The CI series large-mouth impact crusher adopts advanced crushing technology and design, which can achieve efficient crushing operations and improve production efficiency; the large crushing chamber has a spacious crushing chamber, which can accommodate larger feed particle sizes and reduce material pretreatment costs.

The CI series large-mouth impact crusher is crushing equipment with a large crushing chamber, efficient crushing capacity, refined design, wear resistance, durability, flexible adjustment, and easy maintenance. It is suitable for crushing materials of various hardness, including but not limited to limestone, granite, iron ore, coal gangue, construction waste, etc. Its efficient crushing capacity and wide range of applications make the CI series large-mouth impact crusher one of the important pieces of equipment in the crushing industry.

CI series large-mouth impact crusher is popular in the market for its high efficiency, energy saving, and durability. It is suitable for medium and fine crushing and can handle materials of various hardness, such as limestone, granite, etc. Its popular models are CI5X131, CI5X1415, CI5X1520, CI1316, etc. In addition to the above specific models, the CI series may also include other models such as CI1110, CI1213, etc. These models may occupy a place in the market due to their unique technical characteristics and applicable scenarios.

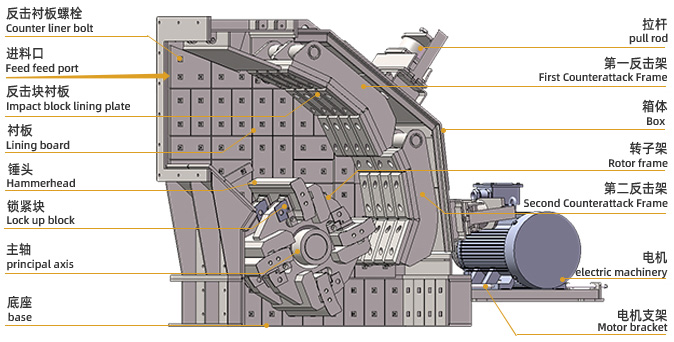

The CI Series Large Mouth Impact Crusher has a spacious crushing chamber that can accommodate larger feed particle sizes, reduce material pretreatment costs, and improve crushing efficiency; through the optimized rotor, hammerhead, and liner design, efficient crushing operations are achieved while maintaining low energy consumption; according to the crushing needs of different materials, the rotor and crushing chamber are finely designed to meet the processing requirements of coarse, medium and fine materials of different specifications; it is made of high-quality materials, such as high-quality forged alloy steel, and a large number of new high-wear-resistant materials are used to make the equipment more wear-resistant and durable, extending its service life.

The discharge particle size range of CI Series Large Mouth Impact Crusher is roughly between 5-40mm, but this range is not absolutely fixed, and the actual discharge particle size can be adjusted according to user needs; materials of different hardness and properties will produce different crushing effects during the crushing process, thereby affecting the discharge particle size; the size of the feed particle size will directly affect the crushing effect and discharge particle size of the crusher. Larger feed particle sizes may require greater crushing force and longer crushing time, resulting in relatively larger discharge particle sizes.

The CI series large-mouth impact crusher is suitable for crushing materials of various hardness, including but not limited to limestone, coal gangue, granite, iron ore, feldspar, calcite, talc, construction waste, etc. Its wide applicability makes it widely used in industrial sectors such as metallurgy, mining, cement, and chemical industries, as well as in highways, water conservancy projects, and construction projects.

The crushing principle of the CI series large-mouth impact crusher is mainly to use impact energy to crush materials. Under the joint action of a high-speed rotating rotor and fixed impact plate, the material is subjected to strong impact and extrusion, thereby achieving crushing. In addition, the multiple collisions and frictions of the material in the crushing chamber also further promote the crushing effect.

• Efficient crushing: Through the optimized design of the rotor and crushing chamber structure, efficient crushing operation is achieved.

• Large crushing ratio: It can handle large-size and high-hardness materials and achieve a higher crushing ratio.

• Wear-resistant and durable: The key components such as the plate hammer and impact plate are made of high-quality materials to increase the service life of the equipment.

• Flexible adjustment: Equipped with auxiliary equipment such as a hydraulic adjustment device, it is convenient to adjust the discharge port's size and the discharge material's particle size.

| Model | Max. Feeding Size (mm) | Motor Power (kw) | Capacity (t/h) | Overall Size |

| For Secondary Or Tertiary Crushing Stage | ||||

| CI1110 | 500 | 160 | 110-260 | 2826×2087×2285 |

| CI1213 | 550 | 200 | 145-350 | 2903×2530×2411 |

| CI1316 | 600 | 250 | 200-450 | 3320×2770×2535 |

| CI1521 | 400 | 2×(200-250) | 335-760 | 3450×3620×2770 |

| For Primary Crushing Stage | ||||

| CI1313 | 600 | 200 | 100-480 | 2972×2560×2937 |

| CI1415 | 600 | 250 | 120-600 | 2985×2790×3068 |

| CI1620 | 800 | 2×(200-250) | 220-900 | 4261×3480×3780 |

| CI2023 | 800 | 2×500 | 400-2000 | 5151×4424×4712 |

Have Any Questions!

Don't Hesitate To Contact Us AnyTime.

If you need further information,please fill in your questions and comments in the form below.

Representatives from Baichy machinery will be back to you within the hour,thanking you for your support to Baichy machinery