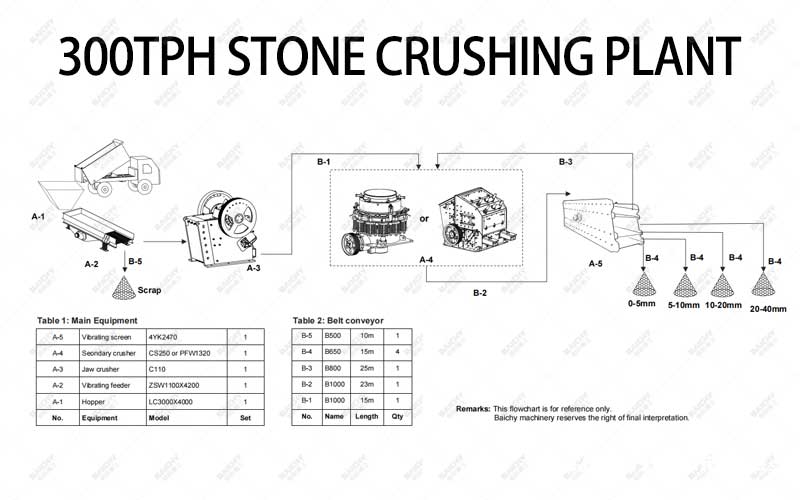

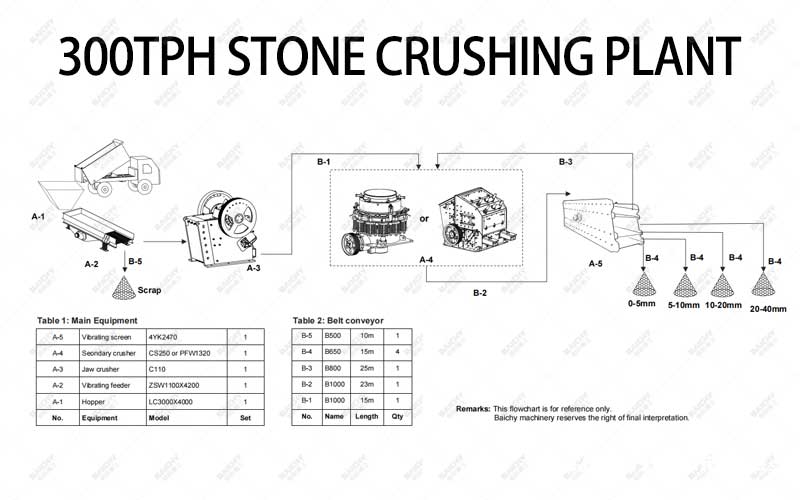

300tph crushing production line configuration: ZSW1142 feeder, C110 jaw crusher, CS250 cone crusher or PFW1320 impact crusher and 4YK2470 vibrating screen and belt conveyor equipment, etc.

300tph crushing production line equipment configuration and performance

1. ZSW1142 vibrating feeder

• Processing capacity: 120-380t/h, meeting the production needs of 300tph.

• Maximum feed particle size: 0.65m, ensuring that large pieces of material can enter the crushing process smoothly.

• Main applications: widely used in crushing and screening combined equipment in metallurgy, coal mining, mineral processing, building materials, chemical industry, abrasives and other industries.

2. C110 jaw crusher

• Production capacity: 190-625kg/h (converted to 190-625t/1000h, which is 10 times of 0.19-0.625t/h, about 190-625t/day. Considering that the crusher usually does not run at full capacity all day and this data is the theoretical maximum value, it can be considered suitable for production lines with higher capacity, including 300tph production lines), which can meet the needs of 300tph production lines.

• Feeding size: 850-1100mm, capable of handling large pieces of material.

• Discharging size: 70-200mm, which can be changed by adjusting the crusher parameters.

• Power consumption: 160kW, high energy efficiency.

3. CS250 cone crusher or PFW1320 impact crusher

CS250 cone crusher

• Production capacity: 1800kg/h (converted to 10 times 1.8t/h multiplied by 24 hours, about 43.2t/day, but considering that the crusher usually does not run at full load all day, and the cone crusher is often used in the medium and fine crushing stage, its processing capacity works in coordination with other equipment in the entire production line, and theoretically it can be applied to a 300tph production line).

