HGM micro powder mill is a high-efficiency grinding equipment that uses high-pressure spring boosting technology. It is mainly used to process non-flammable, explosive, and brittle materials with Mohs hardness ≤ 6 and crush them into micron-level (5-45μm) fine powder. Its core principle is to achieve fineness control through high-pressure rolling and shearing between the grinding roller and the grinding ring, combined with a grading system, and finally obtain ultra-fine powder with high uniformity.

Ultra-fine processing capacity (80-2500 mesh, some models can reach 3000 mesh).

High efficiency and energy saving (motor power 37-132kW, processing capacity 0.2-20 t/h).

Dry production, no pollution, suitable for environmental protection requirements.

Applicable materials: limestone, calcite, bentonite, barite, talc, feldspar, dolomite and other 100+ minerals.

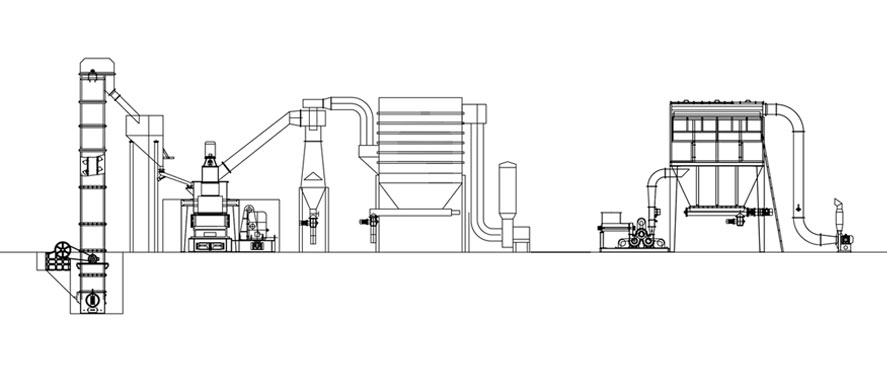

Micro powder grinding production line

HGM Micro-powder Grinding Mill

Micro powder grinding feed port

Finished product display

Core components: main machine (grinding roller, grinding ring, classifier), dust removal system, fan, feeder, pulse powder collector.

Crushing: The material enters the storage bin after being pre-crushed by the hammer crusher.

Grinding: The centrifugal force drives the grinding roller to crush the material, and the three-layer cycle is crushed to a micron level.

Classification: air flow sorting, coarse powder is returned to the mill, and fine powder is discharged through the cyclone collector.

Three-ring/four-ring grinding roller design improves grinding efficiency; variable frequency classifier, one-button adjustment of finished product fineness (quick replacement of classification wheel in 30-60 minutes).

HGM series micro powder mill mainly has the characteristics of stable operation performance, high reliability, advanced technology, long service life, and convenient maintenance.

Wide range of fineness: 80-2500 mesh, meeting the full scene requirements from building fillers to high-precision materials (such as lithium battery graphite).

Intelligent adjustment: Through the variable frequency grading wheel or quick replacement of the grading wheel,the fineness can be flexibly switched, saving the cost of multiple equipment investments.

Energy consumption is reduced by 40%: the three-ring layered rolling design, compared with the traditional ball mill, the unit power consumption is only 50-80kW·h/ton, and the annual electricity bill of 10,000-ton enterprises is over one million.

Large processing capacity: up to 20 tons/hour, supporting 24-hour continuous production, and increasing production capacity by 3 times.

Fully enclosed dry process: no wastewater, dust emission, noise ≤85dB, easily passed the environmental impact assessment.

Zero waste of raw materials: 99% finished product conversion rate, residue recycling as building materials, comprehensive utilization rate of 100%.

Hydraulic adaptive system: real-time pressure monitoring, automatic overload protection, and 70% reduction in failure rate.

Modular long-life design: The life of high-chromium alloy grinding roller/grinding ring exceeds 8,000 hours, and replacement only takes 2 hours, and the maintenance cost is halved.

