The vibrating feeder is used for crushing over 120 kinds of rocks, such as limestone, granite, quartz, basalt, river stone, gold ore, iron ore, coal, gravel, aggregate, etc. Different final output sizes could meet your different needs.

Have low noise and can help to improve working environment.

There are many wear-resistant parts, all of which are made of high-quality steel. Even if it is used for a long time, the wear and tear of the machine are very small, so you can use it with confidence.

Our vibrating feeder can transport large volumes of material with a capacity of 30–600 t/h. And the feeding is uniform and the continuous performance is good.

Special grid design and adjustable grid gap can prevent material from clogging. In addition to this, it has a strong load-bearing structure that can withstand bulky materials.

Baichy vibrating feeder has low noise, low energy consumption, no flushing phenomenon, good comprehensive performance, and adopts a closed structure to reduce dust pollution.

The vibrating feeder is widely used to match the crushing and sieving equipment in many industries including stone crushing plants, metallurgy, coal mine, mineral dressing, building material, chemical, grinding, etc.

The vibrating feeder is used for crushing over 120 kinds of rocks, such as limestone, granite, quartz, basalt, river stone, gold ore, iron ore, coal, gravel, aggregate, etc. Different final output sizes could meet your different needs.

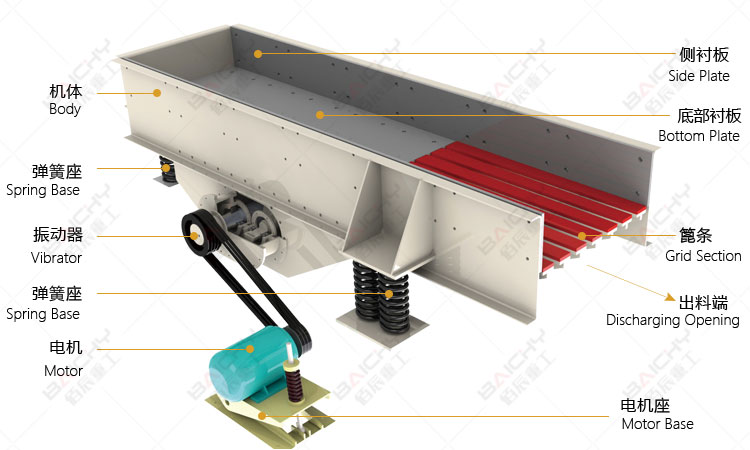

The vibrating feeder is composed of a feeding trough, a vibrator, a spring support, and a transmission device. It generates a huge linear exciting force under the drive of the motor, which makes the machine's body vibrate.

Under this vibration, the material moves forward on the trough and is transported into the crusher.

When the materials pass through the sieve bars on the tank body, the larger materials directly enter the crusher, and the smaller materials fall from the gaps in the sieve bars, which also achieves some screening effects and improves work efficiency.

| Model | Trough size(mm) |

Max feed size(mm) |

Capacity (t/h) |

Motor Power (kw) |

Overall dimension L*W*H(mm) |

| ZSW650×2500 | 650×2500 | 560 | 50-90 | 1.1×2 | 2570×890×1000 |

| ZSW850×3000 | 850×3000 | 780 | 80-120 | 7.5 | 3110×1800×1100 |

| ZSW960×3800 | 960×3800 | 820 | 120-210 | 11 | 3850×1950×1100 |

| ZSW1100×4200 | 1100×4200 | 1000 | 200-430 | 15 | 4400×2050×1200 |

| ZSW1100×4900 | 1100×4900 | 1000 | 280-500 | 18.5 | 5200×2050×1200 |

| ZSW1300×4900 | 1300×4900 | 1100 | 450-600 | 22 | 5200×2350×1400 |

| ZSW1300×6000 | 1300×6000 | 1100 | 450-680 | 22 | 6300×2300×1400 |

| ZSW1500×6000 | 1500×6000 | 1280 | 550-1200 | 30 | 6300×2550×1400 |

Have Any Questions!

Don't Hesitate To Contact Us AnyTime.

If you need further information,please fill in your questions and comments in the form below.

Representatives from Baichy machinery will be back to you within the hour,thanking you for your support to Baichy machinery