• Discharge particle size: 5mm~10mm, with a high degree of fine grinding.

• Feed particle size: 200mm, suitable for the medium and fine crushing stage.

• Power consumption: 110kW, good energy efficiency.

PFW1320 impact crusher

• Processing capacity: 180-350t/h, meeting the production needs of 300tph.

• Feed opening size: 600*2030mm, capable of handling large pieces of material.

• Maximum feed size: 350mm, ensuring that the material can enter the crushing chamber smoothly.

• Motor power: 300-355kW, strong power.

5. 4YK2470 vibrating screen

• Processing capacity: 80-800t/h, far exceeding the demand of 300tph, ensuring the smooth operation of the production line.

• Number of screen layers: 4 layers, multi-level screening can be achieved.

• Screen area: 14.4㎡, high screening efficiency.

• Screen hole size: 5-80mm (customizable), the screening particle size can be adjusted according to needs.

6. Belt conveyor equipment

• Main function: responsible for the transportation of materials in the production line and improving the degree of automation.

• Quantity and length: to be determined according to the actual situation of the work site.

300tph crushing production line equipment configuration recommendations

1. Equipment selection: The above equipment selection is based on the production demand of 300tph, and takes into account key parameters such as equipment processing capacity, feed particle size, and discharge particle size.

2. Equipment layout: It should be reasonably laid out according to the actual situation of the work site to ensure the smooth flow of materials and facilitate the operation and maintenance of the equipment.

3. Collaborative work: Good collaborative work should be achieved between the various equipment to ensure the overall efficiency and stability of the production line.

4. Safety and environmental protection: Necessary safety and environmental protection equipment, such as dust collectors, noise reduction devices, etc., should be configured to ensure the safe and environmentally friendly operation of the production line.

The equipment configuration plan for the 300tph crushing production line can meet the needs of the 300tph crushing production line, and has been comprehensively considered in terms of processing capacity, equipment selection, layout and collaborative work.

Overall cost estimation of a complete crusher production line with a capacity of 300 tons per hour

Taking into account the above factors, the cost of a complete crusher production line with a capacity of 300 tons per hour may range from hundreds of thousands to millions of RMB. The specific cost needs to be determined based on the actual needs of the customer, equipment selection, brand selection, and the actual situation of the production site.

In order to reduce the cost of the production line, customers can consider the following points:

1. Reasonable selection of equipment: Reasonable selection of equipment model and brand based on material characteristics, production requirements and budget.

2. Optimize the layout of the production line: By optimizing the layout of the production line, reduce the number and length of unnecessary equipment, thereby reducing equipment costs.

3. Select high-quality suppliers: Select qualified, experienced and reputable suppliers to cooperate to ensure equipment quality and after-sales service.

4. Strengthen equipment management: Regularly maintain and service the equipment to extend the service life of the equipment and reduce maintenance costs.

The cost of a complete crusher production line with a capacity of 300 tons per hour is a complex combination of factors, which needs to be determined by considering multiple aspects.

FAQ about 300 tons per hour crushing production line

1. How much space is required for a crushing production line of 300 tons per hour?

Depending on the compactness of the layout, a site of 50 meters × 30 meters (about 1500 square meters) is usually required, including equipment installation, material stacking, and transportation channels. Mobile production lines can reduce site requirements.

2. What materials are suitable for crushing?

• Hard rock (granite, basalt): A jaw crusher + cone crusher combination is recommended.

• Medium hard/soft rock (limestone, coal gangue): An impact or hammer crusher can be used.

• Construction waste: an iron remover and a light material separator are required.

3. What is the energy consumption of the production line?

The total power is about 400- 600 kW (taking domestic equipment as an example), and the power consumption is about 15-25 degrees/ton, depending on the hardness of the material and the crushing ratio.

4. How to control dust and noise?

• Dust: Spray system + pulse bag dust collector (emission concentration ≤ 20mg/m³).

• Noise: Equipment is equipped with a soundproof cover, and the site is equipped with a soundproof wall (controlled below 85dB).

5. What should I do if the production line capacity does not reach 300 tons/hour?

• Uneven feeding: Adjust the frequency of the vibrating feeder.

• Improper crusher selection: Check whether the discharge port size matches.

• High material moisture: Pre-screen or reduce the feeding speed.