Track-mounted Mobile Impact Crusher, also known as Crawler Impact Crusher for short, is a kind of crushing machine, which is classified as mining machinery. It uses the principle of impact crushing to crush materials and is an important equipment in the crushing production line.

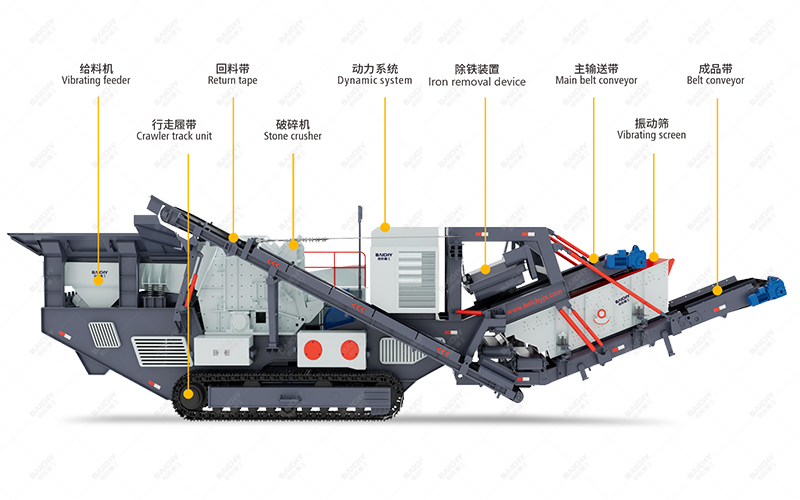

The crawler impact crusher is a high-performance crushing equipment. It combines the advantages of the impact crusher and the crawler mobile device to form a crushing production line that can operate independently and move flexibly.

The crawler impact crusher is mainly suitable for crushing materials of medium hardness, such as limestone, river pebbles, dolomite, granite, basalt, etc., and is used for crushing and screening various ores and rocks.

The crawler mobile device allows the crushing station to be easily moved to different work locations without complicated installation and disassembly processes. It has the advantages of strong mobility, high crushing efficiency, high degree of automation, energy saving and environmental protection, and convenient maintenance.

When selecting, users need to make comprehensive considerations based on their production needs, material characteristics, and working environment. At the same time, different configuration forms can be selected according to actual needs, such as adding iron removers, air separation devices, etc., to improve the comprehensive performance of the equipment.

Track-mounted Mobile Impact Crusher are widely used for coarse crushing of hard materials in the mining field of mines, coal mines, and cement industries. They can also be used for recycling garbage, earthwork, urban infrastructure, roads or construction sites, etc. They can also be used for stripping and crushing of road reconstruction and crushing of asphalt concrete before recycling.

The raw materials are sent to the silo by equipment such as forklifts and excavators, and the materials in the silo enter the screening feeder. Among them, the part of the raw materials that meet the particle size requirements leaks out from the sieve holes, and then directly forms a soil pile through the unearthing belt conveyor; the larger materials enter the impact crusher through the screening feeder for crushing, and when the particle size reaches the standard, it is discharged from the discharge port and enters the vibrating unloader.

| Model | Feeder | Impact Crusher | Main Belt | Side Discharge Belt | Inspection Screen | Discharge Belt Under Screen | Transition Belt1 | Transition Belt2 | Screen Front Side Discharge Belt | Return Belt Conveyor | Capacity |

|---|---|---|---|---|---|---|---|---|---|---|---|

| YMCI10S | GZD9538 | CI1110 | B1000x10m | B500x3.8m | 2YK1436 | B1200x6.5m | B500x2m | B500x2m | B500x4.5m | B500x8.2m | 100-200t/h |

| YMC12S | GZD1135 | CI1213 | B1000x10m | B500x3.8m | 2YK1436 | B1200x6.5m | B500x2m | B500x2m | B500x4.5m | B500x8.2m | 150-300t/h |

| YMCI12 | GZD1135 | CI1213 | B1000x10m | B500x3.8m | — | — | — | — | — | — | 150-300t/h |

| YMCI13S | GZD1235 | CI1313 | B1200x10m | B500x3.8m | 2YK1436 | B1200x6.5m | B500x2m | B500x2m | B500x4.5m | B500x8.6m | 220-500t/h |

| YMCI13 | GZD1235 | CI1313 | B1200x10m | B500x3.8m | — | — | — | — | — | — | 220-500t/h |

Have Any Questions!

Don't Hesitate To Contact Us AnyTime.

If you need further information,please fill in your questions and comments in the form below.

Representatives from Baichy machinery will be back to you within the hour,thanking you for your support to Baichy machinery