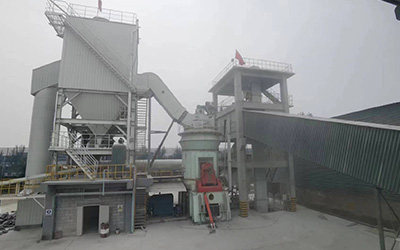

Vertical roller mill, also known as a vertical mill, is an advanced grinding equipment; it is an efficient equipment that integrates fine crushing, drying, grinding, and conveying.

Vertical roller mills are mainly used for grinding materials such as cement raw materials, cement clinker, steel slag, and coal slag.

Vertical roller mills are used to grind limestone, clay, raw materials, slag, nickel slag, manganese slag, cement, blast furnace slag, GGBS powder, fly ash coal, etc.

It can also be used to process various metal ores, such as iron ore, copper ore, etc., to provide qualified raw materials for the smelting process.

Saving 40% -50% power consumption compared to ball mill. the grinding roller grinding table does not direct contact during the grinding process, so the noise of the whole system is low.

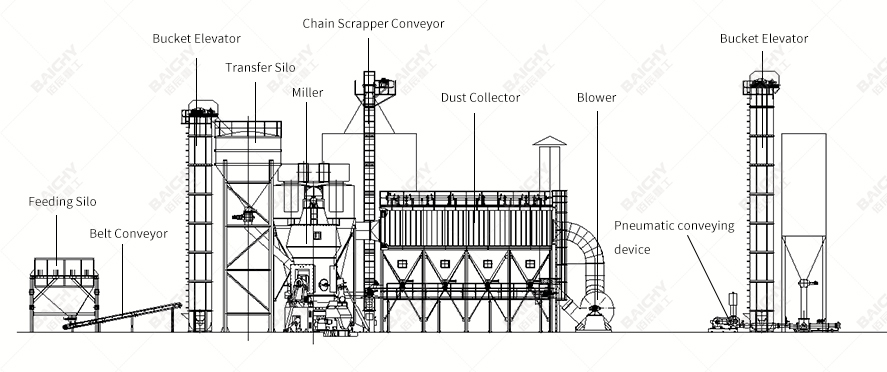

It integrates crushing, drying, grinding, powder selection, and conveying into one, with a simple process flow and compact layout; Small footprint, can be arranged in the open air, low construction cost.

The product has a narrow particle size distribution, uniform particle shape, and good fluidity. Grinding roller bearings are lubricated with forced thin oil, which longer bearing life.

Adopt a fully automatic control system, that can realize remote control, easy to operate.

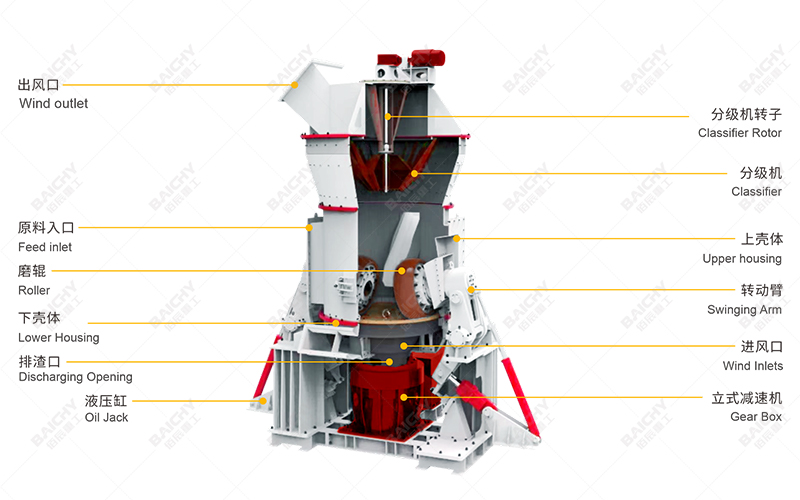

The vertical rolling mill has two pairs of grinding rollers. Each pair of the roller is composed of two narrow rollers mounted on the same axis and can rotate at different speeds. The motor driving reducer makes the grinding plate rotate. The raw material is sent to the center of the rotating grinding plate by the locking air feeding equipment. Under the action of centrifugal force, the material moves to the surrounding area of the grinding plate and enters the grinding roller slide. Under the action of roller pressure, the material is crushed by extrusion, grinding, and shearing. At the same time, the ground material is flowed by hot air upward from the wind ring. The coarse granularity will be back to the mill to regrind and suspended material will be dried. Fine powder following hot air is taken to the classifier system. Qualified powder enters the powder collector with airflow as finished products. Unqualified powder falls to be regrinded with new feeding material together. This cycle is continuous to complete the whole grinding process.

| Model | Grinding table dia.(mm) | Max feeding size(mm) | Discharge size(um) | Discharge size(mesh) | Air-in tempreture(℃) | Air-out tempreture(℃) | Input material moisture | Final moisture | Capacity(t/h) | Motor Power(kw) |

| SRM1300 | 1300 | ≤38 | 212-45 | 70-325 | ≤350 | 70-95 | 4-15% | ≤1% | 10-35 | 185-250 |

| SRM1500 | 1500 | ≤38 | 212-45 | 70-325 | ≤350 | 70-95 | 4-15% | ≤1% | 13-48 | 250-355 |

| SRM1700 | 1300 | ≤38 | 212-45 | 70-325 | ≤350 | 70-95 | 4-15% | ≤1% | 18-68 | 355-600 |

| SRM1900 | 1900 | ≤38 | 212-45 | 70-325 | ≤350 | 70-95 | 4-15% | ≤1% | 23-85 | 450-600 |

| SRM2200 | 2200 | ≤38 | 212-45 | 70-325 | ≤350 | 70-95 | 4-15% | ≤1% | 36-135 | 710-1000 |

If you need further information,please fill in your questions and comments in the form below.

Representatives from Baichy machinery will be back to you within the hour,thanking you for your support to Baichy machinery