Ceramic ball mill is a grinding equipment with ceramic material as the core component, mainly used for crushing, mixing, or homogenizing materials. Its grinding tank (cylinder) and grinding media (balls) are made of high-hardness, corrosion-resistant ceramics (such as alumina, zirconium oxide, etc.). The mechanical force generated by rotation causes collision and friction between the material and the ceramic ball, thereby achieving the purpose of fine particles or uniform mixing.

Material Characteristics: Key components (tank body, grinding balls) are made of ceramic materials to ensure no metal pollution, corrosion resistance, and wear resistance.

Function: Used for crushing, mixing, grinding, and homogenizing materials, especially for high-purity or chemically sensitive materials.

Working Principle: Relying on the rotation of the tank to drive the ceramic ball to move, and grinding is achieved through impact and friction.

Application Scenarios: Ceramic industry, electronic materials, chemical industry, medicine, and other fields with high requirements for purity or corrosion resistance.

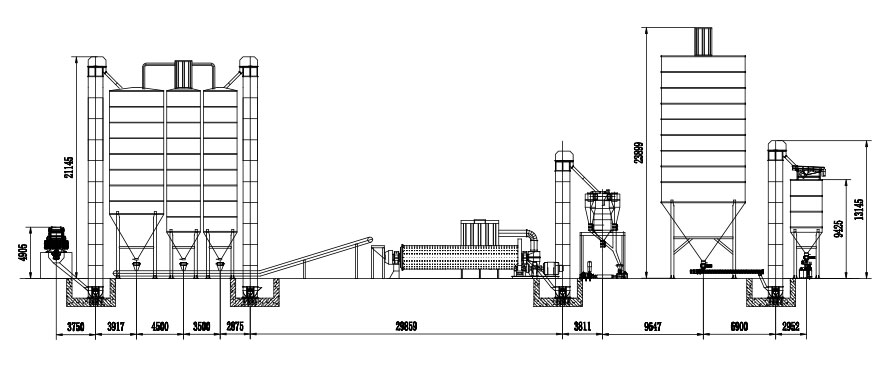

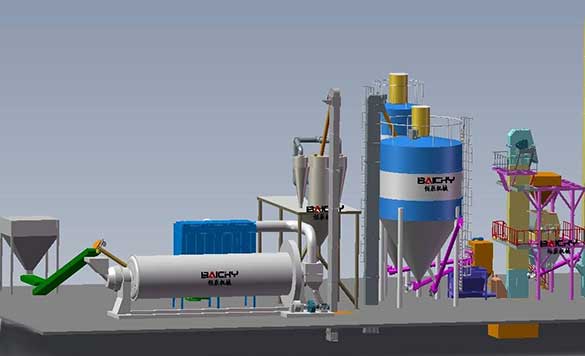

Ceramic ball mill production site

Ceramic Ball mill

Ceramic lining

Ceramic Ball

Metal ball mill: The tank is made of stainless steel or alloy, which may introduce metal impurities, and is suitable for ordinary mineral grinding.

Ceramic ball mill: Designed for high purity and pollution-free requirements, it is a key equipment for the preparation of special materials.

Grinding jar (cylinder): usually made of wear-resistant ceramics such as high-aluminum ceramics, zirconium oxide, or silicon carbide, which is corrosion-resistant and avoids metal pollution.

Grinding media (balls): ceramic balls (such as alumina, zirconium oxide, etc.), different materials and sizes can be selected according to needs.

Transmission system: The motor drives the grinding jar to rotate through gears or belts, causing the balls to collide and rub with the materials.

Support device: including bearings, brackets, etc., to ensure stable operation.

All parts that come into contact with materials (tanks, grinding balls) are made of ceramic (such as alumina, zirconium oxide) to avoid the mixing of metal ions such as iron and chromium.

Ceramics have excellent chemical stability and can withstand corrosive media such as acids, alkalis, and organic solvents. They are not easy to react to or dissolve after long-term use.

Ceramics have high hardness (such as zirconium oxide hardness ≥ 9 Mohs), are more wear-resistant than metals, extend equipment life, and reduce the frequency of medium replacement.

The ceramic surface is smooth, the material is not easy to adhere to, there is little residue, it is easy to clean, and cross-contamination between batches is avoided.

Set parameters: adjust the speed (usually 60%~75% of the critical speed) and grinding time (several hours to dozens of hours).

Start operation: The motor drives the tank to rotate, and the ceramic balls throw, hit, and rub the materials under the action of centrifugal force to achieve crushing and mixing.

