Analysis of the whole process of gold flotation extraction process

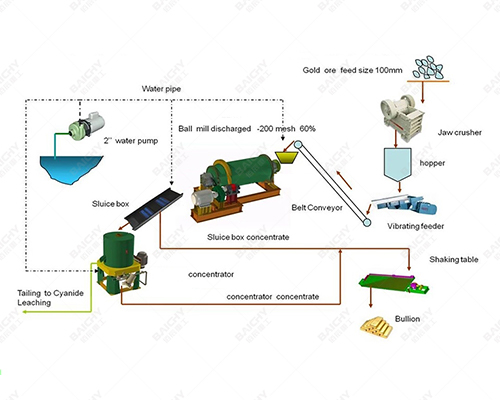

1. Ore pre-processing system

• Crushing stage: adopt a three-stage crushing process, the jaw crushercompletes the coarse crushing (≤150mm), the cone crusher performs the medium and fine crushing (≤30mm), and finally the ball mill is wet-grinded to less than 0.074mm (200 mesh), achieving the process requirement of monomer dissociation degree >85%.

• Key equipment: jaw crusher → hydraulic cone crusher → overflow ball mill (equipped with spiral classifier, closed loop)

2. Slurry conditioning system

Agents:

• Collector: butyl/isoamyl xanthate (50-200g/t), enhances the adsorption energy of the gold surface through the hydrophobic effect

• Foaming agent: MIBC methyl isobutyl carbinol (10-50g/t), to control the stability of the foam layer

• pH regulator: lime milk (maintain pH 8.5-10.5), inhibit pyrite from floating

• Dynamic slurry conditioning: adopt a three-stage series stirring tank (residence time>15min), slurry concentration is regulated in the solid content range of 25-35%, equipped with an online pH/ORP monitoring system to achieve closed-loop control

3. Flotation separation system

Core mechanism: Based on the difference in wettability of mineral surfaces, hydrophobic gold particles are modified by reagents (contact angle > 65°) and selectively attached with microbubbles (diameter 0.8-1.2mm) under aeration stirring conditions (impeller linear speed 6-8m/s) to form a mineralized foam layer.

Equipment selection:

• Roughing section: KYF type aerated mechanical stirring flotation machine (single tank volume 16m³)

• Sweeping section: JJF type self-priming flotation machine

• Concentration section: flotation column (height 6-8m, countercurrent flushing water system)

4. Concentrate enrichment system

Multi-stage concentration process:

• The foam product is concentrating three times (the concentrate grade is increased to 40-80g/t)

• Regrinding and re-selection of medium ore (vertical mill fineness -400 mesh>95%)

• Dehydration bin pre-concentration (bottom flow concentration>60%)

Process intensification: The new cyclone microbubble flotation unit is used to increase the recovery rate of -20μm fine gold by 12-15%.

5. Solid-liquid separation system

Combined dehydration process:

• Stage 1: High-efficiency deep cone concentrator (processing capacity 50t/h·m², underflow concentration 70%)

• Stage 2: Plate and frame filter press (feed pressure 0.8MPa, filter cake moisture content <18%)

Special working conditions: Centrifugal dehydrator for ultrafine particle size (-10μm >30%)

6. Metal extraction system

Pyrometallurgical-wet process:

• Smelting system: Oxygen-enriched side-blown smelting furnace (1250-1300℃), gold and silver recovery rate >98%

• Wet refining: Aqua Regia leaching → activated carbon adsorption → electrolytic deposition (purity ≥99.99%)

• Environmental protection treatment: SO₂ flue gas acid production + cyanide three-stage cyanide breaking device