Modular crushing plants have become an important trend in the development of the aggregate crushing industry due to their advantages of integration, modular design, easy installation and maintenance, high flexibility, strong applicability, technological innovation, and intelligence.

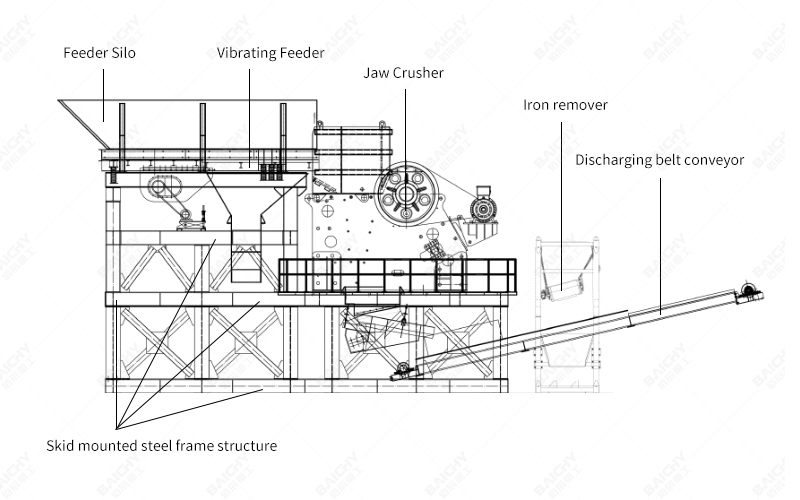

Modular crushing equipment integrates multiple functional modules such as crushing and screening through standardized design, pre-assembly, and rapid on-site assembly of unit modules such as crushing and screening to form a complete crushing and screening system.

Modular crushing equipment has been widely used in many industries due to its high flexibility, rapid installation and deployment, reduced operating costs, improved production efficiency, easy relocation and recombination, optimized space utilization, and enhanced scalability.

The design of modular crushing equipment makes it easy to dismantle and reinstall. When users need to relocate equipment or recombine equipment according to new project requirements, they can easily disassemble and transport the modules and quickly assemble them at the new site. This feature enables the equipment to flexibly adapt to different construction environments and project requirements.

Modular crushing equipment is usually equipped with comprehensive safety protection measures. For example, modular jaw crushers may have designs such as flywheels and V-belt safety shields. The equipment may also be equipped with optional accessories such as conveyor belt protection devices and guide trough safety protection windows, which further improve the safety performance of the equipment.

The application scenarios of modular crushing stations are very wide, including natural stone crushing, construction waste treatment, coal and metal mine crushing, open-pit mine crushing, and infrastructure construction. Its high efficiency, flexibility, and adaptability enable it to meet the crushing needs of different industries and different working environments.

In a modular crushing plant, each module assumes a specific function and is connected in an integrated manner. For example, the feeder module is responsible for the supply of materials, the crusher module is responsible for crushing materials, and the screening module is responsible for screening materials. The coordination between these modules ensures the efficient and stable operation of the entire crushing station.

In addition, the modular crushing plant is equipped with an advanced control system. Through PLC integrated control, the operator can know the working voltage, current, and other parameters of each driving device, thereby achieving precise control of each module of the crushing station. At the same time, through observation equipment such as windows, the operator can also directly observe the actual status of the crushed materials in the hopper and upper chute of the crusher, so that the feeding level can be adjusted in time to prevent excessive material or blockage.

| Model |

Feeder Opening Size(mm) |

Max. Feeding Size (mm) |

Outlet adjusting Size(mm) |

Capacity (t/h) |

Motor Power (kw) |

Overall Dimension (mm) |

| PE400x600 | 400x600 | 350 | 40-90 | 15-60 | 30 | 1700x1750x1680 |

| PE500x750 | 500x750 | 425 | 50-100 | 40-130 | 45 | 2150x1900x1950 |

| PE600x900 | 600x900 | 500 | 60-125 | 90-180 | 55 | 2500x2010x2350 |

| PE750x1060 | 750x1060 | 630 | 60-150 | 110-380 | 110 | 2630x2310x3110 |

| PE900x1200 | 900x1200 | 750 | 95-165 | 220-450 | 132 | 3720x2850x3250 |

| PE1000x1200 | 1000x1200 | 850 | 200-300 | 280-560 | 160 | 3820x2850x3250 |

| PE1200x1500 | 1200x1500 | 1020 | 150-300 | 400-800 | 220 | 4590×3342×3553 |

| PE1500x1800 | 1500x1800 | 1200 | 210-360 | 520-1100 | 280 | 5100x4700x4300 |

Have Any Questions!

Don't Hesitate To Contact Us AnyTime.

If you need further information,please fill in your questions and comments in the form below.

Representatives from Baichy machinery will be back to you within the hour,thanking you for your support to Baichy machinery