Marble is a kind of recrystallized limestone which softens under high temperature and pressure re-crystallizing to form marble as the minerals change.

The leftover material of marble has high value for secondary use, which can be processed into fines and widely used in the chemical industry.

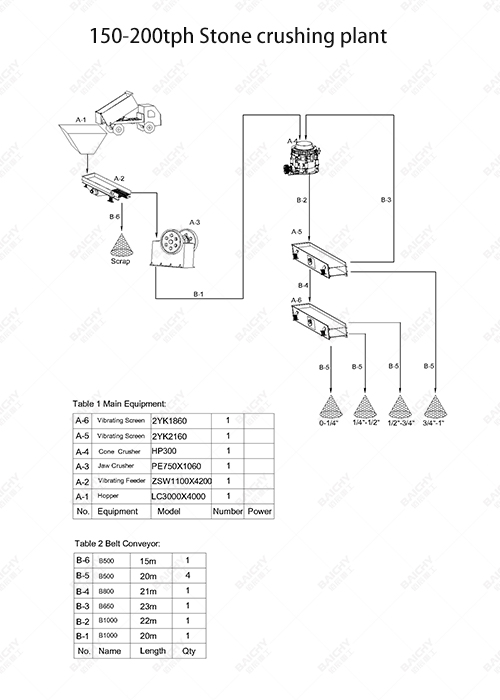

PE750x1060 Jaw Crusher, 2YZS2160 Vibrating Screen, 2YZS1860 Vibrating Screen, HPC300 Hydraulic Cone Crusher.

The stone is roughly crushed by the PE750x1060 Jaw Crusher, then sent to the HPC300 hydraulic cone crusher for secondary crushing, and finally, the finished product is screened and transported to the finished product pile by conveyor belt.

You can configure the number of layers of the vibrating screen according to your needs; if you need to make sand, you can choose a VSI sand-making machine to output 0-5mm sand.

Baichy Heavy Industry provides customers with free process design, from on-site commissioning and installation, equipment trial operation, technical support, and maintenance of the overall solution.