Coal gangue and cinder: These materials are commonly used as additives in brick and tile manufacturing, and a two-stage crusher can efficiently break them to the required particle size.

The two-stage crusher has become an indispensable and important equipment in the industrial field due to its efficient, uniform, and reliable crushing performance and wide range of applications.

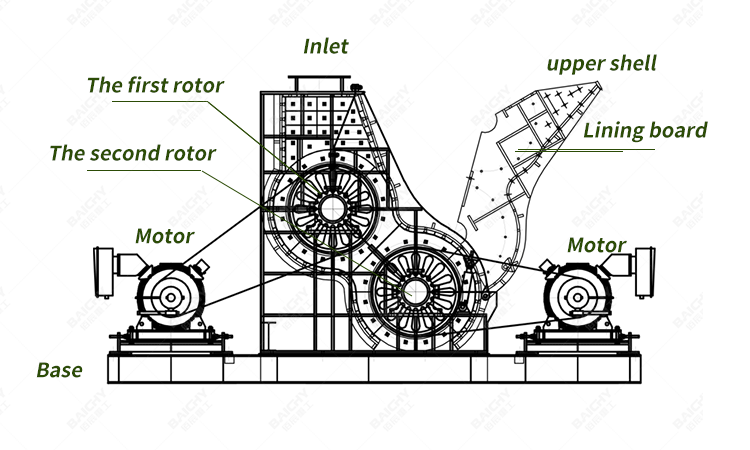

The double-stage crusher is designed with double rotors and double material chambers, which can achieve double crushing of materials, greatly improving the crushing efficiency. This design can not only handle a large amount of materials, but also the crushing effect is more uniform, which helps to improve the processing efficiency of subsequent processes.

The two-stage crusher has low requirements for material humidity and can handle materials of various humidity, such as coal gangue, shale, cinder, etc., solving the problem of wet material crushing. The crushing particle size can also be adjusted as needed to meet the needs of different users and production processes. This flexibility allows the two-stage crusher to adapt to more production scenarios.

The double-stage crusher has a reasonable structural design and is easy to maintain and repair. The operation of the equipment is stable, the failure rate is low, and it can work continuously for a long time, reducing downtime for maintenance and improving production efficiency.

During the crushing process, the double-stage crusher can reduce energy consumption and emissions through optimized design and control, achieving the effect of energy saving and environmental protection. This is an important advantage for the current industrial environment that advocates green production.

About a double-stage crusher: The mining industry: is used to crush various ores, such as calcite, limestone, etc. Construction industry: often used to process construction waste, construction waste, and other materials.Road and railway construction: In the construction of these infrastructures, double-stage crushers are used to crush various stones and provide suitable aggregates for construction.

Coal gangue and cinder: These materials are commonly used as additives in brick and tile manufacturing, and a two-stage crusher can efficiently break them to the required particle size.

During the operation of the two-stage crusher, it is driven by dual motors, so that the upper and lower sets of rotors can rotate at high speed at the same time. When the material enters the crushing chamber, it will first encounter the crushing effect of the upper rotor. The upper rotor rotates at high speed to initially crush the materials. Subsequently, the initially crushed materials will quickly enter the working area of the lower rotor.

| Model | Feeding Size(mm) | Discharge Size | Production Capacity(t/h) | Allow Material Moisture Content | power(kw) | Size(mm) |

|---|---|---|---|---|---|---|

| 2PC2000×1600 | ≤200 |

All size below 3mm: in general about 50% is 0.5~0.075mm , 35% is 0.6~2mm and the rest is 2~3mm. The discharge particle size can be adjusted as needed |

250-300 | <20% | 355+355 | 6410×3413×4260 |

| 2PC1600×1400 | ≤180 | 120-180 | 220+220 | 6000×3100×3900 | ||

| 2PC1400×1200 | ≤150 | 100-120 | 132+160 | 5800×2658×3210 | ||

| 2PC1200×1000 | ≤130 | 80-100 | 110+132 | 4086×2230×2550 | ||

| 2PC1100×1000 | ≤130 | 60-90 | 90+110 | 4086×2030×2337 | ||

| 2PC900×800 | ≤100 | 50-70 | 55+75 | 3950×1750×2280 | ||

| 2PC800×700 | ≤100 | 45-60 | 55+55 | 3485×1400×2254 | ||

| 2PC600×600 | ≤100 | 20-30 | 22+22 | 2875×1300×1650 | ||

| 2PC600×400 | ≤100 | 15-25 | 18.5+22 | 2350×926×1630 |

Have Any Questions!

Don't Hesitate To Contact Us AnyTime.

If you need further information,please fill in your questions and comments in the form below.

Representatives from Baichy machinery will be back to you within the hour,thanking you for your support to Baichy machinery