Wet grinding/dry grinding selection:

• Dry grinding: Directly grind the powder, suitable for most materials.

• Wet grinding: Add water or solvent (such as ethanol) to reduce dust and increase fineness (commonly used for nano-level grinding).

Stop and stand: After grinding, stand for a while to separate the balls from the material.

Screening and collection: Separate the grinding balls from the finished powder through a sieve or filter.

Fineness detection: Use a laser particle size analyzer or sieving method to confirm whether the particles meet the requirements (adjustable parameters for secondary grinding).

| Model | Capacity(t/h) | Rotate speed(r/min) | Grinding Balls(t) | Motor Power(kw) | Gear box | |

|---|---|---|---|---|---|---|

| Model | Speed Ratio | |||||

| Ф1.2x4.5 | 1.6-5.8 | 30.3 | 5 | 55 | ZD30 | 4.5 |

| Ф1.5x5.7 | 3.5-6 | 26.34 | 11 | 130 | ZD40 | 4 |

| Ф1.83x6.4 | 6.5-15 | 23.9 | 21 | 210 | ZD60 | 4.5 |

| Ф1.83x7 | 7.5-17 | 24.5 | 23 | 245 | ZD60 | 4.5 |

| Ф2.2x6.5 | 14-20 | 21.4 | 31 | 280 | ZD70 | 5 |

| Ф2.4x7 | 17-28 | 20.4 | 39 | 380 | ZD80 | 5 |

| Ф2.4x8 | 20-35 | 20.3 | 42 | 570 | ZD80 | 5 |

| Ф2.4x12 | 35-45 | 20 | 63 | 800 | MBY710 | 6.3 |

| Ф2.4x13 | 35-38 | 19.4 | 68 | 800 | MBY710 | 6.3 |

| Ф2.6x13 | 40-55 | 19.5 | 82 | 1000 | JDX800 | 6.3 |

| Ф3x9 | 50-55 | 18.34 | 78 | 1000 | JDX800 | 6.3 |

| Ф3.2x9 | 60-70 | 17.6 | 95 | 1250 | MBY900 | 7.1 |

| Ф3.5x11 | 75-85 | 16.8 | 150 | 1250 | JDX900 | 5.84 |

| Ф3.8x12 | 85-110 | 17 | 175 | 1600 | MBY800 | 5.6 |

| Ф4.6x10+3.5 | 180-210 | 15 | 278 | 3550 | JQS3500 | 15.1 |

• High-purity materials (such as electronic ceramics, positive and negative electrode materials of lithium batteries)

• Corrosive materials (powders in acids, alkalis, and organic solvents)

• Hard and brittle materials (quartz, silicon carbide, aluminum oxide, etc.)

• Medical and food-grade powders (avoid metal contamination)

• Superhard materials (such as diamonds and tungsten carbide) that may damage the ceramic tank

• Coarse crushing that requires extremely high impact force (ceramics are brittle and easy to break)

Typical range: 0.1~100 microns (μm), depending on:

• Grinding time (the longer, the finer)

• Ball-to-material ratio (the more balls, the higher the grinding efficiency)

• Speed (needs to be optimized, too high may reduce efficiency)

Nano-level grinding: requires small-sized zirconia balls (such as 0.1mm) and planetary ball mills.

| Material | Features | Applicable scenarios |

| Destruction (Al2O₃) | Economical, wear-resistant, high hardness | Ordinary ceramic powder, glaze |

| Zirconium oxide (ZrO2) | High density, higher grinding efficiency | Nanomaterials, high-porosity materials |

| Silicon carbide (SiC) | Super hard, but high cost | Special ultra-fine grinding |

1. Avoid overloading: The total volume of material + ball should not exceed 50%~60% of the tank body.

2. Control the speed: Generally 60%~75% of the critical speed (critical speed ≈ 42.3/√tank diameter, unit: rpm).

3. Anti-impact: Do not stop or start suddenly to avoid sudden heating of ceramics.

4. Regular inspection: Observe whether the tank body has cracks before use.

| Comparison Items | Ceramic ball mill | Metal ball mill |

| Pollution risk | No metal pollution | May introduce impurities such as iron and chromium |

| Corrosion resistance | Resistant to acids, alkalis, and solvents | Easily corroded, requires stainless steel lining |

| Cost | Ceramic parts are more expensive | Low initial cost, but frequent maintenance |

| Applicable scenarios | High purity, fine grinding | General mineral, metal powder crushing |

If you need further information,please fill in your questions and comments in the form below.

Representatives from Baichy machinery will be back to you within the hour,thanking you for your support to Baichy machinery