The mobile impact crushing plant has broad application prospects in the field of crushing operations due to its high flexibility, efficient crushing capacity, wide adaptability, cost saving, environmental protection performance, and easy operation.

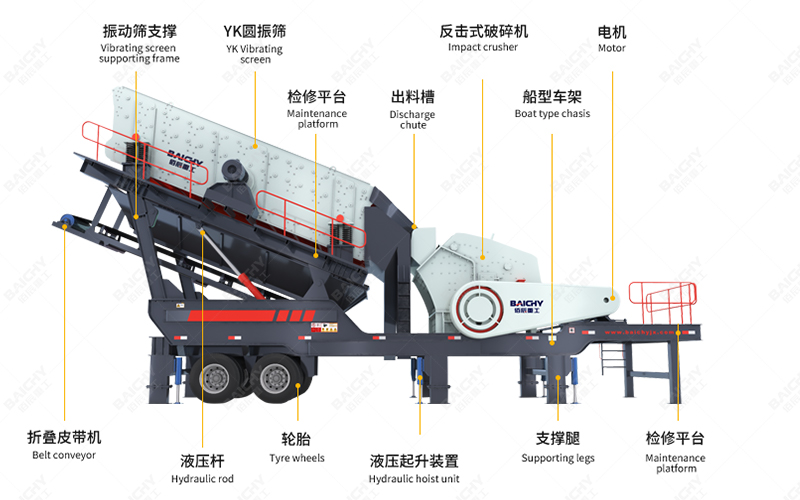

Mobile impact crusher, also known as a mobile crusher, mobile stone crusher, etc., is a mobile crushing equipment with an impact crusher as the main machine, integrating multiple pieces of equipment together to form a movable crushing production line.

The equipment can be flexibly moved and adjusted according to the changes in the production site and is suitable for a variety of material processing scenarios that require mobile crushing.

In the sand and gravel production line, the mobile impact crushing station has the advantages of good particle shape and high production efficiency. It is suitable for crushing various medium-hard stones; it is an efficient and flexible crushing equipment.

The equipment is reasonably matched, the whole line process is unobstructed, the operation is convenient, and it is easy to maintain and maintain.

The mobile impact crusher uses an impact crusher as the main machine. The crusher is famous for its powerful crushing capacity and can efficiently process materials of various hardness, including granite, limestone, diabase, basalt, andesite, etc.

Mobile impact crusher has extremely high mobility and can be extended with the raw material site or construction site, which is convenient for transfer and operation. It can adjust its position according to the change of production site and is suitable for a variety of material processing scenarios that require mobile crushing.

First, raw materials (such as ores, rocks, construction waste, etc.) are fed into the silo of the mobile impact crushing station through forklifts, excavators, and other equipment. These raw materials then enter the screening feeder, where the smaller part of the raw materials will leak directly through the screen holes and be directly formed into mounds or further processed by the excavating belt conveyor.

Materials with larger particle sizes continue to enter the impact crusher through the screening feeder. In the impact crusher, the motor drives the rotor to rotate at high speed through the triangle belt. The plate hammer on the rotor radiates under the action of centrifugal force. When the material enters the rotating range of the plate hammer, it is impacted by the high-speed rotating plate hammer. The material is thrown to the impact plate along the tangential direction of the plate hammer for impact. This impact process causes the material to be continuously impacted and squeezed in the crushing cavity, causing damage to its internal organization, thereby achieving crushing.

| SMC Impact crusher | SMC1010PFS | SMC1210PFS | SMC1214PFS | |

| Transport size | ||||

| Length(mm) | 10800 | 12200 | 12500 | |

| Width(mm) | 2480 | 2743 | 2900 | |

| Height(mm) | 4170 | 4200 | 4200 | |

| Alex weight(kg) | 15900 | 17200 | 22100 | |

| King pin weight(kg) | 11300 | 14300 | 17500 | |

| Impact crusher | ||||

| Model | PF1010 | PF1210 | PF1214 | |

| Feed opening(mm) | 400X1080 | 400X1080 | 400X1080 | |

| Vibrating screen | Vibrating screen | |||

| Model | 4YK1235 | 4YK1545 | 4YK1548 | |

Have Any Questions!

Don't Hesitate To Contact Us AnyTime.

If you need further information,please fill in your questions and comments in the form below.

Representatives from Baichy machinery will be back to you within the hour,thanking you for your support to Baichy machinery