DG single-cylinder cone crusher occupies an important position in the field of ore crushing with its advantages of efficient crushing capacity, stability and reliability, intelligent control, energy saving and environmental protection, easy maintenance, and wide application.

DG200 and DG300 single-cylinder cone crushers have the characteristics of high crushing efficiency, moderate processing capacity, and wide application range.

DG500 single-cylinder cone crusher has a larger production capacity (200-650t/h), higher crushing efficiency, and a wider range of applications.

The single-cylinder hydraulic cone crusher adopts advanced design concepts, making it compact in structure, small in space, and easy to install and layout.

The single-cylinder hydraulic cone crusher adopts a steep slope cone design with a large swing frequency and large inclination, making its processing capacity about 40% greater than that of ordinary cone crushers.

The laminated crushing principle is adopted, and the products after crushing are mostly cubic structures, which reduces the needle-like materials and makes the particle size more uniform.

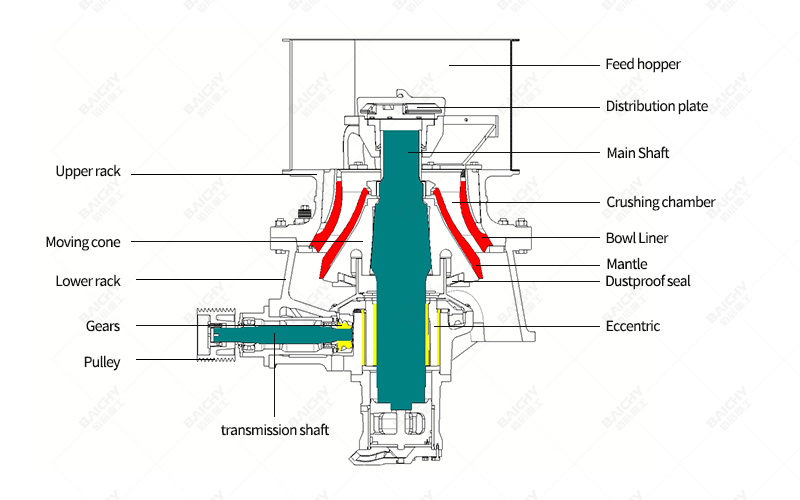

DG single-cylinder cone crusher, that is, DG series single-cylinder hydraulic cone crusher, its working principle is mainly based on the relative motion between the movable cone and the fixed cone to crush materials.

• Eccentric sleeve and main shaft: The main shaft installed in the eccentric sleeve will make periodic movements as the eccentric sleeve rotates. This movement causes the cone (moving cone) installed on the main shaft to also perform similar movements.

• Crushing wall and rolling mortar wall: The movement of the movable cone makes the crushing wall on it sometimes approach and sometimes move away from the rolling mortar wall on the fixed cone. When the crushing wall is close to the rolling mortar wall, the material between the two is squeezed and sheared, thereby achieving crushing.

| Model | Cavity Type (super coarse type) |

Feed Opening Size (mm) |

Min.Discharge Part (mm) |

Capacity (t/h) |

Power (kw) |

| Standard cavity type | |||||

|

CH420 (DG100) |

Coarse | 150 | 16 | 60-125 | 75 |

| Medium | 100 | 14 | 50-100 | ||

| Fine | 60 | 10 | 40-90 | ||

|

CH430 (DG200) |

Coarse | 185 | 16 | 70-200 | 160 |

| Medium | 150 | 14 | 60-170 | ||

| Fine | 80 | 10 | 45-110 | ||

|

CH440 (DG300) |

Coarse | 220 | 20 | 200-400 | 220 |

| Medium | 175 | 16 | 110-330 | ||

| Fine | 120 | 12 | 80-280 | ||

|

CH660 (DG500) |

Coarse | 275 | 20 | 170-670 | 315 |

| Medium | 135 | 16 | 190-510 | ||

| Fine | 85 | 12 | 200-320 | ||

| Extra Coarse Cavity Type | |||||

|

CHS430 (DG200S) |

Extra Coarse | 300 | 25 | 230-350 | 160 |

| Medium Coarse | 240 | 22 | 170-280 | ||

|

CHS440 (DG300S) |

Extra Coarse | 400 | 41 | 450-530 | 250 |

| Medium Coarse | 350 | 29 | 360-420 | ||

|

CHS660 (DG500S) |

Extra Coarse | 480 | 50 | 650-1000 | 315 |

| Medium Coarse | 380 | 45 | 500-800 | ||

Have Any Questions!

Don't Hesitate To Contact Us AnyTime.

If you need further information,please fill in your questions and comments in the form below.

Representatives from Baichy machinery will be back to you within the hour,thanking you for your support to Baichy machinery