CS Symons cone crusher occupies an important position in the crushing industry with its high-efficiency crushing capacity, easy adjustment and maintenance, high reliability and durability, low operating cost, and wide adaptability.

Symons cone crusher is a high-performance cone crushing equipment designed and developed based on the principle of laminated crushing and the concept of more crushing and less grinding, based on the introduction and absorption of foreign technology, according to customer needs.

CS series standard cone crushers usually handle materials of various hardness; short-head cone crushers are suitable for medium and fine crushing operations. Its crushing chamber design makes it more efficient when handling finer materials and has better product particle size; specific models include CS110, CS160, CS220, etc.

Through the optimized design of the chamber and the combination of reasonable speed and stroke, this model can do the most work under the same moving cone diameter, thus having higher performance and production capacity.

When non-crushed objects such as iron blocks enter the machine, the iron protection device will automatically release them and then automatically reset them. It has a fixed discharge port return point and can quickly restore the original discharge port.

The combination of a high-performance crushing chamber and high crushing frequency greatly improves the processing capacity, and the crushed products are mostly cubic structures, reducing needle-like materials.

Symons cone crusher adopts the principle of laminated crushing, which significantly increases the proportion of cubes in the product, reduces needle-like stones, makes the particle size more uniform, and the cubic finished product can reach more than 75%.

Symons cone crusher is suitable for crushing various ores and rocks with medium and above hardness, especially for iron ore, gold ore, non-ferrous metal ore, granite, basalt, diabase, quartzite, etc.; it is widely used in metallurgy, building materials, road construction, chemical industry and silicate industry, as well as metal and non-metal mines, cement plants, construction, transportation, sand and gravel aggregate production and other industries.

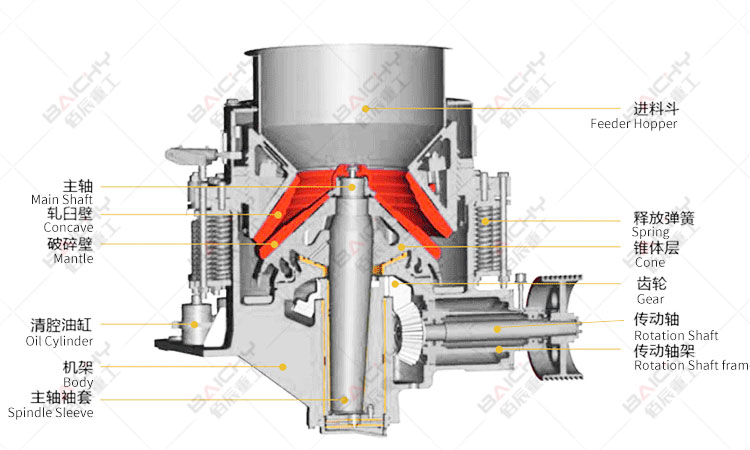

• Core components: The CS cone crusher mainly comprises frame, cone (including dynamic cone and static cone), crushing wall, transmission device, crushing chamber, adjustment device, and other parts. Among them, the cone is the core part of the crusher, which is composed of a dynamic cone and a static cone.

• Transmission mode: The motor transmits power to the cone part through a pulley or coupling, cone crusher transmission shaft and other devices. The cone part swings around a fixed point under the force of the eccentric sleeve.

• Compression and crushing: The material is compressed by the cone and the wall in the cone-crushing chamber. The eccentric shaft of the cone makes the cone rotate in the crushing chamber, thereby generating pressure and impact force. The material is compressed, bent, and sheared between the dynamic cone and the static cone, thereby achieving the crushing effect. This lamination crushing method helps to form a more uniform particle size distribution.

| Model | Cavity Type | Crushing Cone Diameter(mm) |

Adjusting Range of Discharge Opening(mm) |

Max feeding size (mm) |

Capacity (t/h) |

Motor (kw) |

Overall size (mm) |

| CS75 | Coarse | 900(3') | 25-38 | 150 | 59-163 | 75 | 2450×1820×2100 |

| CS75 | Medium | 900(3') | 13-38 | 85 | 45-91 | 75 | 2450×1820×2100 |

| CS75 | Fine | 900(3') | 6-22 | 35 | 27-90 | 75 | 2450×1820×2100 |

| CS110 | Coarse | 1200(4') | 15-50 | 180 | 110-250 | 110 | 2485×2050×2445 |

| CS110 | Medium | 1200(4') | 10-38 | 130 | 80-180 | 110 | 2485×2050×2445 |

| CS110 | Fine | 1200(4') | 10-31 | 90 | 63-140 | 110 | 2485×2050×2445 |

| CS160 | Coarse | 1295(4 1/4') | 19-50 | 205 | 172-349 | 132 | 2885×2320×2855 |

| CS160 | Medium | 1295(4 1/4') | 16-38 | 178 | 132-253 | 132 | 2885×2320×2855 |

| CS160 | Fine | 1295(4 1/4') | 13-31 | 115 | 109-181 | 132 | 2885×2320×2855 |

| CS220 | Coarse | 1400(4 1/2') | 30-60 | 235 | 210-530 | 220 | 3153×2358×2750 |

| CS220 | Medium | 1400(4 1/2') | 22-45 | 180 | 180-475 | 220 | 3153×2358×2750 |

| CS220 | Fine | 1400(4 1/2') | 19-40 | 100 | 130-260 | 220 | 3153×2358×2750 |

| CS250 | Coarse | 1650(5 1/2') | 30-60 | 228 | 299-635 | 250 | 3410×2620×3350 |

| CS250 | Medium | 1650(5 1/2') | 25-50 | 205 | 258-417 | 250 | 3410×2620×3350 |

| CS250 | Fine | 1650(5 1/2') | 20-45 | 178 | 181-327 | 250 | 3410×2620×3350 |

| CS315 | Coarse | 2135(7') | 31-64 | 314 | 1125-1814 | 400 | 4613×3302×4638 |

| CS315 | Medium | 2135(7') | 25-51 | 284 | 862-1424 | 400 | 4613×3302×4638 |

| CS315 | Fine | 2135(7') | 19-38 | 236 | 544-1034 | 400 | 4613×3302×4638 |

Have Any Questions!

Don't Hesitate To Contact Us AnyTime.

If you need further information,please fill in your questions and comments in the form below.

Representatives from Baichy machinery will be back to you within the hour,thanking you for your support to Baichy machinery