The crusher is specially used for fine crushing of coal to produce ≤10mm or ≤3mm finished products. It has outstanding advantages for dealing with damp and easy plugging materials.

Reversible hammer crusher is a kind of efficient, energy-saving, and adaptable crushing equipment, widely used in various industrial sectors and construction fields; it has a high crushing ratio, high efficiency, long life hammerhead, easy maintenance, excellent product shape, wide range of With its adaptability and other characteristics, it is one of the main equipment for fine crushing of materials in industrial sectors such as metallurgy, building materials, chemicals, and hydropower.

The reversible hammer crusher allows large feed particle sizes, the average particle size of the crushed products is generally below 15mm, and the crushing ratio is greater than 50, which can reduce the number of crushing stages and simplify the process. The toothed impact lining is quite suitable for hard rock crushing and is efficient and energy-saving. The power consumption per unit product is generally about 1kW·h/t. It is an energy-saving equipment in the crushing machinery.

Due to the use of a screenless grate device, the reversible hammer crusher has enhanced adaptability to material moisture, so the material discharge is smooth, the crushing efficiency is high, and the crushing fineness adjustment range is wide. The hammerhead adopts a high-strength combined hammerhead, with reinforcing ribs at the connection, and the width of the striking end is widened, which changes the phenomenon of the hammerhead falling off in traditional models and extends the life of the equipment.

The product is cubic, and the particle size of the discharged material is adjustable, which simplifies the crushing process. It is an ideal processing equipment for aggregates used in highway pavement and hydropower construction.

The crushing plate of the crusher is easy to open and maintain. It adopts a hydraulic system. Only the hammer head needs to be replaced, and the hammer handle does not need to be replaced, which greatly saves maintenance costs.

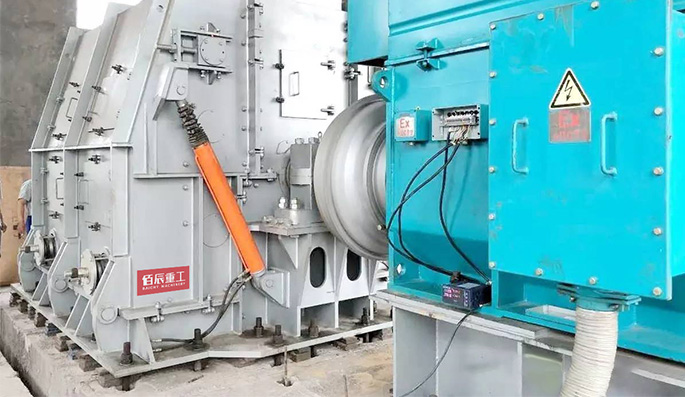

Reversible hammer crusher features large impact force and high efficiency of crushing, it is widely used in power, metallurgy, construction material, the chemical industry, etc. for fine crushing of coal and rock with hardness less than 150MPa.

The crusher is specially used for fine crushing of coal to produce ≤10mm or ≤3mm finished products. It has outstanding advantages for dealing with damp and easy plugging materials.

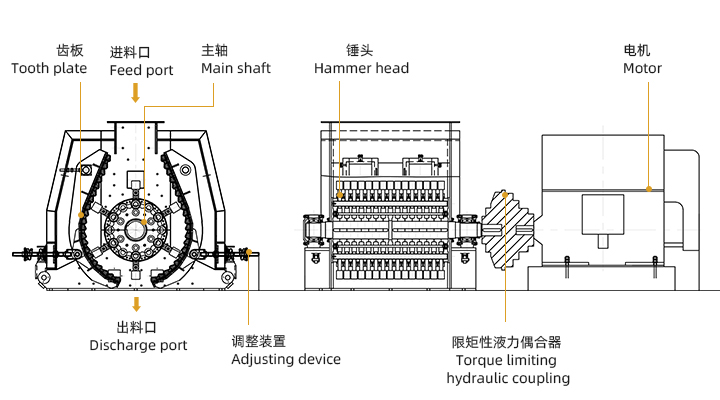

Reversible hammer crusher is a new type of crushing equipment, general configuration by crusher main engine, motor, torque limiting hydraulic coupling, liquid opening device. The spindle and hammer handle are forged with 42CrMo alloy steel. The hammer head and village plate are cast with high wear-resisting alloy. Because it is different from the design concept of ordinary crusher, the structure of the large rotor, short pin shaft, reversible rotary combination hammer, has the advantages of large impact, easy operation and maintenance, low operation cost. PCK series reversible hammer crusher, used for crushing brittle materials with medium hardness of ore compressive strength not more than 150Mpa (1500 kg/square cm), such as coal, limestone, gypsum, soft refractory materials, etc.

| Model | Rotor Size(mm) | Feed Size(mm) | Finished Size(mm) | Production Capacity(t/h) | Power(kw) |

| PCK0808 | φ800×800 | ≤60 | ≤15mm | 25-40 | 90 |

| PCK1010 | φ1000×1000 | ≤80 | 35-70 | 110 | |

| PCK1012 | φ1000×1250 | ≤80 | 70-90 | 132 | |

| PCK1212 | φ1250×1250 | ≤100 | 90-120 | 220 | |

| PCK1214 | φ1250×1400 | ≤100 | 120-150 | 250 | |

| PCK1416 | φ1400×1600 | ≤120 | 160-250 | 355 | |

| PCK1418 | φ1400×1800 | ≤120 | 250-300 | 400 | |

| PCK1618 | φ1600×1800 | ≤140 | 280-350 | 560 |

Have Any Questions!

Don't Hesitate To Contact Us AnyTime.

If you need further information,please fill in your questions and comments in the form below.

Representatives from Baichy machinery will be back to you within the hour,thanking you for your support to Baichy machinery