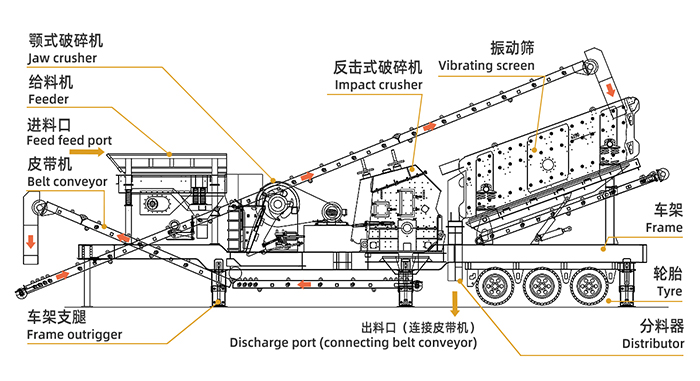

The jaw crusher + impact crusher four-combination mobile crushing station has been widely used in many industries such as mining, building materials, and solid waste treatment due to its advantages such as efficient crushing, flexible adaptability, energy saving, and economy, intelligent automation, and environmental protection and safety.

The jaw crusher is responsible for the coarse crushing stage, which can handle large pieces of material and break them into smaller pieces; the impact crusher further crushes the coarsely crushed products to the required fineness, thereby optimizing the particle size distribution.

By combining the jaw crusher and the impact crusher, optimizing equipment selection, adjusting crushing parameters, strengthening equipment maintenance, and adopting new technologies, the crushing power can be significantly increased, production efficiency can be improved, and production costs can be reduced.

The four-combination mobile crushing station can be flexibly combined into a "crushing first and then screening" or "screening first and then crushing" process according to different crushing process requirements. The mobile crushing station can be quickly transferred to different work sites to adapt to various terrains and environmental conditions.

The jaw crusher and the impact crusher each bear different operating loads during the crushing process, which helps to reduce overall energy consumption. Compared with traditional fixed crushing stations, the four-combination mobile crushing station reduces infrastructure construction investment, such as foundations and plant buildings.

Reduce the operating load of the impact crusher: The coarse crushing effect of the jaw crusher breaks large pieces of material into smaller pieces, reducing the operating load of the impact crusher, thereby increasing the overall crushing power.

Optimize particle size distribution: The particle size distribution of the crushed product of the jaw crusher is relatively wide, while the impact crusher can further adjust and optimize the particle size distribution to ensure that the product particle size meets the requirements.

Improve overall crushing efficiency: The combined use can give full play to the advantages of the two crushers, improve the overall crushing efficiency, and shorten the crushing time.

| Model | YDPZ46-1007 | YDPZ46-900 | YDPZ57-1210 | YDPZ57-75 | YDPZ96-1214 | YDPZ96-160 |

| Vibrating Feeder | ZSW0625 | ZSW0625 | ZSW8530 | ZSW8530 | ZSW9638 | ZSW9638 |

| Primary Jaw Crusher | PE400×600 | PE400×600 | PE500×750 | PE500×750 | CJ96 | CJ96 |

| Feeding Size (mm) | ≤350 | ≤350 | ≤425 | ≤425 | ≤480 | ≤480 |

| Feeding Size (mm) | 15-60 | 15-60 | 40-130 | 40-130 | 60-160 | 60-160 |

| Secondary Crusher | Impact crusher | Cone crusher | Impact crusher | Cone crusher | Impact crusher | Cone crusher |

| Model | PF1007 | PYB900 | PF1210 | CS75 | PFW1214 | CS160 |

| Feeding Size (mm) | ≤250 | ≤115 | ≤400 | ≤150 | ≤430 | ≤205 |

| Capacity (t/h) | 15-60 | 15-90 | 70-130 | 27-163 | 100-180 | 109-349 |

| Vibrating Screen | 2/3/4YK1237 | 2/3/4YK1237 | 2/3/4YK1848 | 2/3/4YK1848 | 2/3/4YK1860 | 2/3/4YK1860 |

| Belt Conveyor | B500x8m | B650 | B650 | B650 | B800 | B800 |

| Capacity (t/h) | 15-60 | 15-60 | 60-100 | 100-150 | 150-180 | 180-300 |

| Overall Size(mm) | 11500*2050*5400 | 11500*2050*5400 | 15800*2300*5850 | 15800*2300*5850 | 18000*2700*7650 | 18000*2700*7650 |

Have Any Questions!

Don't Hesitate To Contact Us AnyTime.

If you need further information,please fill in your questions and comments in the form below.

Representatives from Baichy machinery will be back to you within the hour,thanking you for your support to Baichy machinery