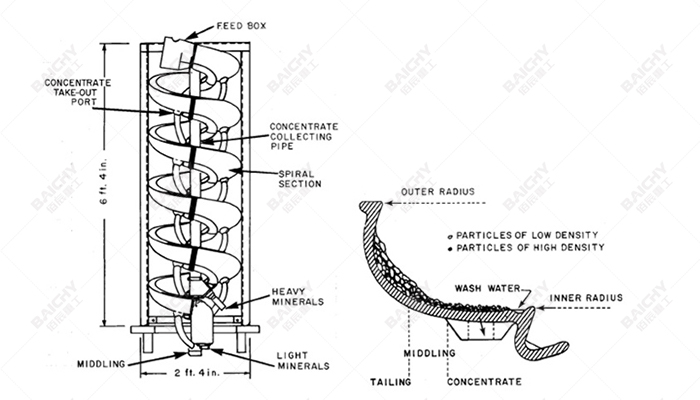

A spiral sluice is a device that uses the density differences of mineral particles in a flow of water on an inclined plane for separation. It mainly consists of a vertically arranged spiral trough. When the slurry (a mixture of mineral particles and water) is fed in from the top, it flows downwards along the spiral channel under gravity. During this process, mineral particles of different densities and sizes are subjected to the combined effects of gravity, centrifugal force, hydrodynamic force, and friction, thus stratifying and separating at different radial positions, ultimately achieving separation.

Spiral sluices are particularly suitable for separating minerals with relatively coarse particle sizes (typically 0.03-1mm) and significant density differences.

• Iron ore: separating weakly magnetic iron ore.

• Coastal placer deposits: recovering ilmenite, zircon, rutile, monazite, etc.

• Tungsten-tin ore: as a roughing or scavenging device.

• Others: also used in coal preparation, particulate matter recovery from mineral processing wastewater, etc.

Iron Ore Separation

Tungsten-Tin Ore Gravity Separation

Tailings recovery equipment

gravity separation applications

This is the most classic and widespread application of spiral sluices in China. For weakly magnetic ore such as hematite, limonite, and siderite, magnetic separation is ineffective, making gravity separation the preferred method.

How it works: After crushing and grinding, the raw ore forms a slurry. Spiral sluices effectively separate denser iron mineral particles (concentrate) from less dense gangue particles such as quartz (tailings).

Application Status: In large iron ore beneficiation plants, spiral sluices are often used as roughing or scavenging equipment to pre-enrich the ore and remove large amounts of tailings, thereby reducing the load on subsequent cleaning operations (such as flotation and high-gradient magnetic separation) and significantly lowering production costs.

Tungsten and tin minerals (such as wolframite, scheelite, and cassiterite) have very high densities, significantly different from the gangue density, making them very suitable for recovery by gravity separation. Spiral sluices have a long history in this field.

How it works: In the beneficiation process of tungsten-tin ore, spiral sluices are commonly used to process ore sand after roughing by jigs, or to directly process slurries of suitable particle size for further recovery of fine-grained tungsten-tin minerals.

Application status: It is an important part of the gravity separation process for tungsten-tin ore, especially in the processing of fine mud, and is often used in conjunction with shaking tables.

1111111

The spiral chute does not require an external power source during operation. It relies on the gravity of the material itself and the centrifugal force generated by rotation for sorting.

The spiral chute can effectively classify and separate materials according to their physical properties such as specific gravity, particle size, and shape.

The spiral chute has good adaptability to changes in parameters such as feed volume and feed concentration.

Compared with other ore dressing equipment, the spiral chute occupies a smaller area, but the productivity per unit area is very high.

1. Spiral Tank: Typically the main body, made of fiberglass or other wear-resistant materials, in a 3-5 spiral shape.

2. Feeder: Located at the top, ensuring a uniform and stable feed of slurry into the tank.

3. Cutter: Installed on the outer bottom of the tank, used to collect the separated concentrate, middlings, and tailings separately.

4. Tank Frame: Used to support and fix the entire spiral trough.

The separation process is a "symphony" of gravity, centrifugal force, water flow shear force, and friction. Dense, valuable mineral particles (such as iron ore, cassiterite, tungsten ore, etc.) settle quickly and concentrate at the inner edge of the spiral trough; while less dense gangue particles are pushed towards the outer edge by the water flow. The catcher at the bottom precisely directs the concentrate, middlings, and tailings into different collection tanks.

| Model | 5LL-1500 | 5LL-1200 | 5LL-900 | 5LL-600 | 5LL-400 |

|---|---|---|---|---|---|

| Outer Dia(mm) | 1500 | 1200 | 900 | 600 | 400 |

| Spiral Distance(mm) | 540/720 | 900/720/540 | 675/540/405 | 450/360/270 | 240/180 |

| Spiral Distance Ratio | 0.75/0.6/0.45 | 0.75/0.6/0.45 | 0.75/0.6/0.45 | 0.75/0.6/0.45 | 0.6/0.45 |

| Gradient(°) | 9 | 9 | 9 | 9 | 9 |

| Number Of Threads | 4-2 | 4-2 | 4-2 | 3 | 2 |

| Feeding Size(mm) | 0.3-0.02 | 0.3-0.03 | 0.3-0.03 | 0.2-0.02 | 0.2-0.02 |

| Feeding Density(%) | 25-55 | 25-55 | 25-55 | 25-55 | 25-55 |

| Capacity(t/h) | 8-16 | 4-6 | 2-3 | 0.8-1.2 | 0.15-0.2 |

| Overall Dimension(mm) | 1560x1560x5230 | 13601360x5230 | 10601060x4000 | 700x700x2600 | 460x460x1500 |

If you need further information,please fill in your questions and comments in the form below.

Representatives from Baichy machinery will be back to you within the hour,thanking you for your support to Baichy machinery