Track-mounted Mobile Jaw Crusher, also known as crawler mobile jaw crusher, has a wide range of application scenarios in many fields due to its high efficiency, convenience, flexibility, and environmental protection.

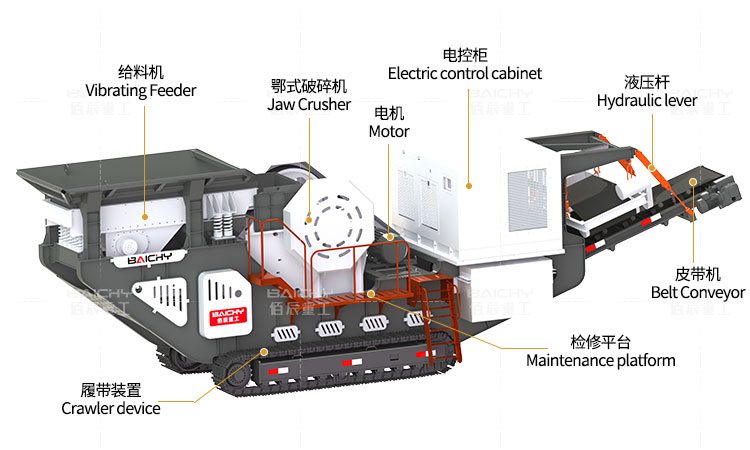

Crawler jaw crusher is a mobile crushing and screening equipment that walks on a chassis. It uses a crawler walking device, has excellent mobility and flexibility, can easily cross various complex terrains, and can operate flexibly in a small space. The equipment integrates process equipment such as receiving, crushing, and conveying, with a solid structure and reliable operation.

Crawler jaw crushers are widely used in many fields, including road and bridge construction, urban construction, metallurgy, energy, recycling and reuse of construction waste, open-pit mining, and tunnel crushing. Such as rock, ore, iron ore, copper ore, concrete waste, etc., with unique mobility, efficient crushing capacity and a wide range of applications.

The Track-mounted Mobile Jaw Crusher can easily handle hard materials in the mine, such as rocks, ores, etc., and perform coarse and fine crushing operations to provide suitable material particle size for subsequent processing. In open-pit mining operations, the crawler station can be flexibly moved to the operation site to perform efficient crushing operations and improve mining efficiency.

The Track-mounted Mobile Jaw Crusher is designed to crush materials nearby, providing customers with convenient, efficient, and low-cost installation. According to the requirements of different crushing processes, the program of crushing first and then sieving or first sieving and then crushing can be selected, which is flexible in use and can meet the needs of customers to the greatest extent.

Vibrating feeders allow for optimal pre-scaling and uniform feeding. The crusher can be equipped with Jaw Crusher, Impact Crusher, Cone Crusher, VSI Crusher, etc. A diesel direct drive is combined with an electric motor for maximum performance in a small space. Optional magnetic separator, unloading belt, and water spray system.

| Model | Feeder | Jaw Crusher | Main Discharge Belt | Side Discharge Belt | Capacity |

|---|---|---|---|---|---|

| YMC80 | G2D8035 | C80 | B800x9m | B500x3.8m | 80-125t/h |

| YMC96 | G2D9638 | C96 | B1000x12m | 100-250t/h | |

| YMC106 | G2D1142 | C106 | 160-360t/h | ||

| YMC116 | C116 | B1200x13m | 200-450t/h | ||

| YMC120 | G2D1242 | C120 | 300-520t/h |

Have Any Questions!

Don't Hesitate To Contact Us AnyTime.

If you need further information,please fill in your questions and comments in the form below.

Representatives from Baichy machinery will be back to you within the hour,thanking you for your support to Baichy machinery