Three-drum dryer is a device that shortens the overall dimensions of a single-drum dryer and improves drying efficiency by replacing the single-drum body of a single-drum dryer with three stacked drums.

The three-drum dryer uses advanced heat recovery technology and efficient heat conduction and hot air circulation design, which can effectively recover and utilize heat energy, reduce energy consumption, and improve drying efficiency.

Three-cylinder drying - Rotary Dryer, Drying machine manufacturer

Three-cylinder drying - Rotary Dryer, Drying machine manufacturer

Three-cylinder drying - Rotary Dryer, Drying machine manufacturer

Three-cylinder drying - Rotary Dryer, Drying machine manufacturer

The three-drum dryer adopts advanced drying technology, which can greatly improve drying efficiency and reduce energy consumption. Compared with traditional drying equipment, its energy-saving effect can reach more than 30%.

The three-drum dryer is suitable for drying various materials, such as slag, clay, coal, iron powder, etc. At the same time, it can also be adjusted and optimized according to the characteristics and drying requirements of the materials to meet the needs of different industries.

The three-drum dryer adopts an advanced control system, which can realize automatic operation.

The waste gas generated by the three-drum dryer during the drying process can be discharged after treatment, which meets the national environmental protection requirements.

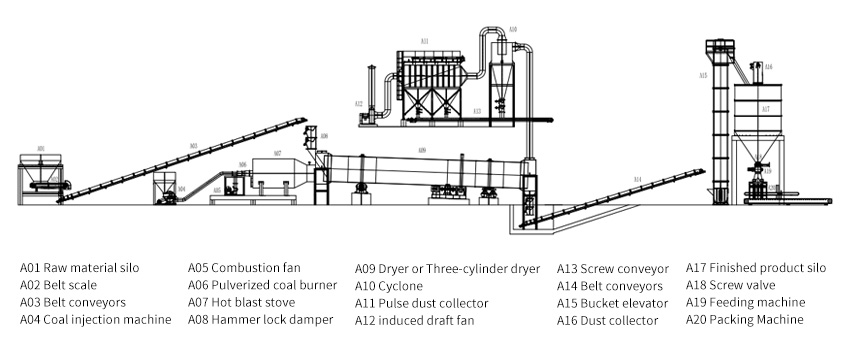

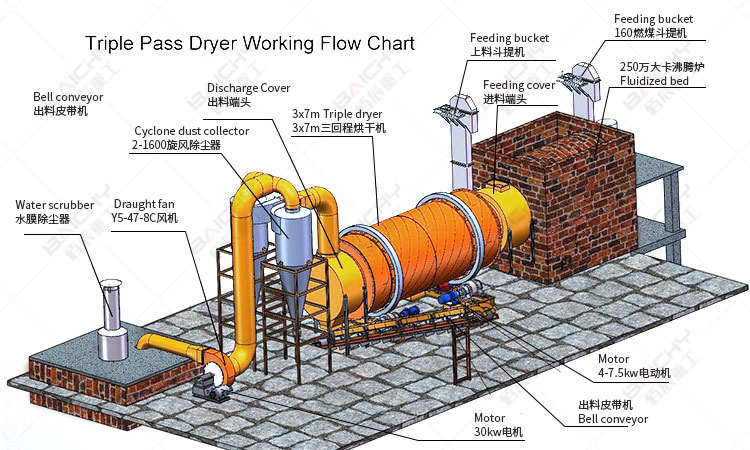

1. Material entry:The wet material is first fed into the innermost cylinder (first cylinder) of the three-cylinder dryer, where it comes into contact with the hot air at high temperature and begins preliminary drying.

2. Heat exchange process:In the first cylinder, the material undergoes preliminary heat exchange with the hot air, and most of the moisture in the material is evaporated.

Subsequently, the material enters the second cylinder (second cylinder), where it comes into contact with the hot air at a slightly lower temperature, continues the drying process, and removes the remaining moisture.

Finally, the material enters the outermost cylinder (third cylinder) and undergoes the final heat exchange with the hot air at a lower temperature but with a faster flow rate, ensuring that the material reaches the required degree of dryness.

3. Hot air circulation:During the entire drying process, the hot air is circulated through a specific system. The hot air is first heated by a burner or heater, and then enters the three-cylinder dryer for heat exchange with the material.

After the hot air exchanges heat with the material in the cylinder, it becomes hot and humid exhaust gas, which is then discharged from the dryer and processed through a dust removal and recovery system for reuse.

4. Material discharge:After drying layer by layer in the three cylinders, the material finally reaches the required degree of dryness and is discharged from the outlet of the dryer.

| Model | Diameter of outer cylinder(m) | Length of outer cylinder (m) | Drum volume(m³) | Rotation speed(r/min) | Max. air flow temperature(℃) | Production capacity(t/h) | Power(kw) |

| Ф2.0*4m | 2 | 4 | 12.56 | 4-10 | 700-750 | 8-15 | 5.5x2 |

| Ф2.2*5m | 2.2 | 5 | 18.99 | 4-10 | 700-750 | 12-20 | 5.5x2 |

| Ф2.5*6m | 2.5 | 6 | 29.43 | 4-10 | 700-750 | 18-28 | 7.5x2 |

| Ф2.8*6m | 2.8 | 6 | 36.92 | 4-10 | 700-750 | 25-35 | 11x2 |

| Ф3.0*6m | 3 | 6 | 42.39 | 4-10 | 700-750 | 30-40 | 7.5x4 |

| Ф3.0*7m | 3 | 7 | 49.45 | 4-10 | 700-750 | 30-45 | 7.5x4 |

| Ф3.2*7m | 3.2 | 7 | 56.27 | 4-10 | 700-750 | 35-55 | 11x4 |

| Ф3.6*8m | 3.6 | 8 | 81.39 | 4-10 | 700-750 | 55-75 | 18.5x4 |

| Ф4.0*10m | 4 | 10 | 125.60 | 4-10 | 700-750 | 70-100 | 22x4 |

If you need further information,please fill in your questions and comments in the form below.

Representatives from Baichy machinery will be back to you within the hour,thanking you for your support to Baichy machinery