000 | 2000 | 4.4 | 240 | 550 | Y132M2-6 | 5.5 | 2380×2162×2850 |

| XB-2500 | 2500 | 2000 | 9.2 | 272 | 650 | Y160L-6 | 11 | 3036×2716×3543 |

| XB-3000 | 3000 | 3000 | 19.1 | 220 | 700 | Y225S-8 | 18.5 | 3604×3216×4250 |

| XB-3500 | 3500 | 3500 | 30 | 183 | 850 | Y225M-8 | 30 | 3940×3766×5386 |

If you need further information,please fill in your questions and comments in the form below.

Representatives from Baichy machinery will be back to you within the hour,thanking you for your support to Baichy machinery