Three-ring grinding system: The main motor drives the grinding disc to rotate at high speed. The material is thrown to the edge of the grinding disc under the action of centrifugal force and enters the gap between the grinding roller and the grinding ring to form three-layer crushing:

1. First layer rolling: 3-4 hydraulic grinding rollers crush the material to a millimeter level with great pressure;

2. Circular fine grinding: The crushed material falls layer by layer, and after repeated rolling in the second and third layers, the final fineness reaches 5-45 microns (80-2500 mesh);

3. Dynamic adjustment: The hydraulic system adjusts the gap between the grinding rollers in real time, adapts to materials of different hardness, and avoids overload.

The high-pressure fan sends the powder-containing airflow into the turbine classifier:

· Accurate sorting: The high-speed classifying wheel (3000-6000r/min) generates centrifugal force, the coarse particles return to the grinding area, and the fine powder rises with the airflow;

· Flexible mesh size: The speed of the classifying wheel can be adjusted by the frequency converter, or the classifying wheel can be replaced (only 30 minutes), and the finished product of 80-2500 mesh can be quickly switched.

· Efficient dust collection: 90% of the fine powder is captured by the cyclone collector, and the residual dust is discharged after pulse dust removal and purification (dust concentration more then 20mg /m³).

| Model | Average Diameter(mm) | Ringing Roller/ Roller Ring NO |

Input Size of Main Frame(mm) |

Finished Product Size | Capacity(t/h) | Motor Power(kw) | Overall Dimension L×W×H(m) |

||||||

| Ringing Roller(pcs) |

Roller Ring NO(pcs) |

Micron | Mesh | Main Grinder | Powder Separator |

Draft Fan | Feeder | Discharge Valve |

|||||

| HGM80 | 800 | 21 | 3 | ≤ 10 | 5-47 | 3250-325 | 0.5-6 | 75 | 22 | 45 | 0.06 | 1.1 | 8.6×4.1×6 |

| HGM1028 | 1000 | 27 | 3 | ≤ 15 | 1.2-10.2 | 110 | 30 | 75 | 0.15 | 2.2 | 14.5×3.6×7.5 | ||

| HGM1036 | 1000 | 36 | 4 | ≤ 20 | 1.2-11.5 | 132 | 37 | 110 | 0.15 | 3 | 14.3×4.2×7.5 | ||

| HGM1250 | 1250 | 32-44 | 4 | ≤ 20 | 2.5-20.5 | 185 | 75 | 132 | 0.15 | 3 | 19.2×4.4×8.5 | ||

• Adjust the speed of the classifier: the higher the speed, the finer the fineness.

• Control the feed amount: feed evenly to avoid overload and ensure sufficient grinding.

• Replace the screen or blades (applicable to some models).

• The airflow mill can be adjusted by the airflow pressure and the speed of the classifier wheel.

• Excessive hardness or humidity of the material results in reduced grinding efficiency (pre-treatment drying or pre-crushing is required).

• Wear of grinding roller/grinding ring: Regularly check and replace wearing parts.

• Blockage of pipes or fans: Clean up the accumulated powder and keep the airflow unobstructed.

• Classifier failure: Check whether the motor or blades are damaged.

• Check the fasteners: whether the bolts, grinding roller brackets, etc., are loose.

• Balance calibration: The dynamic balance of the spindle or rotor needs to be adjusted.

• Bearing damage: Bearings need to be replaced if lubrication is insufficient or worn.

• Foreign matter enters: Stop the machine to clean hard objects in the grinding chamber.

• Regular lubrication: Oil the key parts such as bearings and gears according to the instructions.

• Replace wearing parts in time: Wear of grinding rollers, grinding rings, scrapers, etc., affects efficiency.

• Control material properties: Avoid metal impurities or high-humidity materials from entering.

• Idle before shutdown: Drain residual materials to prevent agglomeration.

• Daily: Check lubrication, fasteners, and clean dust.

• Monthly: Check the degree of wear of wearing parts.

• Every six months: Comprehensively overhaul the motor and transmission system and replace the lubricating oil.

If you need further information,please fill in your questions and comments in the form below.

Representatives from Baichy machinery will be back to you within the hour,thanking you for your support to Baichy machinery